In a groundbreaking advance that blends materials science with cutting-edge machine learning, researchers at North Carolina State University have pioneered an innovative method to fabricate ultra-stretchable superomniphobic surfaces using laser ablation. This novel approach represents a significant leap forward, enabling the production of materials that repel virtually all liquids — ranging from water to aggressive acids and organic solvents — while maintaining their extraordinary properties even after being stretched up to five times their original length and enduring over 5,000 stretching cycles. The implications for this tech span soft robotics, wearable electronics, and biomedical devices, heralding a new era of resilient, multifunctional materials.

Superomniphobic surfaces are characterized by their extreme repellency to a wide spectrum of liquids, far surpassing the hydrophobic surfaces commonly encountered. Traditionally, achieving such omniphobicity involves applying specialized spray coatings embedded with nanoparticles, which craft microscopically rough textures essential for liquid repellency. However, this spray coating technique has a critical drawback: when the material beneath is stretched beyond 100% of its initial dimension, these coatings tend to delaminate and lose their protective characteristics. This limitation has stymied attempts to leverage these surfaces in applications requiring flexibility and durability.

The research team, led by Arun Kumar Kota, associate professor of mechanical and aerospace engineering, had previously addressed this shortfall by introducing microprotrusions—tiny pillars ranging between 10 to 100 microns in width—onto the substrate’s surface. By applying spray coatings atop these micro-scale pillars rather than a flat surface, they ensured the coating would remain intact atop the protrusions, even while the material stretches substantially. This ingenious design mimics a simple but telling analogy: when a person stretches their outstretched arms, their hair, akin to the microprotrusions, remains largely unaffected by the strain, preserving integrity amidst deformation.

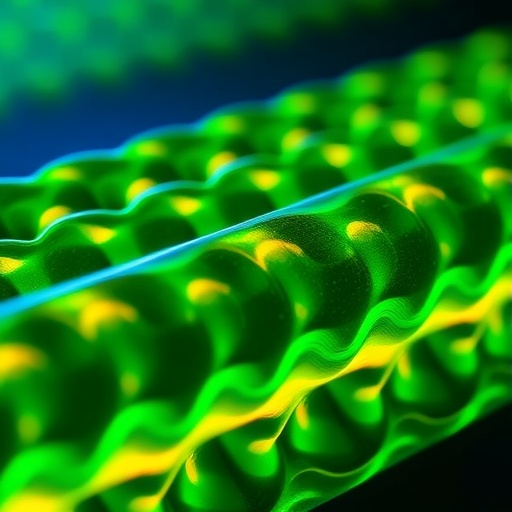

In their latest breakthrough, the research team transcended reliance on spray coatings altogether by harnessing a powerful and environmentally friendlier technique—laser ablation. This solvent-free process employs a CO2 laser to directly sculpt the surface of a siloxane elastomer, a stretchable polymer, simultaneously creating the microprotrusions and the nanoscale roughness critical to achieving superomniphobic performance. The elastomer was chemically modified with a fluorocarbon silane to enhance its intrinsic hydrophobicity, working synergistically with the laser-textured surface to repel diverse liquids.

A key hurdle in optimizing the laser ablation technique lies in the vast parameter space that governs the quality and properties of the treated surfaces. Laser power, scanning speed, and spatial pulse frequency—i.e., the number of laser pulses per unit length—all influence the resultant texture and thus the liquid repellency. The traditional approach of exploring this high-dimensional parameter space via trial and error would be prohibitively time-consuming and expensive. To surmount this, the team integrated a machine learning framework that assimilated these laser parameters alongside target surface properties, such as the sliding angle—the ease with which a liquid droplet can roll off the surface—to predict optimal laser ablation settings for superomniphobicity.

