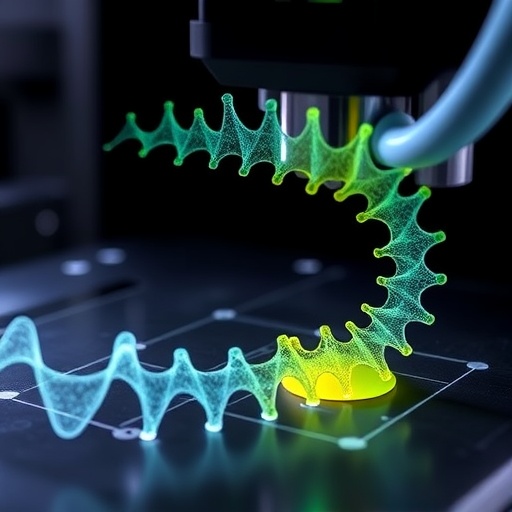

In the rapidly evolving domain of additive manufacturing, the integration of biofabrication techniques has opened new frontiers in tissue engineering and regenerative medicine. The latest breakthrough, reported by Griffin et al. in their groundbreaking work on 3D vector field-guided toolpathing, introduces a transformative approach to 3D bioprinting that promises higher fidelity, enhanced structural complexity, and improved biological functionality of printed constructs. This novel methodology, recently published in Communications Engineering, leverages vector field analysis to meticulously control the printing toolpath in three dimensions, thus overcoming some of the most persistent challenges in biofabrication.

Traditional 3D bioprinting relies heavily on layer-by-layer deposition methods, which often fail to replicate the intricacies of native biological tissues. These conventional techniques are limited by constraints such as anisotropic mechanical properties, suboptimal cell alignment, and insufficient vascularization within printed tissues. Griffin and colleagues introduce an innovative paradigm that harnesses vector fields—mathematical representations that assign a vector to every point in space—to guide the movement and orientation of the printing nozzle. This allows for a more biomimetic deposition of bioinks, tailoring the printed structure to closely mimic the architecture of natural extracellular matrices.

A key technical advancement in this work is the generation of 3D vector fields derived from computational models of tissue geometry and function. These fields encode critical directional information that informs the path of the print head in real time. By aligning printed fibers along these vectors, the researchers achieve precise control over fiber orientation, density, and spatial distribution. Such control is pivotal for engineering tissues that exhibit appropriate mechanical stiffness and anisotropy, two properties critical for functional integration within the host organism.

.adsslot_WkdR8Ox9jq{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_WkdR8Ox9jq{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_WkdR8Ox9jq{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

The process begins with a detailed computational simulation of the target tissue, incorporating biomechanical parameters and cellular organization cues. This simulation yields a vector field that represents optimal fiber orientations at each coordinate within the printing volume. Using specialized algorithms, the printing toolpath is then generated to follow these vectors, ensuring that bioink filaments are deposited with directional fidelity. Unlike conventional raster or spiral toolpaths, this vector-guided approach prevents the formation of structural discontinuities and enhances inter-fiber connectivity.

From a bioprinting hardware perspective, the implementation required adaptive control systems capable of modulating nozzle speed, extrusion rate, and orientation in three dimensions. To achieve this, Griffin et al. integrated advanced motion control algorithms with real-time feedback from positional sensors. This dynamic adjustment ensures that the print head consistently adheres to the prescribed vector field despite variations in bioink viscosity or environmental conditions. The interplay between computational guidance and mechanical precision is fundamental to the success of this novel toolpathing strategy.

Beyond purely mechanical improvements, the biological implications of vector field-guided toolpathing are profound. Tissues such as musculoskeletal ligaments, neural tracts, and vascular networks rely heavily on oriented structures for proper function. By bioprinting constructs whose microarchitecture matches these native orientations, the method enhances cellular alignment, which in turn promotes physiological remodeling and integration. Preliminary in vitro studies conducted by the team demonstrated improved cell proliferation and differentiation along the printed fiber directions, indicating a promising route toward functional tissue regeneration.

