Credit: ©Science China Press

By virtue of the unique onion-like boron nitride (oBN) precursor, nanotwinned cubic boron nitride (nt-cBN) has been successfully synthesized under high temperature and high pressure, and displays remarkable Vickers hardness up to 108 GPa (as hard as natural diamond crystal), fracture toughness to 12.7 MPa m1/2 (3-4 times of commercial single-crystal cBN), and oxidization temperature to ~1,294°C (~200°C higher than single-crystal cBN). With the same procedure, nanotwinned diamond (nt-diamond) with unprecedented hardness–two times higher than that of single crystal diamond–has also been synthesized via compressing onion carbon. The key to synthesis of nt-cBN and nt-diamond lies in the unique nanostructure of onion-like precursor. However, there is a lack of deep understanding about the effects of size and microstructure of onion-like precursors on the synthesis and properties of the emergent, technologically important nt-cBN/nt-diamond materials.

Recently, Prof. Zhisheng Zhao’s research group from Yanshan University, China traced the effects of size and microstructure of onion-like precursors on the synthesis and properties of the emergent, technologically important nt-cBN/nt-diamond materials and revealed that the size change of onion-like precursor results in the distinct microstructures, leading to significant alteration of microstructure and performance in the produced cBN nanopolycrystalline blocks. The study was addressed in SCIENCE CHINA Materials (DOI: 10.1007/s40843-019-9409-1).

Prof. Zhisheng Zhao stated: “The microstructures of high-pressure quenched materials are highly dependent on the initial precursors, pressure, and temperature conditions as well as the compression history, which are determined by both kinetics and thermodynamics factors. So, the size effect of precursor is important, e.g., TiO2 anatase nanocrystals would exhibit strong size-dependent phase selectivity at high pressure. This effect seems straightforward but the intrinsic mechanisms are distinct for different material systems.”

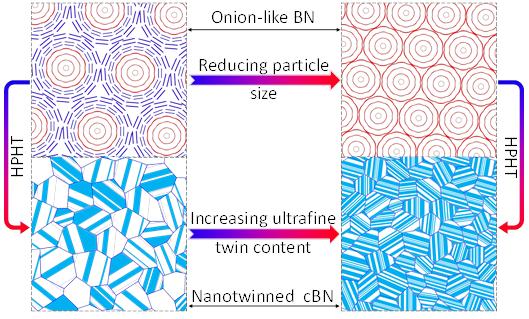

They systematically studied the influence of nanoparticle size of precursor on mechanical properties of final products. The onion-like BN (oBN) precursors with different nanoparticle sizes were prepared by centrifugal screening, and then subjected to pressure at appropriate synthesis condition to obtain nanopolycrystalline cBN. Accompanied by the size decrease of precursor from ~320 to 90 nm, the Vickers hardness of nanostructured products improved from 61 to 108 GPa. The experimental data indicated that large oBN nanoparticles possessed more flattened, orderly and graphite-like shell layers, in sharp contrast to the highly wrinkled and imperfect layers in small-diameter nanoparticles, thus resulting in the apparent reduction of ultrafine-twin substructure in synthetic products. Only the small oBN precursors with highly defective and curved layers can produce more complete nt-cBN with ubiquitous ultrafine subtwins in nanograins. The current investigation reveals that the size change of oBN precursors results in the microstructure difference of precursors, which is unusual in nanomaterials. Then, the use of this kind of distinct precursors leads to significant change in microstructure and performance of the produced nanopolycrystalline cBN bulk materials. The mechanical properties of nt-cBN are expected to be further improved by using finer oBN precursors through developing appropriate separation and screening technologies.

“Theoretically, the hardness of nt-cBN with entire ultrafine-twin microstructure can reach as high as 200 GPa, i.e., twice the hardness of natural diamond crystal, if the twin thickness is reduced to 2 nm.” says Prof. Zhisheng Zhao. “Our findings demonstrated the fundamental condition of precursor to synthesize the high-performance nt-cBN/nt-diamond materials and presented the feasible route to obtain better nt-cBN/nt-diamond through further reduction of the size of onion-like precursors.”

###

This research was funded by the National Natural Science Foundation of China (Grant Nos. 51472213, 51332005, 51572235, 51722209, and 51525205), the National Key R&D Program of China, 100 Talents Plan of Hebei Province (Grants No. E2016100013), the Natural Science Foundation for Distinguished Young Scholars of Hebei Province of China (Grants No. E2018203349), the Key R&D Program of Hebei Province of China (Grant No. 17211110D), and China Postdoctoral Science Foundation (Grant No. 2017M620097).

See the article: Kun Luo, Yang Zhang, Dongli Yu, Baozhong Li, Wentao Hu, Yong Liu, Yufei Gao, Bin Wen, Anmin Nie, Zhisheng Zhao, Bo Xu, Xiang-Feng Zhou, Yongjun Tian and Julong He, “Small onion-like BN leads to ultrafine-twinned cubic BN”, Science China Materials. doi: 10.1007/s40843-019-9409-1

Media Contact

YAN Bei

[email protected]

Related Journal Article

http://dx.