Laying the groundwork for designing safe materials for third-generation EVs; identification of thermal degradation mechanism of cathode materials and creation of a real-time analysis platform

Credit: Korea Institute of Science and Technology(KIST)

Smartphone display repair cost that caused so many people to cry about, it may no longer be an issue to worry about. Research team in South Korea has developed a smartphone display material that can self-heal from damages.

The Korea Institute of Science and Technology (KIST) announced that the collaborative research team led by Dr. Yong-Chae Jung, head of the center at Institute of Advanced Composites Materials, and Professor Hak-soo Han from Yonsei University (President: Seoung-Hwan Suh) was able to develop a self-healing colorless electronic material that can self-repair cracks or damaged functions occurred on the material.

Colorless polyimide (CPI) has outstanding mechanical, electrical, and chemical properties. It features transparency like glass along with strong tensile strength and does not encounter scratches even after folding hundreds of thousands of times. Thus, it is widely commercialized and used in mobile products such as foldable and flexible displays and is also popularly used throughout the overall industry such as aerospace and PV cells. As such, since CPI is a material widely used in various industries, constant efforts are made to secure durability by addressing cracks that can occur from various exposure environments and breakages caused by continuous electromagnetic waves. While several research teams attempted to address these issues by adding additives or coating a hard-protective layer on the surface, they were unable to successfully prevent damages to the underlying materials.

In order to support quick self-healing from cracks and damaged functions while maintaining the benefits of colorless polyimide, the KIST-Yonsei University collaborative research team developed a self-healing colorless polyimide by utilizing linseed oil extracted from seeds of the flax plant. Linseed oil is easily hardened at room temperature of 25 ?, hence, it is widely used as a coating material in preserving art pieces.

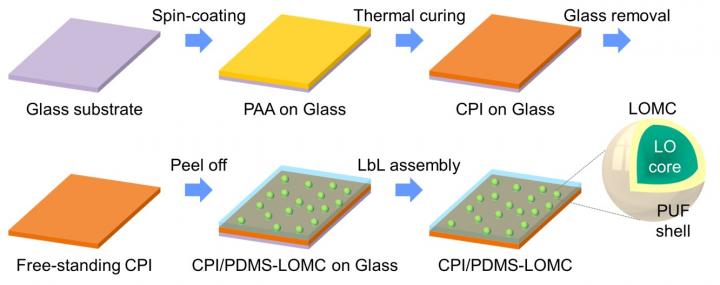

Research team at KIST fabricated linseed oil-loaded microcapsules; then, created upper-healing layers by mixing the fabricated microcapsules with silicone and coating them on colorless polyimides. In the material developed by the team, the microcapsules break when a mechanical damage occurs, then, the linseed oil leaks out and flows to the damaged area to become hardened, thereby healing the damaged area. Such self-healing capability has the advantage of being able to heal locally for local damages.

Other materials with self-repairing capabilities developed so far could only be implemented with soft materials and repaired only by applying high temperature heat to the materials. On the other hand, the material developed through this collaborative research is capable of self-healing even though it is implemented with a hard material, and it can be self-healed at room temperature without requiring high temperature heat. Additionally, it offers the advantage of accelerating healing process by reacting with humidity and UV, in turn, over 95% damage recovery has been achieved within short time of just 20 minutes.

“There is a significance in that we were able to develop a self-healing colorless polyimide that can radically solve the physical properties and lifespan of damaged polymer materials and that we presented the application range of the material, such as flexible displays and electronic material devices,” “There is a significance in that we were able to develop a self-healing colorless polyimide that can radically solve the physical properties and lifespan of damaged polymer materials and that we presented the application range of the material, such as flexible displays and electronic material devices,”

###

This study was carried out with a grant from the Ministry of Science and ICT (MSIT), as part of the Institutional R&D Program of KIST.

The findings were reported in the latest edition of the international journal, ‘Composite Part B: Engineering‘ (Top 1.67% in the field of JCR).

Media Contact

Do-Hyun Kim

[email protected]

Related Journal Article

http://dx.