Researchers at Rice University, under the leadership of Yong Lin Kong, have engineered a pioneering metamaterial characterized by its remarkable softness and strength, which can be controlled from a distance to swiftly alter its size and shape. This groundbreaking research, published in the esteemed journal Science Advances, stands as a substantial leap forward in the realms of biomedical applications, particularly for ingestible and implantable medical devices, with possibilities that could redefine the future of patient care.

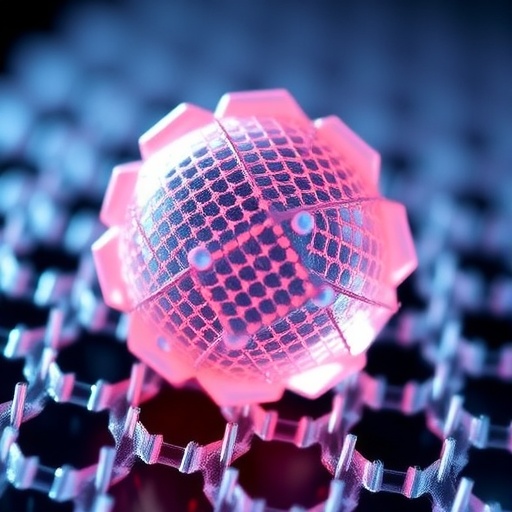

Metamaterials are engineered materials that possess unique properties not typically found in natural substances. Unlike conventional materials where behavior is primarily dictated by their chemical composition, metamaterials exhibit performance characteristics that are largely influenced by their physical structure. The specific design, shape, arrangement, and size of their microscopic components play a crucial role in determining how they respond to external stimuli, enabling functionalities that go beyond those supportable by traditional materials.

The metamaterial created by Kong and his research team combines exceptional stability with a level of deformability rarely seen in soft structures. According to the researchers, this feat of engineering is unprecedented, as the metamaterial not only displays remarkable strength—able to withstand compressive loads exceeding ten times its own weight—but also performs admirably under extreme conditions, such as temperatures well beyond typical physiological ranges and in harsh chemical environments.

In the design process, the team successfully integrated a phenomenon known as multistability into the structure of the metamaterial. Multistability refers to the ability to exist in multiple stable states simultaneously. By incorporating geometric features like trapezoidal support segments and reinforced beams, Kong’s team created energy barriers that effectively lock the material into its new shape even after the external actuation force has been removed. This significant characteristic enables the metamaterial to maintain its form and function without continuous energy application, thus presenting novel opportunities for its use in medical devices subjected to varying conditions within the body.

The soft architecture of the metamaterial addresses critical medical safety issues, notably the complications associated with conventional implantable and ingestible devices. Rigid components typically pose risks such as gastric ulcers, puncture wounds, and other inflammatory conditions. The innovative design of this new metamaterial alleviates such concerns, paving the way for safer medical interventions that minimize the occurrence of adverse reactions when devices are housed within the human body.

Utilizing cutting-edge 3D printing technology, Kong and his team crafted intricate molds that form interconnected microarchitectures consisting of tilted beams and supporting elements. This innovative design allows the metamaterial to switch rapidly between open and closed configurations (referred to as “off” and “on” states), ensuring that the transformed shape is sustained even after magnetization is withdrawn. The aggregation of numerous unit cells as structural “building blocks” results in a three-dimensional construct capable of not only changing shape but also generating complicated peristaltic motions. This attribute enables the metamaterial to propel and channel fluids in a controlled manner when influenced by a magnetic field.

Notably, the metamaterial’s performance remains steadfast even after prolonged exposure to mechanical stress and acidic environments, emulating the adverse conditions that devices face within the human stomach. Such resilience is crucial for the reliability of ingestible and implantable devices, signaling a significant advancement in materials science that can cater to the unique requirements of biomedical applications.

Kong, who holds the position of assistant professor of mechanical engineering at Rice’s George R. Brown School of Engineering, emphasizes the transformative implications of their work. “The metamaterial allows for remote control over the size and shape of devices within the body,” he stated, highlighting its potential to revolutionize medical practices. “This may one day enable targeted drug delivery, control over device locations, or induce mechanical forces deep inside the body when necessary.”

Looking ahead, the research team is currently applying the principles of this metamaterial to create ingestible systems aimed at addressing significant health issues, such as obesity in humans, or enhancing the well-being of marine mammals. Furthermore, Kong and his group are collaborating with surgical experts at the Texas Medical Center to design sophisticated wireless fluidic control systems that seek to fulfill previously unmet clinical needs.

The implications of this research extend far beyond the laboratory. By exploring the intersection of materials science, engineering, and medicine, Kong and his team are positioned at the forefront of innovation. As their metamaterial advances toward practical applications, the potential for impactful healthcare solutions grows, ushering in a new era where the physical characteristics of devices can be dynamically controlled to meet patient needs more effectively.

The first author of the study, Taylor Greenwood, was Kong’s first graduate student and has since graduated to begin a faculty position at Brigham Young University. The collaborative effort also included contributions from fellow graduate students Brian Elder and Jared Anklam, alongside postdoctoral researchers Jian Teng and Saebom Lee. This ambitious study has received backing from notable institutions, including the National Institutes of Health and the Office of Naval Research, underlining the research’s significance in advancing scientific knowledge and its potential applications in medicine.

In conclusion, this innovative work at Rice University signifies more than just a technical achievement. It fosters hope for future medical technologies that are tailored to be safer, more efficient, and responsive to the complex demands of human anatomy. The journey from theoretical material science to practical application in healthcare has made a considerable leap, showcasing the boundless possibilities that lie ahead in this exciting field of research.

Subject of Research: Metamaterials with Remote Control Capabilities

Article Title: Soft multistable magnetic-responsive metamaterials

News Publication Date: 16-Jul-2025

Web References: DOI

References: Science Advances Article

Image Credits: Jorge Vidal/Rice University

Keywords

Metamaterials, Soft Materials, Biomedical Engineering, Remote-Control Systems, 3D Printing, Multistability, Medical Devices, Mechanical Engineering.

Tags: deformable medical devicesengineered materials for patient carefuture of medical device engineeringimplantable medical device innovationsingestible device technology advancementsmetamaterials in biomedical applicationsremote-controlled metamaterialsRice University metamaterial researchsoft and strong metamaterialstransformative healthcare technologiesunique properties of metamaterialsYong Lin Kong research team