Most people with early-stage glaucoma don’t know they have it, even though early treatment is key to reducing vision loss. While detecting a subtle increase in eye pressure helps doctors to diagnose glaucoma, it’s challenging to monitor continuously, especially with the variety of temperatures eyes experience. Now, researchers in ACS Applied Materials & Interfaces report a prototype “smart” contact lens that measures eye pressure accurately, regardless of temperature.

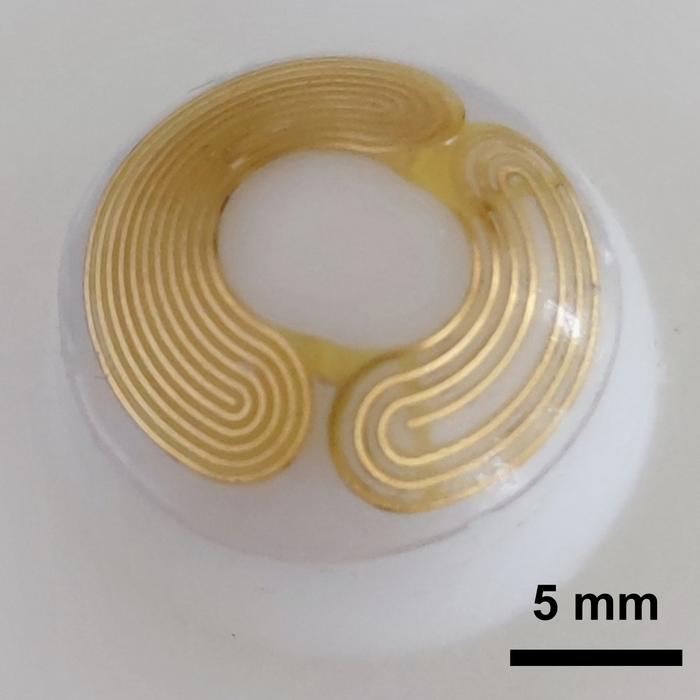

Credit: Adapted from ACS Applied Materials & Interfaces 2024, DOI: 10.1021/acsami.4c02289

Most people with early-stage glaucoma don’t know they have it, even though early treatment is key to reducing vision loss. While detecting a subtle increase in eye pressure helps doctors to diagnose glaucoma, it’s challenging to monitor continuously, especially with the variety of temperatures eyes experience. Now, researchers in ACS Applied Materials & Interfaces report a prototype “smart” contact lens that measures eye pressure accurately, regardless of temperature.

About three million people in the U.S. have glaucoma, a group of diseases that damage the optic nerve and lead to vision loss, according to the Centers for Disease Control and Prevention. Doctors use flinch-inducing “air puff tests” during eye exams to take one-time measurements of eye pressure. A slight elevation in pressure, an otherwise imperceptible symptom caused by fluid buildup around the cornea, can lead to a glaucoma diagnosis. Researchers have been testing ways to continuously and more comfortably detect these tiny fluctuations in pressure, such as contact lenses that transmit signals to receptor glasses. However, changing temperatures — like stepping outside into cold weather — can throw off the lenses’ measurements. So, Dengbao Xiao and coworkers wanted to develop a contact lens that accurately measures and wirelessly transmits real-time signals about eye pressure across a wide range of temperatures.

First, Xiao and the team designed two miniature spiral circuits, each with a unique natural vibration pattern that would change when stretched by minute amounts, such as with changes to an eye’s pressure and diameter. To create pressure-detecting contact lenses, the researchers sandwiched these tiny circuits between layers of polydimethylsiloxane, a typical contact lens material. Then they wirelessly read the embedded circuits’ vibration patterns by holding a coil near the lens that was connected to a computer. The transmitted signals were unaffected by tests meant to mimic eye movement, extended exposure to moisture (to simulate damp conditions in the eye), and daily wear and tear.

In laboratory tests, the researchers placed the new lenses on three individual pig eye specimens while controlling the ocular pressures and temperatures. The contact lenses monitored and wirelessly transmitted pressure data from 50 to 122 degrees F. When pressures were calculated from the signal of only one circuit in the lens, the results deviated up to 87% from the true values. However, when information from both circuits was used, the pressure readings differed by only 7% from the true value because the combination removed temperature-related errors. The researchers say that their dual-circuit “smart” lens design has potential to be used for accurate early detection and monitoring of glaucoma, even in a wide range of temperatures.

The authors acknowledge funding from the National Natural Science Foundation of China.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive news releases from the American Chemical Society, contact [email protected].

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.

Follow us: X, formerly Twitter | Facebook | LinkedIn | Instagram

Journal

ACS Applied Materials & Interfaces

DOI

10.1021/acsami.4c02289

Article Title

“Temperature Self-Compensating Intelligent Wireless Measuring Contact Lens for Quantitative Intraocular Pressure Monitoring”

Article Publication Date

23-Apr-2024