Researchers at the School of Science, Mae Fah Luang University, Thailand and the School of Engineering and Materials Science, Queen Mary University of London, UK have developed a shellac-based coating to improve the gas barrier properties of a recyclable, compostable and sustainably sourced packaging material to make it suitable for instant, dehydrated, frozen and chilled foods.

Credit: Prof Nattakan Soykeabkaew

Researchers at the School of Science, Mae Fah Luang University, Thailand and the School of Engineering and Materials Science, Queen Mary University of London, UK have developed a shellac-based coating to improve the gas barrier properties of a recyclable, compostable and sustainably sourced packaging material to make it suitable for instant, dehydrated, frozen and chilled foods.

Moulded pulp, made from renewable materials such as eucalyptus wood or sugarcane bagasse, is widely used as a sustainable packaging material to protect products in shipping, for food serving trays, containers and beverage carriers. Its production volume represents more than 30% of all paper-based packaging materials, and in addition to its renewable feedstocks, it is also suitable for recycling and composting.

However, the materials’ poor gas barrier properties and limited resistance to water and oil make moulded pulps unsuitable for maintaining shelf-life and quality of many products. This is typically resolved by laminating or coating the materials with petroleum-based polymers like polyethylene and a thin layer of metals, usually aluminium, making recycling or composting impractically challenging.

The aim of this study, published on 7 February in the SCI journal Polymer International, was to improve the barrier properties and surface resistance of the moulded pulp while preserving its green profile and environmental sustainability by developing a new coating based on environmentally friendly, renewable and biodegradable materials.

Shellac is derived from a resin secreted by lac bugs, and has been produced for centuries for use in products ranging from nail varnishes to furniture lacquer and various dyes. The largest producers of shellac are India, Thailand and China, but it is also produced in Bangladesh, Myanmar, Laos, Vietnam, and Mexico.

It is a biopolymer of the polyester group and widely used in the medicine and food industries due to its nontoxic nature, thermoplastic behaviour, oil resistance and good moisture barrier properties. It also exhibits good adhesion finish and can be dissolved in low-toxicity solvents. However, a coating layer of pure shellac is not commonly used because of its brittle nature and high oxygen permeability.

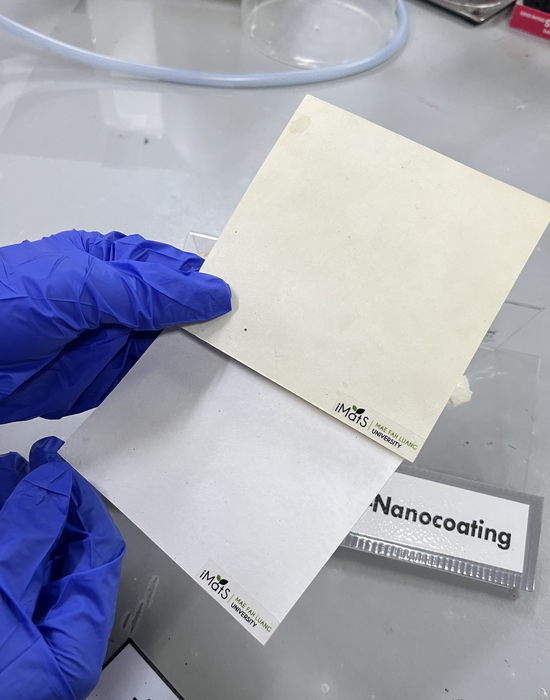

In this work, a moulded pulp was coated with a nanocomposite layer consisting of nanofibrillated cellulose (NFC) and shellac to improve its barrier and surface resistance performance. To enhance the compatibility with the shellac phase and increase the water resistance of NFC, modified nanofibrillated cellulose (mNFC) was prepared via an esterification reaction. The researchers also prepared uncoated samples and samples coated with pure shellac for comparison.

The effects of the nanocomposite coating formulation (i.e. nanocellulose content and modification), as well as different thicknesses of the coating layer on the moulded pulp, on the morphology, barrier properties (water vapour transmission rate (WVTR), OTR), water and oil resistance, thermal stability and mechanical properties of the fabricated specimens were systematically examined.

The researchers reported water vapour and oxygen transmission rates in the same range as those of conventional food packaging materials such as low-density polyethylene, oriented polypropylene, and polyethylene terephthalate.

Testing of the water contact angle, oil contact angle and oil absorption rate also indicated that the nanocomposite coating layer provided superior water resistance and a promising greaseproof surface to the moulded pulp sheet. The coating layer also enhanced the tensile properties of the sheet samples, especially for the sample coated with shellac and mNFC. The samples achieved good thermal stability (ca 250 °C) after introducing the shellac layer with lower thermal degradation temperature, confirming its practical uses for packaging applications.

Speaking to SCI, lead researcher Professor Nattakan Soykeabkaew, School of Science, Mae Fah Luang University, noted that ‘Our next aim is to develop a sustainable coating that is cheaper and scalable via materials selection and design as well as some process modifications.’

A current barrier to commercialisation lies in its cost, which Professor Soykeabkaew estimates at present be three-to-ten times more than materials currently in use. However, the coating could also ‘be applied on other eco-materials to decrease the water/moisture sensitivity’, Professor Soykeabkaew notes.

Journal

Polymer International

DOI

10.1002/pi.6469

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Sustainable nanocomposite coating for moulded pulp with enhanced barrier properties for food packaging applications

Article Publication Date

7-Feb-2023