Credit: University of Illinois at Urbana-Champaign Department of Aerospace Engineering

Additive manufacturing built an early following with 3D printers using polymers to create a solid object from a Computer-Aided Design model. The materials used were neat polymers–perfect for a rapid prototype, but not commonly used as structural materials.

A new wave of additive manufacturing uses polymer composites that are extruded from a nozzle as an epoxy resin, but reinforced with short, chopped carbon fibers. The fibers make the material stronger, much like rebar in a cement sidewalk. The resulting object is much stiffer and stronger than a resin on its own.

The question a recent University of Illinois at Urbana-Champaign study set out to answer concerns which configuration or pattern of carbon fibers in the layers of extruded resin will result in the stiffest material.

John Lambros, Willett professor in the Department of Aerospace Engineering and director of the Advanced Materials Testing and Evaluation Laboratory at U of I was approached by an additive manufacturing research group at Lawrence Livermore National Laboratory to test composite parts that they had created using a direct ink writing technique.

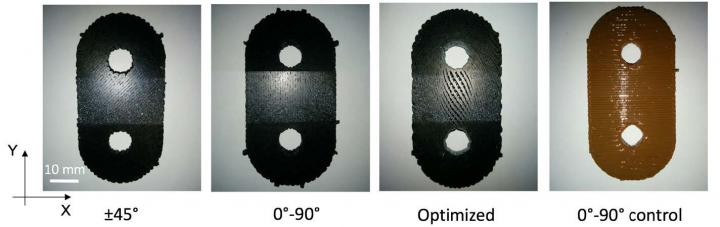

“The carbon fibers are small, about seven microns in diameter and 500 microns in length,” Lambros said. “It’s easier with a microscope but you can certainly see a bundle with the naked eye. The fibers are mostly aligned in the extruded resin, which is like a glue that holds the fibers in place. The Lawrence Livermore group provided the parts, created with several different configurations and one made without any embedded fibers as a control. One of the parts had been theoretically optimized for maximum stiffness, but the group wanted definitive experimental corroboration of the optimization process.”

Lambros said that while waiting for the actual additively manufactured composite samples, Lambros and his student made their own “dummy” samples out of Plexiglas, and that way could begin testing the dummies.

In this case, the shape being tested was a clevis joint–a small, oval-shaped plate with two holes used to connect two other surfaces. For each different sample shape, Lambros’ lab must create a unique loading fixture to test it.

“We create the stands, the grips, and everything–how they’ll be painted, how the cameras will record the tests, and so on,” Lambros said. “When we got the real samples, they weren’t exactly the same shape. The thickness was a bit different than our Plexiglas ones, so we made new spacers and worked it out in the end. From the mechanics side, we must be very cautious. It’s necessary to use precision so as to be confident that any eventual certification of additively manufactured parts is done properly.”

“We created an experimental framework to validate the optimal pattern of the short-fiber reinforced composite material,” Lambros said. “As the loading machine strained the clevis joint plates, we used a digital image correlation technique to measure the displacement field across the surface of each sample by tracking the motion in the pixel intensity values of a series of digital images taken as the sample deforms. A random speckle pattern is applied to the sample surface and serves to identify subsets of the digital images in a unique fashion so they can be tracked during deformation.”

They tested one control sample and four different configurations, including the one believed to be optimized for stiffness, which had a wavy fiber pattern rather than one oriented along horizontal or vertical lines.

“Each sample clevis joint plate had 12 layers in a stack. The optimized one had curved deposition lines and gaps between them,” Lambros said. “According to the Livermore group’s predictions, the gaps are there by design, because you don’t need more material than this to provide the optimal stiffness. That’s what we tested. We passed loading pins through the holes, then pulled each sample to the point of breaking, recording the amount of load and the displacement.

“The configuration that they predicted would be optimal, was indeed optimal. The least optimal was the control sample, which is just resin–as you would expect because there are no fibers in it.”

Lambros said that there is a premise in the analysis that this is a global optimum–meaning that this is the absolutely best possible sample built for stiffness–no other build pattern is better than this one.

“Although of course we only tested four configurations, it does look like the optimized configuration may be the absolute best in practice because the configurations that would most commonly be used in design, such as 0°-90° or ±45° alignments, were more compliant or less stiff than what this one was,” Lambros said. “The interesting thing that we found is that the sample optimized to be the stiffest also turned out to be the strongest. So, if you look at where they break, this one is at the highest load. This was somewhat unexpected in the sense that they had not optimized for this feature. In fact, the optimized sample was also a bit lighter than the others, so if you look at specific load, the failure load per unit weight, it’s a lot higher. It’s quite a bit stronger than the other ones. And why that is the case is something that we’re going to investigate next.”

Lambros said there may be more testing done in the future, but for now, his team successfully demonstrated that they could provide a validation for the optimized additive composite build.

###

Media Contact

John Lambros

[email protected]

Original Source

http://ae.

Related Journal Article

http://dx.