SAN ANTONIO — October 11, 2023 —Southwest Research Institute has been selected to receive a $1.5 million contract from the U.S Department of Energy to evaluate the safety and efficiency of a full-scale compressor system for hydrogen-natural gas blends containing up to 20 percent hydrogen by volume. SwRI will collaborate with the Gas Machinery Research Council (GMRC) on this project.

“Hydrogen has been recognized as a viable alternative to natural gas fuel,” said SwRI Senior Research Analyst Sarah Simons. “However, a pure hydrogen stream is not compatible with existing energy transport infrastructure because hydrogen and natural gas have different characteristics. Using a blend of hydrogen and natural gas can avoid the need to create new pipelines and other infrastructure while reducing greenhouse gas emissions.”

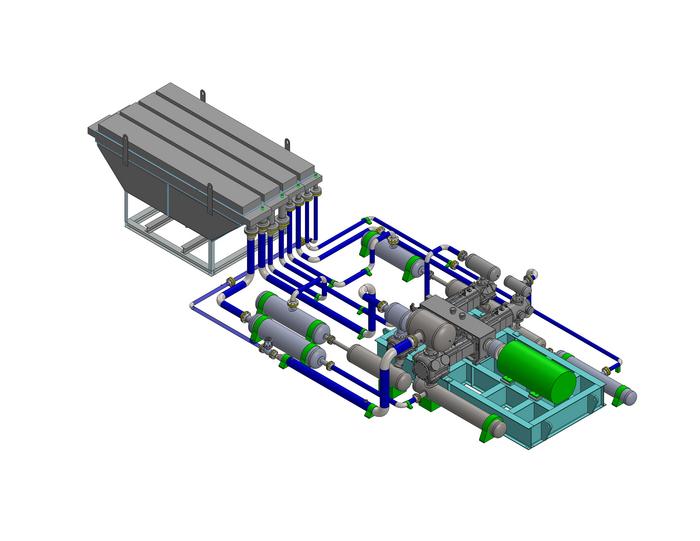

Before natural gas is delivered to homes and businesses for heating or cooking, it is pressurized by compressors to flow through gas pipelines. The SwRI-led project will utilize a full-scale reciprocating compressor loop at the Institute’s San Antonio campus to evaluate the safety and efficiency of pressurizing natural gas-hydrogen blends for pipeline transport.

“Because hydrogen molecules are so much smaller than natural gas, they can infiltrate materials resulting in embrittlement to piping and damage to infrastructure. The wide differences between hydrogen and natural gas properties can change performance characteristics and also put various piping components, such as flow control valves, at risk for failure,” Simons said. “This project will evaluate the risks to the system and components associated with each tested percentage of hydrogen and research technical solutions to enable safe, efficient compression of hydrogen-natural gas blends.”

Various compressor components have been evaluated separately for use with natural gas and hydrogen blends. SwRI will build on that foundation by studying a complete compressor system with these components installed to ensure the system as a whole can operate safely and efficiently in the same environment. The team will also measure leakage and test gas meters for accuracy and compatibility with hydrogen-natural gas blends.

SwRI will initially make minor modifications to the compressor loop, updating some components for hydrogen compatibility and upgrading capabilities for operation with a hydrogen natural gas blend. Like most reciprocating compressors, the primary machinery is already compatible with hydrogen. SwRI will design and construct a blending skid to analyze blended hydrogen in five percent increments from zero to 20 percent volume concentration and evaluate a separation system to extract the hydrogen from the process gas.

“The final task will be to take the lessons learned from this work, combine it with published research and develop a best practices document for pipeline operators to reference,” Simons said. “Appliances commonly installed in homes, such as natural gas stoves or heaters, as well as their connections to the gas pipeline, would require further evaluation to ensure they’re compatible with a hydrogen blend.”

For more information, visit https://www.swri.org/industry/advanced-power-systems/hydrogen-energy-research or https://www.swri.org/industry/station-pipeline-design-compressors-pumps/hydrogen-blending-natural-gas-pipelines.

Credit: Southwest Research Institute

SAN ANTONIO — October 11, 2023 —Southwest Research Institute has been selected to receive a $1.5 million contract from the U.S Department of Energy to evaluate the safety and efficiency of a full-scale compressor system for hydrogen-natural gas blends containing up to 20 percent hydrogen by volume. SwRI will collaborate with the Gas Machinery Research Council (GMRC) on this project.

“Hydrogen has been recognized as a viable alternative to natural gas fuel,” said SwRI Senior Research Analyst Sarah Simons. “However, a pure hydrogen stream is not compatible with existing energy transport infrastructure because hydrogen and natural gas have different characteristics. Using a blend of hydrogen and natural gas can avoid the need to create new pipelines and other infrastructure while reducing greenhouse gas emissions.”

Before natural gas is delivered to homes and businesses for heating or cooking, it is pressurized by compressors to flow through gas pipelines. The SwRI-led project will utilize a full-scale reciprocating compressor loop at the Institute’s San Antonio campus to evaluate the safety and efficiency of pressurizing natural gas-hydrogen blends for pipeline transport.

“Because hydrogen molecules are so much smaller than natural gas, they can infiltrate materials resulting in embrittlement to piping and damage to infrastructure. The wide differences between hydrogen and natural gas properties can change performance characteristics and also put various piping components, such as flow control valves, at risk for failure,” Simons said. “This project will evaluate the risks to the system and components associated with each tested percentage of hydrogen and research technical solutions to enable safe, efficient compression of hydrogen-natural gas blends.”

Various compressor components have been evaluated separately for use with natural gas and hydrogen blends. SwRI will build on that foundation by studying a complete compressor system with these components installed to ensure the system as a whole can operate safely and efficiently in the same environment. The team will also measure leakage and test gas meters for accuracy and compatibility with hydrogen-natural gas blends.

SwRI will initially make minor modifications to the compressor loop, updating some components for hydrogen compatibility and upgrading capabilities for operation with a hydrogen natural gas blend. Like most reciprocating compressors, the primary machinery is already compatible with hydrogen. SwRI will design and construct a blending skid to analyze blended hydrogen in five percent increments from zero to 20 percent volume concentration and evaluate a separation system to extract the hydrogen from the process gas.

“The final task will be to take the lessons learned from this work, combine it with published research and develop a best practices document for pipeline operators to reference,” Simons said. “Appliances commonly installed in homes, such as natural gas stoves or heaters, as well as their connections to the gas pipeline, would require further evaluation to ensure they’re compatible with a hydrogen blend.”

For more information, visit https://www.swri.org/industry/advanced-power-systems/hydrogen-energy-research or https://www.swri.org/industry/station-pipeline-design-compressors-pumps/hydrogen-blending-natural-gas-pipelines.