A recent announcement in the field of materials engineering emphasizes the important role that mixing intensification plays in the manufacturing of advanced materials. This significant study, which features contributions from prominent researchers like Chao Yang and Guang-Wen Chu, delves into innovative mixing methodologies targeting the inefficiencies of traditional chemical reactors. The work, guided by Jian-Feng Chen, sheds light on how cutting-edge mixing techniques can push the boundaries of industrial production, offering a promising outlook for future advancements.

Mixing is an inherent and critical component of chemical processes, fundamentally impacting the efficiency of reactions and the selectivity of the final products. When we dissect the mixing process, it can be categorized into two main types: macromixing and micromixing. Macromixing operates at the reactor scale and is responsible for the bulk distribution of materials, while micromixing unfolds at the molecular scale, affecting rapid reaction dynamics. The challenge, however, lies in quantifying these relationships, particularly in establishing a clear quantitative linkage between effective mixing and improved reaction efficiency.

In examining multi-phase mixing, the reliance on accurate experimental measurements is paramount. Advancements in measurement techniques, such as telecentric photography and high-speed imaging, have significantly enhanced our understanding of multiphase flow phenomena. One of the noteworthy methodologies, the chemical probe technique, allows for convenient assessments of mixing performance. The advent of artificial intelligence (AI) integration into traditional measurement techniques holds substantial promise, improving interpretative data analysis while simultaneously overcoming challenges, such as data dependency, that persist in this domain.

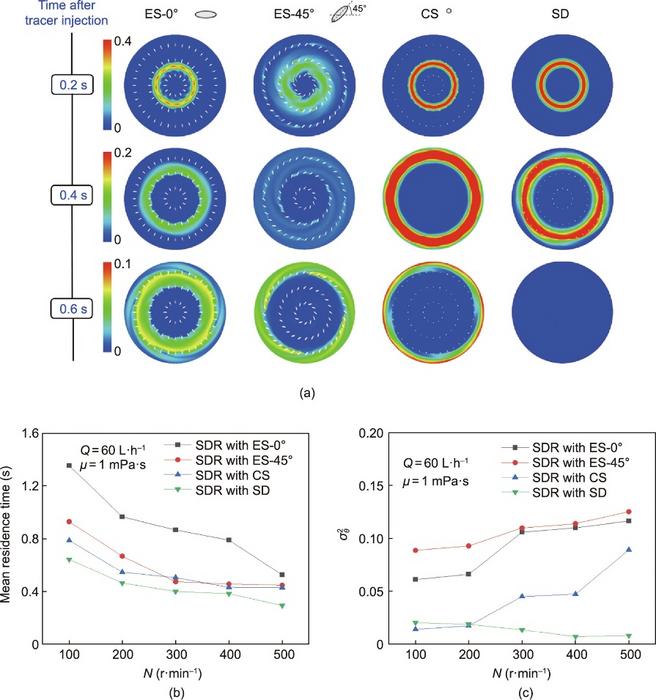

The literature devoted to macromixing and micromixing suggests a wealth of ongoing research. Traditional tracer experiments and computational fluid dynamics (CFD) simulations are frequently utilized to investigate macromixing phenomena. These simulations, especially, provide crucial insights into the behavior of mixing in reactors characterized by short residence times, a common operational challenge. As for micromixing, its influence on fast competitive reactions cannot be overstated, and it is typically assessed indirectly through micromixing time. This subtlety in measurement has spurred the development of various chemical reaction systems designed to evaluate micromixing efficiency, leading to the proposal of numerous models—both empirical and mechanistic—in the quest to articulate the intricacies of micromixing.

Promising applications have emerged from the principles of mixing intensification in various industries. For example, in the rapidly evolving lithium battery sector, researchers have successfully developed an advanced multiphase CFD-micromixing-population balance equation model for ternary precursor co-precipitation reaction crystallizers. This innovative integration allows for the digital scaling of reactors, facilitating the production of high-quality industrial precursors that bolster the burgeoning lithium battery market in China.

Equally fascinating is the utilization of high-gravity technology in optical materials manufacturing. The deployment of rotating packed-bed (RPB) reactors demonstrates a profound capability to achieve homogeneous micromixing conditions. This has been crucial in the creation of nanocomposites that exhibit precisely tunable optical properties, a significant advantage in the production of advanced optical materials. Furthermore, the agricultural industry has not been left behind; RPB reactors have shown their effectiveness in producing hollow silica nanoparticles, which serve as carriers for smart pesticide delivery systems, overcoming the longstanding challenge of scalable nanopesticide production for enhanced agricultural efficiency.

As this field of study continues to evolve, researchers have outlined a series of forward-looking research directions. These include a deeper exploration of advanced mixing technologies, such as ultrasonic and electric-field mixing, which present the potential for revolutionary impacts on mixing efficiency. Moreover, the call for the implementation of multiscale simulation techniques reflects the need for comprehensive understanding across varied systems, ensuring advancements are not siloed but integrated into a broader context. Such multidisciplinary collaborations are essential to bridge the gap between theoretical insights and practical applications, accelerating the transition from laboratory research to real-world industrial applications.

Overall, this exploration into mixing intensification underscores the intricate relationship between innovative mixing techniques and enhanced industrial capabilities. It serves as an essential compendium for both scholars in the realm of materials engineering and practitioners in various fields seeking to leverage these advances to optimize production and quality. The findings not only contribute to the scientific discourse surrounding material manufacturing but also herald a new era of efficiency that may redefine industry norms and expectations in the years to come.

The paper titled “Mixing Intensification for Advanced Materials Manufacturing” authored by Chao Yang, Guang-Wen Chu, Xin Feng, Yan-Bin Li, Jie Chen, Dan Wang, Xiaoxia Duan, and Jian-Feng Chen stands as a testament to the collaborative effort toward understanding and improving mixing processes. It promises an insightful journey into the future of materials engineering, revealing not just the technical challenges faced but also the innovative solutions that are being devised to overcome them.

Subject of Research: Mixing Intensification for Advanced Materials Manufacturing

Article Title: Mixing Intensification for Advanced Materials Manufacturing

News Publication Date: 27-Dec-2024

Web References: https://doi.org/10.1016/j.eng.2024.12.019

References: Chao Yang, Guang-Wen Chu, Xin Feng, Yan-Bin Li, Jie Chen, Dan Wang, Xiaoxia Duan, Jian-Feng Chen.

Image Credits: Credit: Chao Yang et al.

Keywords

Materials engineering, Manufacturing, Advanced materials, Mixing technologies, Chemical reactors, Lithium batteries, Optical materials, Agricultural efficiency.

Tags: advanced materials manufacturingexperimental measurement advancementsfuture advancements in materials sciencehigh-speed imaging in chemical processesimpact of mixing on reaction efficiencyinnovative mixing methodologiesmacromixing versus micromixingmixing intensification techniquesmulti-phase mixing challengesresearchers in materials engineeringtelecentric photography in mixingtraditional chemical reactors inefficiencies