Another advantage highlighted by the study is the scalability of the technique. Because vector fields can be computed for complex geometries at multiple scales, the method is adaptable to printing constructs ranging from microscale capillary-like channels to macroscale organoid scaffolds. This flexibility is expected to accelerate the translation of bioprinting from benchtop models to clinical applications, where large-scale and patient-specific grafts are often required.

In addition to biological tissues, the vector field-guided toolpathing framework holds significant promise for soft robotics and biohybrid devices. The ability to program fiber directionality and density enables the fabrication of constructs with anisotropic mechanical responses tailored to mimic muscle tissue or flexible actuation components. This cross-disciplinary relevance underscores the wide-ranging impact of the technology beyond regenerative medicine alone.

One of the seminal challenges the researchers addressed is the integration of the requisite computational tools into existing bioprinting workflows. By developing open-source software that automates vector field calculation and toolpath generation, Griffin et al. have lowered the barriers for adoption across the bioprinting community. This software interoperates with popular slicing tools, making it compatible with many commercial bioprinters and facilitating easy incorporation into current biomanufacturing pipelines.

The study also sheds light on the material considerations necessary for vector field-guided bioprinting. Bioinks must exhibit shear-thinning behavior and rapid gelation to maintain precise filament shape during printing aligned with complex toolpaths. Griffin’s team experimented with composite hydrogels embedded with functionalized nanoparticles to achieve these rheological properties while maintaining cytocompatibility, highlighting the intricate relationship between material science and printpath architecture.

Critically, the authors acknowledge remaining limitations, including the challenge of vascularization within thick constructs and the mechanical robustness over long-term implantation. However, the integration of vector field-guided printing with emerging vascularization strategies—such as coaxial printing and sacrificial bioinks—provides a promising roadmap to surmount these issues. Furthermore, ongoing developments in high-throughput imaging and multiscale modeling are expected to refine vector field computations to even greater levels of biological relevance.

Looking toward future directions, the paper underscores opportunities for artificial intelligence integration to predict optimal vector fields based on patient-specific imaging data. Such synergy could enable fully personalized bioprinting solutions, dynamically adjusting toolpaths to individual anatomical and functional needs. Coupled with advances in stem cell biology and gene editing, this approach could revolutionize the production of living implants tailored to regenerate damaged tissues with unprecedented precision.

Moreover, the vector field-guided paradigm marks a conceptual shift from traditional additive manufacturing toward a more nature-inspired fabrication method. By embedding directional cues directly into the printing process, it aligns with the hierarchical organization observed in biological tissues, from collagen fibrils to whole organ systems. This biomimetic philosophy may herald a new era where form and function are co-designed at the microscale, enabling constructs with emergent properties previously unattainable via standard bioprinting.

The societal implications of such advancements are immense. As tissue shortages and organ failure continue to burden healthcare systems worldwide, technologies enabling the generation of functional bioartificial tissues could alleviate transplant waitlists and improve quality of life. The ability to create patient-specific grafts rapidly also reduces immune rejection risks and supports personalized medicine ambitions, translating scientific innovation into tangible clinical impact.

In summary, Griffin and colleagues present a pioneering vector field-guided toolpathing method for 3D bioprinting that elegantly combines computational modeling, material engineering, and precision robotics to enhance the fidelity and functionality of bioprinted tissues. Their work represents a significant leap forward in addressing the complexities of biological architecture within the additive manufacturing landscape. Future research and clinical translation building upon this framework are poised to reshape the possibilities of regenerative medicine and beyond.

Subject of Research: 3D Bioprinting, Vector Field-Guided Toolpathing, Tissue Engineering

Article Title: 3D vector field-guided toolpathing for 3D bioprinting

Article References:

Griffin, M.R., Bertram, S.E., Robison, N.P. et al. 3D vector field-guided toolpathing for 3D bioprinting. Commun Eng 4, 154 (2025). https://doi.org/10.1038/s44172-025-00489-0

Image Credits: AI Generated

Tags: 3D bioprinting techniquesadditive manufacturing applicationsanisotropic mechanical properties in tissuesbiofabrication advancementsbiological functionality of printed constructsbiomimetic deposition methodscomputational vector field generationenhanced structural complexity in bioprintingextracellular matrix architectureregenerative medicine breakthroughstissue engineering innovationsvector field-guided toolpaths