This marriage of experimental materials science with data-driven machine learning yielded a platform that rapidly iterates and predicts the best fabrication conditions. The resultant surfaces not only exhibited remarkable liquid repellency but also demonstrated resilience to extreme mechanical deformation. Even when stretched to 400% (four times their original length) and subjected to over 5,000 stretch-release cycles, these laser-ablated substrates retained their superomniphobic properties, including low contact and sliding angles across a broad spectrum of liquids. Beyond tensile strain, the surfaces maintained their functionality under twisting and folding, characteristics vital for next-generation wearable devices.

Further investigations encompassed a detailed theoretical and experimental study of how deformation affects critical surface properties. Contact angles, which measure a liquid’s wettability, breakthrough pressures necessary for liquids to penetrate the surface, and sliding angles were systematically analyzed. These studies confirmed the robustness of the laser-textured surfaces: elongation changes could be tolerated without compromising the functional repellent barrier, suggesting immense promise for dynamic environments where materials undergo repetitive, multidirectional strains.

Importantly, this laser ablation approach eliminates the use of toxic chemical solvents typically involved in spray coating processes, positioning the technique as a greener and more sustainable alternative. The precision and repeatability afforded by machine learning-guided laser structuring open the door not only to high-performance wearable electronics and artificial skin but also to protective textile dressings designed for chemically harsh or corrosive environments, a valuable asset in medical and industrial fields.

This convergence of laser fabrication and artificial intelligence resolution harnesses the power of automation to accelerate innovation in the material sciences. The platform allows researchers to circumvent the “trial-and-error” bottleneck, cutting down experimentation time by orders of magnitude while intelligently navigating complex parameter landscapes. Such an approach not only streamlines development but also lays a blueprint for future advanced materials manufactured with high precision and adaptive functionality.

The research appears in the prestigious journal Matter, marking a milestone in superomniphobic surface engineering. Supported by agencies including the National Science Foundation and the National Institutes of Health, this work is spearheaded by Mohammad Javad Zarei, a former Ph.D. student, with contributions from NC State postdoctoral researchers and faculty focused on the intersection of mechanical engineering, surface chemistry, and computational learning algorithms.

Given the rapidly evolving landscape of soft robotics, wearable healthcare monitors, and flexible electronics, the ability to produce stretchable omniphobic materials stands to revolutionize device longevity and operational environments. This advancement also opens intriguing avenues in fundamental research of surface physics under strain, inspiring future innovations that could extend to self-cleaning surfaces, anti-fouling coatings, and beyond.

In summary, through the ingenious combination of laser ablation and machine learning, researchers have unlocked a new class of ultra-stretchable superomniphobic materials that break previous limits of mechanical endurance and liquid repellency. This paradigm-shifting work propels the field toward environmentally sustainable, scalable production methods, setting a new benchmark for materials that seamlessly endure complex mechanical and chemical challenges.

Subject of Research: Not applicable

Article Title: Ultra-Stretchable Superomniphobic Surfaces via Machine Learning guided Laser Ablation

News Publication Date: February 16, 2026

Web References:

– Matter article: https://www.cell.com/matter/abstract/S2590-2385(25)00653-8

– DOI: http://dx.doi.org/10.1016/j.matt.2025.102610

References:

– Mohammad Javad Zarei et al., “Ultra-stretchable superomniphobic surfaces via machine-learning-guided laser ablation,” Matter, 2026.

Image Credits: Not provided

Keywords

Superomniphobic surfaces, laser ablation, machine learning, stretchable materials, siloxane elastomer, surface engineering, liquid repellency, soft robotics, wearable electronics, surface texture, fluorocarbon silane, sustainable fabrication

Tags: applications of superomniphobic materialsbiomedical device material advancementsflexible superomniphobic coatingshigh-cycle stretchable materialslaser ablation fabrication techniquesmachine learning in materials sciencenanoparticle-free liquid-repellent surfacessoft robotics material innovationstretchable liquid-repellent surfacessuperomniphobic surfaces durabilityultra-stretchable superomniphobic materialswearable electronics with liquid repellency