MTEC, FDA projects to develop new tool for stem cell, CAR T-cell manufacturing

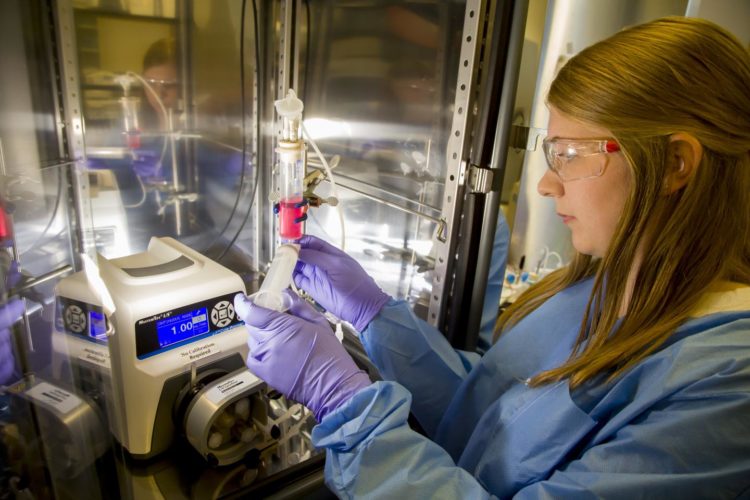

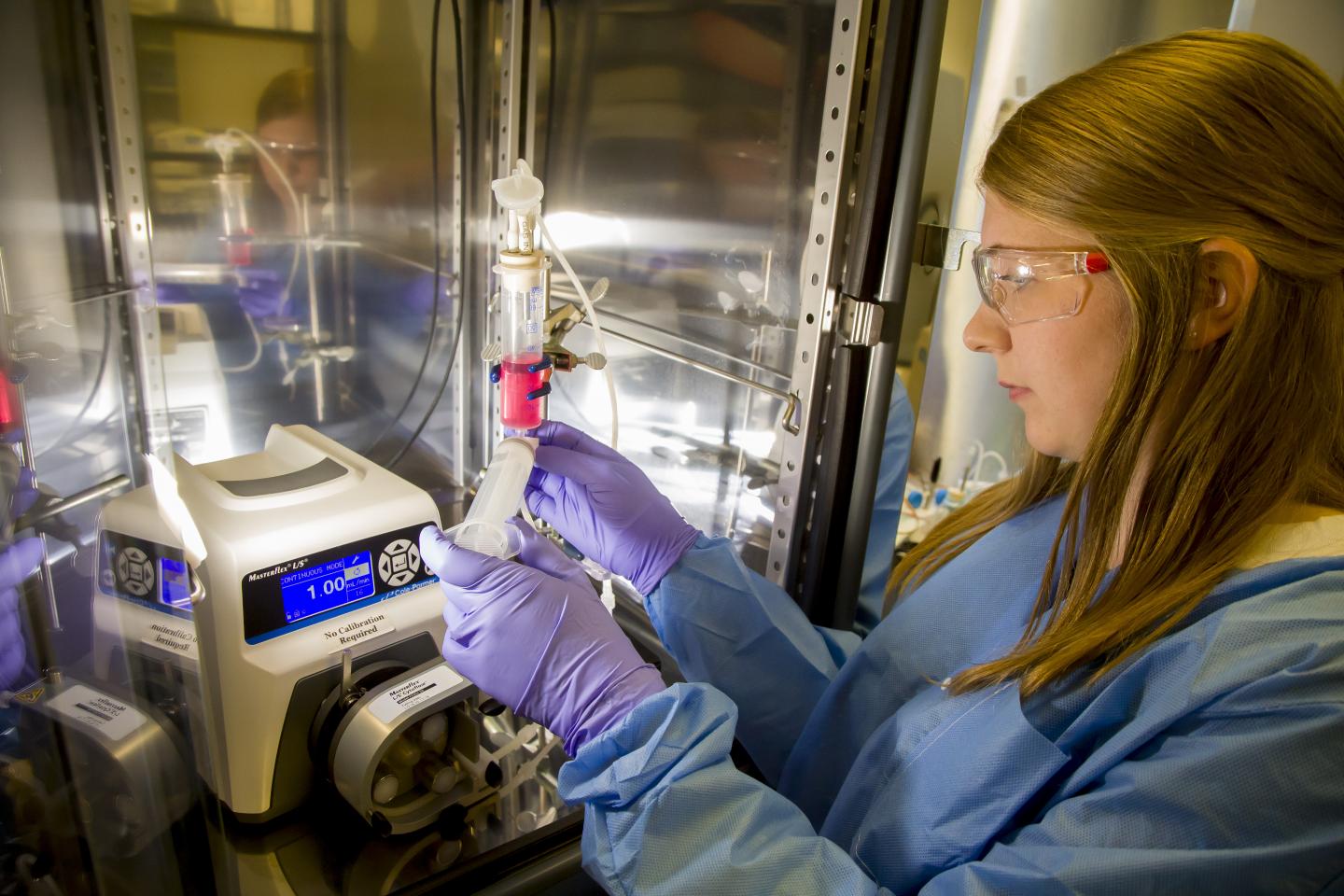

Credit: Southwest Research Institute

SAN ANTONIO — Oct. 8, 2019 — Southwest Research Institute has received new funding from the Medical Technology Enterprise Consortium (MTEC) and the Food and Drug Administration (FDA) to use an SwRI-developed bioreactor to propagate cells for personalized regenerative medicine applications. A $3 million MTEC program will demonstrate stem cell manufacturing, and a $2.3 FDA contract is funding CAR T-cell production.

Cell and gene therapies hold the promise of revolutionizing treating diseases using a patient’s own immune or stem cells. But existing technologies don’t meet clinical needs for high-quality and cost-effective cell manufacturing. They typically require an expensive, labor-intensive cell culture process in high-cost clean room conditions.

Now, SwRI bioengineers have invented a novel bioreactor to propagate cells for tomorrow’s personalized medical treatments using cell and gene therapy. Fabricated using 3D printers, these single-use devices can expand cells in a closed-loop automated system with minimum human interactions and in a low-cost cleanroom, increasing yields while reducing costs.

“Much like a single serve coffee maker can brew a variety of beverages using K-cup® pods, we’re developing a turnkey perfusion-based ‘cell maker’ system that can propagate a variety of different types of cells and cell-derived biologics using SwRI’s single-use bioreactors,” said Dr. Jian Ling, an Institute scientist leading the development. “This cell expansion platform will be integrated into new drug manufacturing systems expected to have a high impact on advancing personalized, regenerative medicine.”

