In a groundbreaking advance that challenges fundamental assumptions in material science, researchers from AMOLF and ARCNL have engineered structures capable of performing what they term “countersnapping” — a mechanical phenomenon wherein materials, when pulled outward, defy intuition by snapping inward, contracting suddenly rather than stretching. This counterintuitive response, now experimentally demonstrated for the first time, signals a paradigm shift in how we understand and harness mechanical instabilities. Published in the prestigious Proceedings of the National Academy of Sciences, the study details the intricate design principles behind these novel systems and envisions a new class of smart materials with transformative applications across technology sectors.

Traditional mechanical behavior dictates that when tensile force is applied to an elastic object like a rubber band, the object elongates in response. However, the countersnapping phenomenon exhibits an entirely different response: instead of elongation, the structure abruptly contracts upon being pulled, an effect that until now had been considered nearly impossible to manifest in practical systems. This astonishing behavior arises from precisely orchestrated internal instabilities, engineered through a modular design approach where simple mechanical elements are combined in sophisticated architectures.

The inception of this study hinges on the premise that mechanical systems can transcend conventional limitations by deploying designed instabilities. Bas Overvelde, lead investigator of the Soft Robotic Matter Group, emphasizes, “We have demonstrated that mechanical architectures can be intentionally constructed to exhibit paradoxical responses.” This breakthrough opens the door for devices and structures with unprecedented dynamic capabilities, effectively rewriting the rules of material mechanics and offering radically new functionalities.

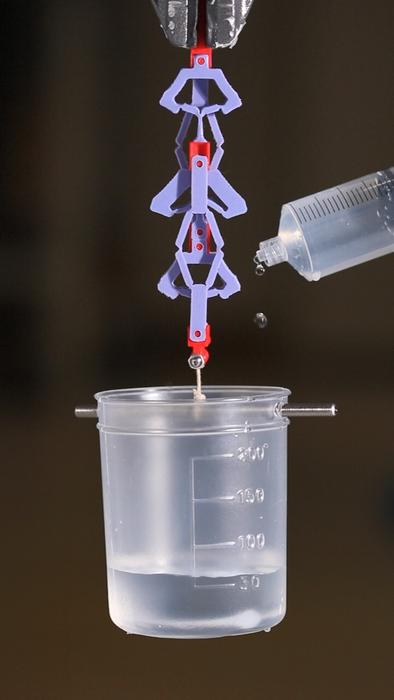

Central to achieving countersnapping is the strategic assembly of fundamental building blocks into assemblies that interact geometrically and mechanically in complex ways. Rather than attempting to fabricate a final intricate design in one step, the researchers adopted a “bottom-up” methodology, engineering simpler units exhibiting predictable behavior and then coupling these units to elicit emergent instabilities. Paul Ducarme, first author on the study, notes “It’s like discovering a new language for mechanical design — one that enables us to program and harness behaviors that would otherwise be impossible.”

This counterintuitive contraction under tension has profound implications for soft robotics. Devices that can convert pulling forces into sudden compression enable innovative propulsion methods and motion control mechanisms absent of motors or sophisticated electronics. For example, soft medical robots navigating the delicate human body could utilize one-way sliding motions facilitated by countersnapping, gaining highly controllable directional movement with remarkably low energy consumption.

Notably, the mechanical properties of these structures are not static. They can switch stiffness states on demand, providing dynamic adaptability crucial for assistive wearables such as exoskeletons or prosthetic limbs. During movement, flexibility is paramount, but at moments requiring stability or load-bearing, instantaneous stiffening is essential. Countersnapping mechanics enable this rapid transition between soft and stiff states, a feature impossible to replicate with conventional materials or actuators.

Beyond robotics and wearables, countersnapping structures exhibit intrinsic vibration damping capabilities that can revolutionize how engineers mitigate destructive oscillations. In aircraft, wind turbines, and seismically active buildings, uncontrolled vibration poses substantial risks. Materials that autonomously absorb and dampen energy without complex control systems offer safety and performance improvements. These metamaterials could dynamically adapt to varying vibration frequencies and magnitudes, enhancing resilience with minimal maintenance.

Further experimentation suggests that cascading multiple countersnapping elements can lead to metamaterials capable of information processing and decision-making, embodying the concept of mechanical computation. According to Martin van Hecke, another principal investigator, “By integrating these snapping units, materials themselves can compute, sense, and respond — essentially functioning as mechanical computers embedded in the fabric of the structure.” This insight hints at the future of materials science where the boundary between passive matter and active machines dissolves.

The implications extend far into fundamental physics as well. Traditionally, mechanical instability, such as snapping, has been viewed as a limitation or failure mode to be avoided. This research reframes instability as a powerful tool for innovation, harnessed deliberately to unlock exotic behaviors. Such control over mechanical phases enriches the design space, allowing materials that can shift between distinct, stable configurations under minimal external stimuli.

Remarkably, the countersnapping effect also informs the engineering of deployable space structures and everyday objects. Just as conventional snapping mechanisms enable pop-up tents or foldable devices, countersnapping introduces a new dimension of functional behavior — structures that react oppositely to applied forces, allowing for novel deployment and actuation strategies. This can lead to lighter, more compact systems that self-stabilize or morph on demand in extreme environments.

From the perspective of manufacturing, the modular approach facilitates scalability and customization. By tailoring simple unit cells and their interactions, designers can tune the mechanical response precisely, enabling applications from microscale biomedical devices to large-scale architectural elements. The inherent reversibility of the countersnapping transitions also promises durability and longevity under repetitive loading cycles.

Future research will likely focus on expanding the library of building blocks and integrating countersnapping mechanics with other smart material modalities such as stimuli-responsive polymers or embedded sensors. Combining these capabilities could create multi-functional materials that not only sense and adapt but also self-repair and communicate, moving toward the vision of fully autonomous, intelligent matter.

In summary, the discovery and realization of countersnapping instabilities mark a watershed moment in material science. By bridging the gap between fundamental mechanics and applied engineering, this work unlocks a spectrum of potential innovations from soft robotics and wearable technologies to resilient infrastructures and beyond. As industries increasingly demand materials that are smarter, faster, and more adaptive, countersnapping stands out as a promising cornerstone for the next generation of mechanical metamaterials.

Subject of Research: Mechanical metamaterials exhibiting countersnapping instabilities enabling paradoxical contraction upon tensile loading.

Article Title: Exotic mechanical properties enabled by countersnapping instabilities

News Publication Date: 17-Apr-2025

Web References: DOI link

Image Credits: AMOLF

Keywords

Countersnapping, mechanical metamaterials, mechanical instability, soft robotics, vibration damping, smart materials, dynamic stiffness, mechanical computation, adaptive materials, metamaterial design, mechanical phase transitions, programmable matter

Tags: AMOLF and ARCNL researchcountersnapping phenomenonengineering novel structuresexperimental demonstration of countersnappinginnovative smart materialsmechanical instabilities in materialsmodular design approach in engineeringparadigm shift in material scienceProceedings of the National Academy of Sciences publicationtensile force response in materialstransformative applications of new materialsunconventional material behavior