Epoxy resins serve as vital components in various industries, establishing themselves as indispensable coatings and adhesives in sectors ranging from construction to aerospace. Despite their widespread usage, these versatile materials pose significant challenges regarding recycling and responsible disposal. A groundbreaking study conducted by a team of researchers, including experts from the University of Tokyo, has introduced an innovative method that holds the promise of reclaiming materials from numerous epoxy products more efficiently. This achievement has been made possible through the development of a cutting-edge solid catalyst, a significant advancement in material recovery technology.

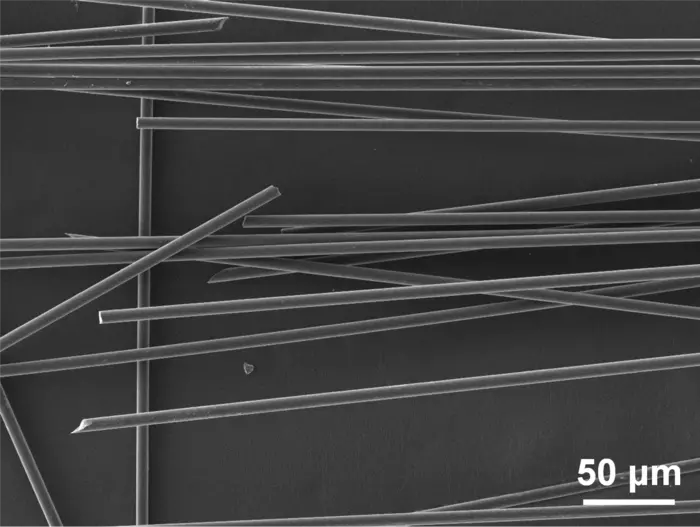

The omnipresence of epoxy compounds in everyday life is striking. Found in electronic devices due to their exceptional insulating properties, as well as in footwear where their robust binding capabilities come into play, epoxy resins are woven into the very fabric of contemporary society. In the construction sector, their physical resilience is unparalleled, making them a go-to choice for various applications. Furthermore, their incorporation into aircraft bodies and wind turbine blades exemplifies their role in supporting high-performance materials, such as carbon and glass fibers. Despite these benefits, epoxy resins are predominantly classified as plastics, presenting formidable challenges when it comes to end-of-life management.

High temperatures, exceeding 500 degrees Celsius, are often required to decompose fiber-reinforced plastics, an approach that carries considerable energy costs and risks damaging the fibers intended for recovery. The harsh conditions typically used not only consume copious amounts of energy but also pose significant environmental concerns. In light of this, a relatively new process known as catalytic hydrogenolysis has emerged as a promising alternative. However, the existing catalysts used in this method have limitations, notably their inability to be reused, as they dissolve in the solvent during the decomposition process.

The research team, led by Associate Professor Xiongjie Jin and Professor Kyoko Nozaki from the Department of Chemistry and Biotechnology at the University of Tokyo, has engineered an innovative solution—a solid bimetallic catalyst composed of nickel and palladium supported on cerium oxide. This advanced catalyst is designed to mediate reactions between epoxy resins and hydrogen gas, facilitating the decomposition process while allowing for the effective recovery of valuable materials such as carbon fibers, glass fibers, and phenolic compounds. The significance of this development lies not only in its efficiency but also in its capacity for reuse.

What sets this new catalyst apart from its predecessors is its remarkable durability; it can withstand at least five cycles of use without diminishing performance. This transformative capability opens doors to broader applications within the field of recycled plastics, suggesting potential for adapting the catalyst for use with other resin types. Effective at cleaving carbon-oxygen bonds, the catalyst’s versatility makes it a promising tool for tackling a variety of plastic waste challenges.

Though the catalytic process operates at a relatively low temperature of approximately 180 degrees Celsius, which is significantly less demanding than traditional methods, the researchers acknowledge that there is still much work to be done. Improving the environmental footprint associated with the solvents currently in use remains a priority for the team. Furthermore, a push toward finding cost-effective alternatives that do not rely on precious metals like palladium could pave the way for more accessible and sustainable recycling solutions.

In exploring the future of this research, there are numerous venues for enhancing catalytic efficiency and expanding the range of recoverable materials from diverse epoxy formulations. As the field stands on the brink of significant transformation, innovation will undoubtedly play a crucial role in shaping the landscape of material recovery technologies.

The need for advanced recycling technologies has never been more pressing given the ever-increasing reliance on synthetic materials within various industries. The introduction of efficient catalytic methods not only addresses the practical challenges of recycling but also aligns with a global initiative to reduce plastic waste and its impact on the environment. As researchers like Jin and Nozaki continue to refine their techniques, the potential for broader adoption of such methodologies may soon come to fruition.

This study unambiguously highlights the urgent need for sustainable practices in materials science and opens doors to discussions about future avenues in plastic recycling. It highlights how interdisciplinary collaboration can lead to innovative solutions capable of addressing some of today’s most pressing environmental challenges.

The engagement of institutions such as the University of Tokyo in pioneering research initiatives undoubtedly contributes to fostering an environment conducive to sustainable innovation. By bridging academia and industry, such research endeavors can inspire further advancements in the field of materials recovery, laying the groundwork for a brighter and more sustainable future.

In conclusion, the development of a robust and reusable catalyst for the recycling of epoxy resins marks a definitive step forward in addressing one of modern society’s significant challenges. As the research continues to evolve, the implications for both industry practices and environmental sustainability will be monumental, setting a precedent for future developments in the field.

Subject of Research: Recycling of epoxy resins using a bimetallic catalyst

Article Title: Bimetallic synergy in supported Ni−Pd catalyst for selective hydrogenolysis of C−O bonds in epoxy resins

News Publication Date: 6-Feb-2025

Web References: Nature Communications

References: DOI: 10.1038/s41467-025-56488-4

Image Credits: Credit: ©2025 Jin et al. CC-BY-ND

Keywords

Recycling, Epoxy Resins, Catalytic Hydrogenolysis, Bimetallic Catalyst, Sustainability, Material Recovery, Circular Economy, Environmental Impact.

Tags: advances in sustainable materialsbreakthroughs in material recovery technologychallenges of epoxy resin disposalenvironmental impact of epoxy plasticsepoxy applications in construction and aerospaceepoxy resins in everyday lifeinnovative solid catalyst for epoxy recoveryreclaiming materials from epoxy productsreducing plastic waste through recyclingresponsible disposal of industrial adhesivessustainable epoxy recycling methods