Singapore, 15 November 2023 – Researchers from the Critical Analytics for Manufacturing Personalized-Medicine (CAMP) Interdisciplinary Research Group (IRG) of Singapore-MIT Alliance for Research and Technology (SMART), MIT’s research enterprise in Singapore, in collaboration with the Agency for Science, Technology and Research (A*STAR) Bioprocessing Technology Institute (BTI) and National University Health System (NUHS), have developed a groundbreaking technology capable of extracting mesenchymal stem cells (MSCs) directly from pure bone marrow – also known as bone marrow aspirate (BMA), a pivotal source of MSCs – without dilution.

Credit: SMART CAMP

- Traditional bone marrow aspirate (BMA) stem cell extraction methods are complex, time-consuming, and yield poor results due to antiquated centrifugation techniques

- SMART’s new method of isolating stem cells from BMA is simpler and ten times faster, resulting in twice as efficient enrichment of mesenchymal stem cells

- The technology also enables faster drug production in cell therapy manufacturing, while bone marrow donors benefit from shorter aspiration processes

Singapore, 15 November 2023 – Researchers from the Critical Analytics for Manufacturing Personalized-Medicine (CAMP) Interdisciplinary Research Group (IRG) of Singapore-MIT Alliance for Research and Technology (SMART), MIT’s research enterprise in Singapore, in collaboration with the Agency for Science, Technology and Research (A*STAR) Bioprocessing Technology Institute (BTI) and National University Health System (NUHS), have developed a groundbreaking technology capable of extracting mesenchymal stem cells (MSCs) directly from pure bone marrow – also known as bone marrow aspirate (BMA), a pivotal source of MSCs – without dilution.

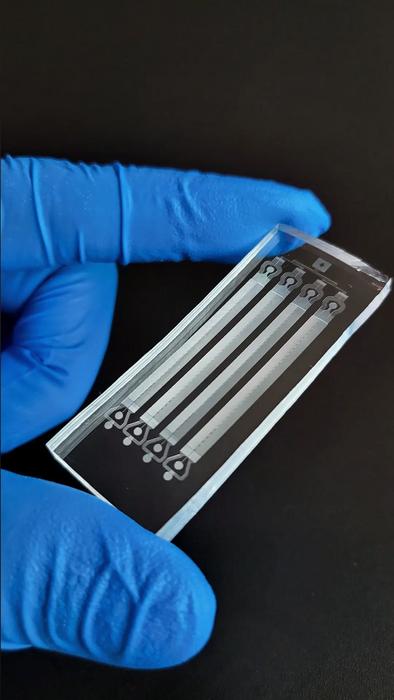

Using a world-first continuous sorting technique on a multi-chip Deterministic Lateral Displacement (DLD) microfluidic platform, the new method doubles the quantity of MSCs obtained from bone marrow samples and shortens the time taken to around 20 minutes. It also reduces donor discomfort due to less bone marrow being extracted, speeds up cell production, and simplifies cell therapy manufacturing. This advancement represents a significant step toward more accessible and efficient advanced medical treatments that use MSCs – including treatment for osteoarthritis, autoimmune and infectious diseases, and neurological disorders.

Cell therapy is a field of medicine where cells are used as living drugs to fight diseases or restore and replace damaged cells. Advances in regenerative medicine and immunotherapy have benefited countless patients; they offer numerous new treatment alternatives to previously intractable diseases, with hundreds more in the developmental pipeline that gives new hope to patients. However, obtaining high-quality raw materials – in this case, MSCs – has long been a hurdle in cell therapy manufacturing, as traditional isolation methods such as centrifugation are inefficient and complex. In addition to a long processing time of around two to three hours, current methods result in low yield due to challenges such as osmotic stress and complex workflows. State-of-the-art sorting techniques such as fluorescence-activated cell sorting (FACS) rely on costly antibodies and intricate preparation, posing major limitations for manufacturing of these living medicines.

In a paper titled “Scalable mesenchymal stem cell enrichment from bone marrow aspirate using DLD microfluidic sorting”, recently published in the journal Lab on a Chip, SMART researchers have pioneered a revolutionary stem cell sorting platform, addressing the challenges of large-scale cell sorting and manufacturing. Using DLD microfluidic technology, a label-free cell sorting method which distinguishes between stem cells and blood cells, the platform processed small bone marrow samples (2.5mL) in just 20 minutes with double the stem cell yield compared to traditional methods, and bypasses costly reagents and complex processes.

In this method pioneered by SMART, human bone marrow samples that arrive at the laboratory undergo a simple filtration step to remove unwanted cells and tissues that could obstruct the chip. Samples are then loaded onto SMART’s sorting platform, and cells of interest (MSCs) are automatically sorted and collected in outlet reservoirs. These collected cells are then combined into a vial for further processing and quantification as needed.

This innovative breakthrough in cell sorting utilises microfluidic technologies, leveraging cells’ natural properties and eliminating the necessity for labelling. With conventional methods, cells are sorted using fluorescent or magnetic tags to label certain cellular features. This is challenging as these labels could interfere with subsequent analysis and testing, or worse damage the cells. In comparison, passive techniques like the DLD method developed at SMART are user-friendly, gentle on cells and easily integrated into clinical sample processing workflows. MSCs are very sensitive to its external environment, and perturbations could alter the biology in unanticipated ways.

“This novel platform provides a fresh perspective for stem cell sorting through a more efficient, label-free and, importantly, seamless process integration into current industrial manufacturing pipeline. Our research team at SMART is excited about the possibilities this technology brings to the field of stem cell research and therapy. The successful demonstration of this technology gives us greater confidence to venture into other bioprocessing applications such as leukopheresis with great potential for clinical impact. This will significantly accelerate the development of cutting-edge treatments and improve accessibility for cell therapy,” said Mr Nicholas Tan, Research Engineer at SMART CAMP and lead author of the paper.

“Even though DLD cell sorting has previously been demonstrated, what is new in this work is that we were able to deploy the technique at a sufficiently high processing flow rate to impact real-world stem cell manufacturing workflow. Biomanufacturing and bioprocessing are areas in which I see much potential for applying microfluidics technology to improve overall efficiency and reduce the cost significantly,” said Professor Jongyoon Han, Co-Lead Principal Investigator at SMART CAMP, Professor of Biological Engineering and Electrical Engineering at MIT and corresponding author of the paper.

Future efforts will focus on refining the technology by evaluating the quality of sorted MSCs from human bone marrow samples using methods such as reverse transcription polymerase chain reaction (RT-PCR) and differentiation assays. Simultaneously, CAMP is working towards increasing sorting speed and resolution, while refining the system’s design for portability and user-friendliness, and increasing throughput to 10 ml per minute.

“Our innovative approach marks a paradigm shift in cell sorting, a key process of cell therapy. By harnessing microfluidic technologies to capitalise on cells’ intrinsic properties, we have eliminated the need for cumbersome and expensive labelling methods. It not only streamlines the sorting process but also ensures more accurate and reliable results in medical research. This breakthrough, driven by our commitment to advancing scientific frontiers, heralds a milestone in the realm of cellular studies,” said Dr Kerwin Kwek, Research Scientist at SMART CAMP and co-lead author of the paper.

The research is carried out by SMART and supported by the National Research Foundation (NRF) Singapore under its Campus for Research Excellence And Technological Enterprise (CREATE) programme. National University Hospital provided the bone marrow sample, and A*STAR BTI performed the conventional MSC isolation method which CAMP’s technology was benchmarked against.

DOI

10.1039/d3lc00379e

Method of Research

Experimental study

Subject of Research

Cells

Article Publication Date

15-Nov-2023