Physical chemistry: Publication in ACS Applied Materials & Interfaces

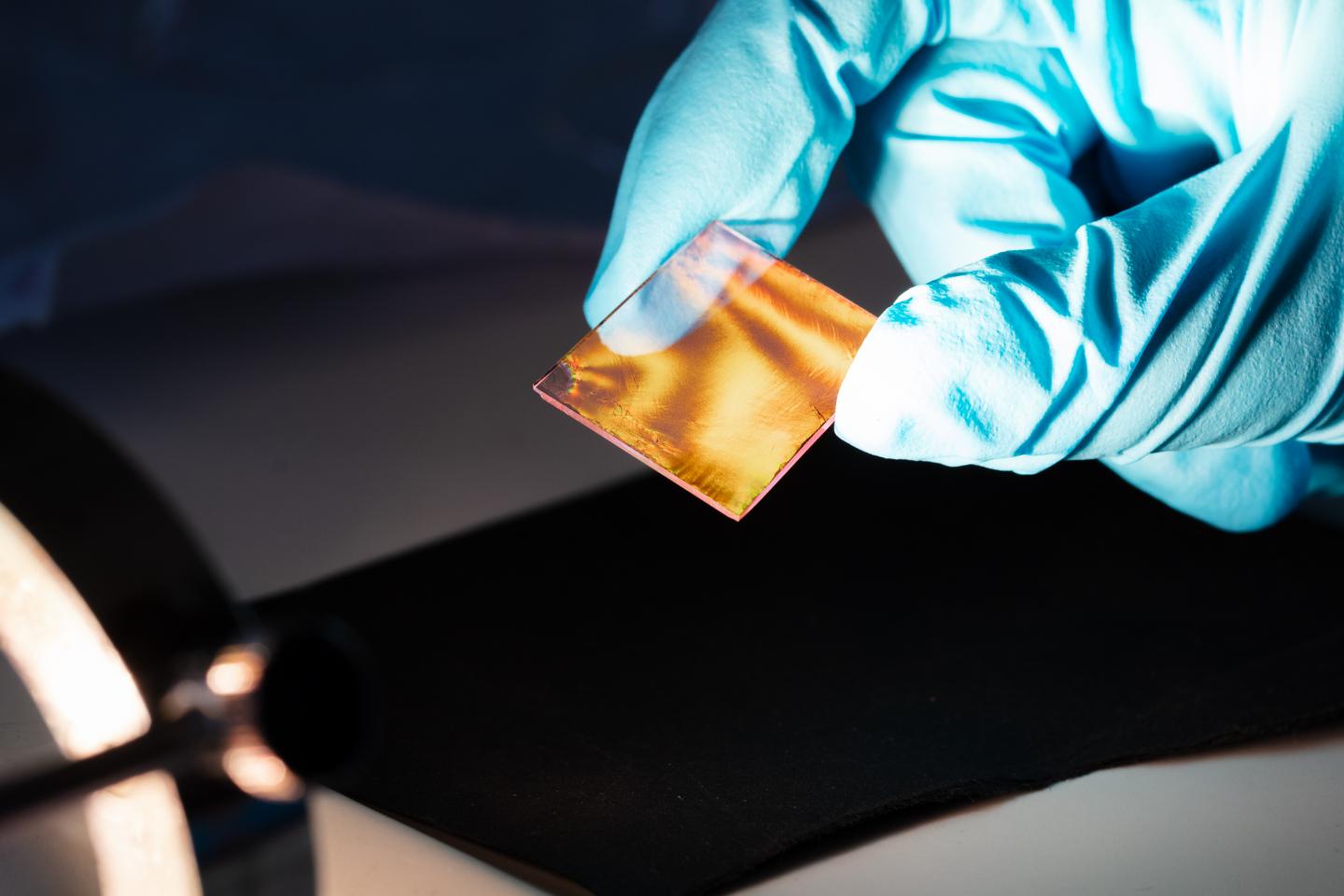

Credit: HHU / Christoph Kawan

The group “Colloids and Nanooptics” of Prof. Dr. Matthias Karg at the Institute of Physical Chemistry has come up with a simple yet precise technique for developing highly ordered particle layers. The group is using tiny, soft and deformable spherical polymer beads with a hydrogel-like structure. Hydrogels are water swollen, three-dimensional networks. For example, we are familiar with these structures as super-absorbers in babies’ nappies that have the ability to soak up large quantities of liquids.

Within these hydrogel beads are tiny gold or silver particles, just a few nanometres in size, that Karg’s team synthesizes at HHU using metal salts in a reduction process. “We can adjust the size of the gold particles very precisely, because the hydrogel shells are permeable to dissolved metal salts, allowing for successive overgrowth of the gold cores.” The structure of these core-shell particles can be roughly compared with that of a cherry, where a hard core is surrounded by soft pulp. However, the particles from the laboratory are roughly one hundred thousand times smaller.

The Duesseldorf-based researchers can then use a dilute solution of these hydrogel beads to produce thin monolayers. They apply the beads to a water surface, where a highly ordered and colourfully shimmering layer self-assembles. They transfer this layer from the water surface onto glass substrates. This transfer makes the entire glass substrate shimmer.

Looking at this layer with an electron microscope reveals a regular, hexagonally ordered particle array. “These are the gold particles in their shells,” explains doctoral student Kirsten Volk, “and we see that they are arranged in a single, highly ordered layer.” It’s the gold particles that determine the colour of the layer: They reflect visible light with certain wavelengths, which interferes and thus creates the impression of a different colour from different angles.

“These thin layers are very interesting for optoelectronics – i.e. the transfer and processing of data using light. It may also be possible to use them to build miniaturised lasers,” explains Prof. Karg. These nanolasers are only nanometres in size, thus constituting a key technology in the field of nanophotonics.

In a study now published in the journal ACS Applied Materials & Interfaces, the Duesseldorf-based researchers have overcome a major obstacle on the path to such nanolasers. They succeeded in creating collective resonances in the gold particles by incident light. This means that the gold particles are not excited individually; instead, all excited particles are in resonance. This collective resonance is the basic prerequisite for building lasers. The special aspect of the research findings published is that not only can the particle layers be created very easily and on a large scale, they are also especially thin.

For optoelectronic applications and nanolasers, the resonant modes will have to be amplified further in the thin layers. Prof. Karg: “Next we will try to amplify the resonance further by means of doping with emitters. In the long term, this could also allow us to realise electrically powered nanolasers.”

###

Original publication

Kirsten Volk, Joseph P. S. Fitzgerald, and Matthias Karg, In-Plane Surface Lattice and Higher Order Resonances in Self-Assembled Plasmonic Monolayers: From Substrate-Supported to Free-Standing Thin Films, ACS Appl. Mater. Interfaces 2019 11 (17), 16096-16106

DOI: 10.1021/acsami.9b03197

Media Contact

Arne Claussen

[email protected]

Related Journal Article

http://dx.