Personalized medicine turbocharges the body’s own defenses, using genetically modified cells to attack a specific disease or repair an injury. This type of regenerative therapy could revolutionize how physicians treat diseases and degeneration using a patient’s own immune or stem cells to fashion targeted treatments. For instance, a patch of stem cells could be used to repair a heart valve. Or T-cells in the immune system could be modified to seek out and destroy cancer cells. However, the promise of personalized, regenerative medicine is limited, in part, by scale. For example, only about 100,000 stem cells with regenerative potential can be harvested in an autologous or self donation, but effective treatments often require a billion cells for a single dose, requiring a 10,000-fold increase for clinical applications.

“Existing technologies do not meet the clinical needs for cell manufacturing,” Ling said. “These applications typically require an expensive, labor-intensive cell culture process in high-cost cleanroom conditions.”

In contrast, SwRI’s bioreactor facilitates pump-driven perfusion flow-based cell cultures. Perfusion technology mimics the human circulatory system to provide nutrition and oxygen to cells to support growth. SwRI’s automated three-bioreactor-based system can replace hundreds of manual-operation flasks to propagate 1 billion cells.

“Currently, the SwRI team is assembling the perfusion controller system and optimizing the production processes,” Ling said. “We are establishing clean-room fabrication and sterilization procedures for the bioreactor, while demonstrating the capabilities for clinical cell manufacturing. At the end of this program, a sterile fabricated bioreactor, integrated with a programmable perfusion system, will be available for clinical cell manufacturing.”

###

This research, based on an SwRI internal research program that developed the bioreactor technology, is also supported by other government funding.

For more information, go to https:/

Media Contact

Deb Schmid

[email protected]

210-522-2254

Original Source

https:/