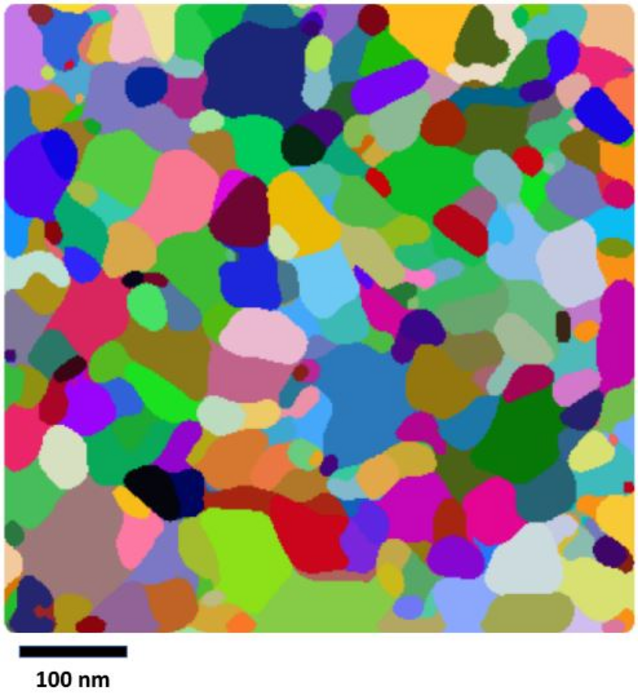

The orientations of these infinitesimally small separations between individual “grains” of a polycrystalline material have big effects. In a material such as aluminum, these collections of grains (called microstructures) determine properties such as hardness.

Credit: Courtesy of Lehigh University

The orientations of these infinitesimally small separations between individual “grains” of a polycrystalline material have big effects. In a material such as aluminum, these collections of grains (called microstructures) determine properties such as hardness.

New research is helping scientists better understand how microstructures change, or undergo “grain growth,” at high temperatures.

A team of materials scientists and applied mathematicians developed a mathematical model that more accurately describes such microstructures by integrating data that can be identified from highly magnified images taken during experiments. Their findings are published in Nature: Computational Materials.

The research team included Jeffrey M. Rickman, Class of ’61 Professor of Materials Science & Engineering at Lehigh University; Katayun Barmak, Philips Electronics Professor of Applied Physics and Applied Mathematics at Columbia University; Yekaterina Epshteyn, Professor of Mathematics at the University of Utah; and Chun Liu, Professor of Applied Mathematics at the Illinois Institute of Technology.

“Our model is novel because it is given in terms of features that can be identified from experimental micrographs, or photos that reveal the details of microstructures at a length scale of nanometers to microns,” Rickman said. “Because our model can be related to these experimental features, it is a more faithful representation of the actual grain growth process.”

The researchers conducted crystal orientation mapping on thin films of aluminum with columnar grains and used a stochastic, marked point process to represent triple junctions, points where three grains and grain boundaries meet in the structure. Their model is the first to integrate data on the interactions and disorientations of these triple junctions to predict grain growth.

Predicting grain growth is key to the creation of new materials and is a pivotal area of study in materials science. As a result, many models of grain growth have been developed. However, the project’s direct link between the mathematical model and the experimental micrographs is highly distinctive.

According to Rickman, linking the model directly to features that can be tracked during experiments will benefit computational materials scientists who model the kinetics of grain growth.

“Ultimately, this research provides a way to better understand how grain growth works and how it can be used to inform the development of new materials,” Rickman said.

The research was funded by the National Science Foundation under the prestigious Designing Materials to Revolutionize and Engineer Our Future (DMREF) program. Rickman is lead author of the research article, “Point process microstructural model of metallic thin films with implications for coarsening,” with Barmak, Epshteyn and Liu as co-authors.

Journal

npj Computational Materials

DOI

10.1038/s41524-023-00986-w

Method of Research

Computational simulation/modeling

Subject of Research

Not applicable

Article Title

Point process microstructural model of metallic thin films with implications for coarsening

Article Publication Date

25-Feb-2023