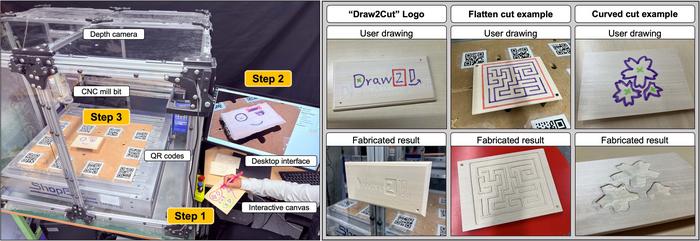

In an innovative leap for digital manufacturing, researchers from the University of Tokyo have developed a groundbreaking system named Draw2Cut, poised to simplify the interaction with computer numerical control (CNC) machines. These machines, which dominate modern fabrication processes by automating precise cutting and milling operations, often require extensive knowledge of design software and complex modeling processes. Draw2Cut offers a fresh, intuitive alternative, allowing users to directly annotate materials with simple drawings that delineate their fabrication intentions through color-coded instructions.

The context in which Draw2Cut was developed underscores a societal shift towards democratizing manufacturing. Over the years, advancements in technology have repeatedly lowered barriers to entry, enabling individuals without extensive training or resources to engage in activities once reserved for skilled professionals. Whether through the advent of 3D printing or advancements in DIY robotics, individuals are increasingly able to personalize their creations at home. Nevertheless, the operation of CNC machines has remained steeped in complexity—until now.

The central philosophy behind Draw2Cut is to meld traditional craftsmanship with cutting-edge technology. Project Assistant Professor Maria Larsson, leading the initiative, highlights the existing challenges in operating CNC milling machines, primarily the necessity of prior knowledge in computer-aided design (CAD) software. Draw2Cut was sparked by the desire to liberate users from this constraint, allowing them to intuitively mark their designs directly onto the workpiece. This innovative approach mirrors the indispensable marking techniques used by carpenters throughout history, demonstrating a fascinating blend of old-world craftsmanship with contemporary digital fabrication.

At its core, the Draw2Cut system comprises a sophisticated vision system that recognizes the user’s drawings and translates them into 3D CAD models ready for milling. Users can select from a specific palette of colors to indicate varied milling commands, turning a simple drawing into a set of instructions that the CNC machine understands. For example, purple lines indicate outlines for cutting, while red and green lines dictate how the machine should interact with the material — whether to cut straight down or create gradients. This multi-colored approach grants users the ability to communicate complex ideas with surprising simplicity.

The implementation of this system, according to Larsson, posed significant challenges, particularly regarding the establishment of a drawing language that was both intuitive and unambiguous. The need for symbols and colors to convey precise instructions—unlike traditional painting where expression can be fluid—required a rigorous systematic approach. Precise calibration of the imaging equipment was also crucial to ensure that the machine could accurately interpret the drawings, maintaining a cutting precision of approximately 1 millimeter. Such technical hurdles underscore the sophistication of the Draw2Cut system while simultaneously highlighting its potential to broaden access to CNC milling technology.

The implications of Draw2Cut go beyond simply making CNC technology more user-friendly; they touch on a grander vision of reimagining personal fabrication. By lowering the threshold for entry, the system opens doors for novice users, including children, to engage in creative projects that were previously reserved for those with specialized knowledge. Adult users, including seasoned professionals, may also find value in the system’s capacity to quickly convey ideas without navigating the complexities of traditional design software.

Looking to the future, the researchers aim to expand the capabilities of Draw2Cut to include a broader array of graphics and stroke styles. This could enable an even wider scope of creative expression, tailored to suit various user needs. Furthermore, the open-source nature of Draw2Cut provides an avenue for developers to build upon the existing platform, customizing it for diverse applications across industries.

The research team recognizes that, while Draw2Cut does not yet match the precision and craftsmanship of skilled artisans, the system’s primary objective is to broaden accessibility. It aspires not to replace human artists and artisans but to empower more people to embark on their creative journeys in digital fabrication. By harnessing basic drawing skills, individuals of all ages can now tap into their creative potential, making the world of CNC machining approachable and inviting.

Moreover, through this initiative, the University of Tokyo’s User Interface Research Group seeks to inspire future innovations in personal fabrication, showing how technology can enhance human creativity rather than stifle it. The focus on user-centric design ensures that Draw2Cut remains adaptable and relevant, responding to the evolving needs of its users.

In addition to practical applications, Draw2Cut reflects a philosophical inquiry into the relationship between humans and machines. It’s a reminder that as technology becomes more integrated into our lives, there is a need to design systems that encourage creativity and agency, allowing users to have mastery over the tools they employ. As the project continues to develop, it embodies a cultural shift towards modern manufacturing that is inclusive, innovative, and intrinsically human, reaffirming the belief that everyone should have the ability to create.

With ongoing support from various research grants and industry partnerships, the future looks bright for Draw2Cut. Each new iteration will refine its capabilities and broaden its applicability, allowing various community members to find joy and fulfillment in the creation process, ultimately fostering a new generation of makers equipped with both the technological savvy and creative mindset.

As the researchers and developers continue their commitment to expanding the Draw2Cut platform, the implications for education, personal fabrication, and DIY culture could be monumental. In a world where creativity is often hindered by technical barriers, initiatives like Draw2Cut stand at the forefront of a movement to empower individuals everywhere, merging the traditional with the avant-garde.

Subject of Research: Direct On-Material Annotations for CNC Milling

Article Title: Draw2Cut: Direct On-Material Annotations for CNC Milling

News Publication Date: April 26, 2025

Web References: University of Tokyo

References: Xinyue Gui, Ding Xia, Wang Gao, Mustafa Doga Dogan, Maria Larsson, Takeo Igarashi

Image Credits: ©2025 Igarashi et al. CC-BY-ND

Keywords

CNC milling, Draw2Cut, digital fabrication, user interface design, automation, personal creativity, manufacturing technologies.

Tags: advanced digital manufacturing solutionsbridging traditional craftsmanship and technologyCNC machine simplificationcolor-coded fabrication instructionsdemocratizing manufacturing processesdigital carpentry techniquesDraw2Cut innovationempowering non-professionals in fabricationenhancing DIY roboticsintuitive fabrication systemsreducing barriers to CNC machine operationuser-friendly design software