West Virginia University engineers have received a wave of federal support for research projects that will help slash the cost of clean hydrogen.

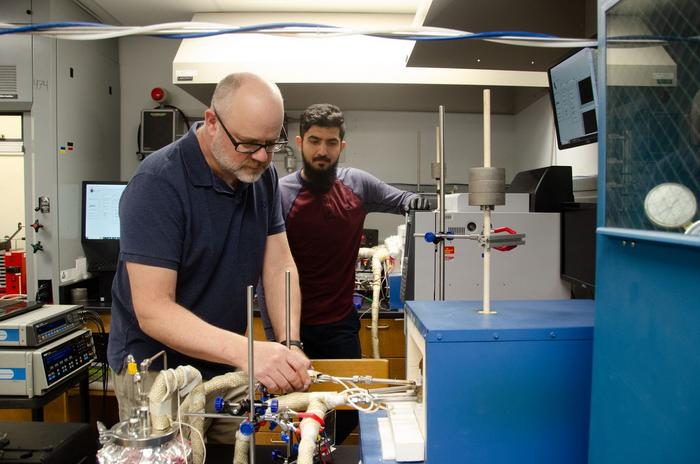

Credit: WVU Photo/Savanna Leech

West Virginia University engineers have received a wave of federal support for research projects that will help slash the cost of clean hydrogen.

The three U.S. Department of Energy grants for WVU studies total $15.8 million and are part of funds authorized by the Bipartisan Infrastructure Law for research that advances the “Hydrogen Shot” goal of cutting the cost of clean hydrogen production to $1 per kilogram.

The projects happening at the WVU Benjamin M. Statler College of Engineering and Mineral Resources all focus on improving the manufacture or design of a technology called the “solid oxide electrolysis cell” or SOEC. SOECs split water into hydrogen and oxygen through the process of electrolysis, which is powered by electricity that can come from renewable energy sources.

Edward Sabolsky, professor in the Department of Mechanical, Materials and Aerospace Engineering, received $9.3 million in DOE support to design a furnace for SOEC manufacturing that uses microwave energy for heat.

In the same department, Xingbo Liu, professor, associate dean for research and Statler Chair of Engineering, leads a research group that received $4.5 million to develop a “proton-conducting” SOEC capable of outperforming conventional “oxygen-conducting” SOECs.

Wenyuan Li, assistant professor in the Department of Chemical and Biomedical Engineering, received $2 million for WVU contributions to a three-year study. Like Sabolsky, Li is looking at better ways to manufacture SOECs. However, he’s focused not on microwaves, but on a process called “ultrafast high-temperature sintering,” which can achieve temperatures up to 2,000 degrees Celsius within minutes. Compared to a conventional system, Li’s design improves energy and time efficiency while reducing carbon emissions, energy consumption and costs for capital, maintenance and labor.

“The different WVU teams are each taking their own approach,” Sabolsky said. “Our shared goal is to develop these SOEC systems to produce hydrogen, which would then be implemented into all the industries that currently use fossil energy sources for manufacturing and transportation. One example would be to replace the industrial fuel coke with hydrogen when processing steel. This would remove the use of carbon, a major driver of climate change.”

Sabolsky explained that “electrolysis is positioned to replace the traditional hydrogen generation technology, steam methane reforming, which produces significant greenhouse gases. SOECs can operate at up to 100% efficiency and run on waste heat from adjacent industrial processes.”

To make SOECs, multiple ceramic layers need to be processed to temperatures between 1,000 and 1,400 degrees Celsius. According to Sabolsky, that process is time-consuming and energy intensive.

“It typically takes nearly a week to heat up and cool down the materials multiple times,” he said. “We need a method that’s much more efficient if we’re going to commercialize SOECs at the level the DOE Hydrogen Shot requires in the next five years.”

That’s why Sabolsky is replacing traditional thermal processing with “microwave-assisted processing.”

“In traditional thermal processing, energy heats an element in a furnace, then that heat is transferred into the product we want to make hot,” he said. “When we use microwaves, the energy goes directly into the product, improving heating rates and energy efficiency. Using materials called ‘susceptors’ to ensure irregularities in a material don’t cause the microwaves to heat it unevenly, our lab has demonstrated SOEC fabrication using only 10% of the energy and 10% of the time compared to standard thermal processing.”

Sabolsky is conscious that commercialization of his technology can create job opportunities and stimulate local economic growth as Appalachia builds a regional infrastructure for hydrogen generation. Once the hardware is ready, his team will start demonstrating it to fuel cell companies, offering them a demonstration lab for testing the system on their proprietary ceramics. Sabolsky said he wants to see the first sales of the new furnace design less than a year after the four-year research period ends.

He foresees his furnace design can support the immediate launch of two startup companies in collaboration with the WVU Innovation Corporation, an incubation chamber for growing manufacturing and high technology jobs.

“One startup potentially will be an extension of an existing business, manufacturing parts of our system or our whole system within West Virginia,” he said. “The second would manufacture advanced electrical materials and powders, and high-temperature processing insulation and containers.”

Liu underlined the work happening at WVU “will help make this region a leader in the hydrogen economy. With the technologies researchers are developing, West Virginia is going to leverage the natural gas we have here in the Marcellus Shale to make cheap, clean hydrogen,” he said.

In 2023, Liu and his team received the DOE Hydrogen Program’s Hydrogen Production Technology Award for their work developing SOECs that conduct protons rather than oxygen ions. Now, he said, it’s time to build on that innovation and arrive at a high performance system that can run at a low temperature.

“We’re enhancing for efficiency, stability and performance. Our proton-conducting SOECs can be manufactured on a large scale with minimal complexity and cost. We expect this research to unlock the full potential of SOEC technology, supporting a future powered by clean, renewable hydrogen at $1 a kilogram.”

Additional faculty involved with the studies include GE Plastics Professor Debangsu Bhattacharyya; professor John Hu, Statler Chair in Engineering for Natural Gas Utilization and director of the WVU Center for Innovation in Gas Research and Utilization; associate professor Terence Musho; and associate professor Fernando Lima.