Researchers from Japan and China have recently made considerable strides in cardiovascular treatments by developing a pioneering type of vascular stent that leverages an innovative manufacturing process known as 4D printing. This new generation of adaptive vascular stents is designed to expand naturally at body temperature, offering promise for significantly safer and less invasive deployment procedures. Traditionally, vascular stents—small tube-like devices used to treat narrowed or blocked blood vessels—have required complex and invasive techniques for their placement within the human body. The need for innovative solutions in this realm has become more pressing due to the growing prevalence of cardiovascular diseases worldwide.

With cardiovascular conditions leading to critical health complications such as strokes and coronary artery diseases, the focus on creating more effective treatments is paramount. The development of the new 4D-printed vascular stent responds to this urgency. Rather than relying on external heating mechanisms to activate its deployment, this stent automatically expands at physiological temperatures, which could ultimately lead to reduced complication rates and faster recovery times for patients.

The research team, driven by Professor Shinjiro Umezu from Waseda University, consists of an interdisciplinary group of experts from various prestigious institutions across both Japan and China. The collaboration showcases a comprehensive approach, integrating skills from mechanical engineering to biomedical science, all aimed at fostering innovations in vascular treatment technologies. Included in the team are skilled researchers from Southeast University, South China University of Technology, and The University of Tokyo, indicating a robust partnership across borders.

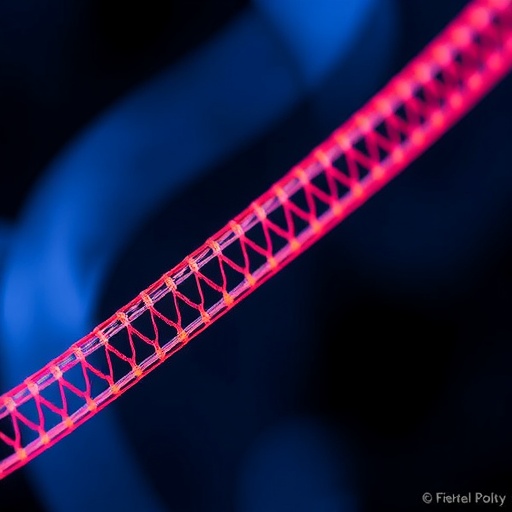

What sets these stents apart from their predecessors lies in the unique material used for their fabrication. The team utilized a polycaprolactone-based shape-memory polymer composite that is particularly favorable in the context of medical implants. By employing advanced projection micro-stereolithography 4D printing technology, the researchers were able to create highly detailed micro-architected structures. This method not only ensures precision but also opens avenues for enhanced customization to cater to individual patient needs, a critical factor in medical device efficacy.

During the manufacturing process, the scientists were able to finely modulate the thermal transition temperature of the stents to around 37 degrees Celsius, using diethyl phthalate as a plasticizer. This significant manipulation enables the device to achieve a quick and reliable shape recovery without additional thermal equipment, making the implantation process more streamlined.

Rigorous testing was carried out to assess the mechanical properties and biological compatibility of the newly developed stents. Finite element simulations demonstrated optimal mechanical flexibility alongside adequate radial strength—characteristics essential for the stent to function effectively within the dynamic environment of human blood vessels. Tests utilizing human umbilical cells revealed excellent cytocompatibility, indicating that the new stents are well-tolerated by the body.

In vivo studies were conducted on murine models, further solidifying the potential for practical clinical applications. The outcomes suggest that these vascular stents are not only effective in laboratory settings but also show promising results in actual biological environments. Professor Umezu emphasizes the transformative potential of this new technology, noting that such developments could revolutionize the way cardiovascular treatments are approached, leading to more personalized and less invasive methodologies.

As the research team articulates, this development is not merely a technological achievement; it represents a paradigm shift in the clinical application of stents. The concept of adaptive vascular stenting with programmable mechanics allows for a new level of interaction between medical devices and the human body, paving the way for future innovations not just in vascular treatment but also in the broader field of implantable medical devices.

This important breakthrough could act as a catalyst in addressing existing challenges within the realm of vascular surgeries. With key advantages, including the potential to lower the required complications during procedures and enhance patient comfort, the new stents signal a forward-thinking approach to medical engineering. These devices might not only simplify the deployment process but also reduce the dependency on various surgical tools that can complicate these procedures.

Moreover, the implications of this research extend beyond cardiovascular treatments. The methodology developed could very well be adapted for other types of implantable devices that also need to interact seamlessly with the body’s natural environment, driving future research in the field of biofabrication and regenerative medicine.

This innovative work not only highlights the potential for increased operational feasibility but also emphasizes the engineering controllability necessary for the fabrication of patient-specific stents. As personalized medicine gains traction, the continuing refinement and adaptation of such medical technologies present profound opportunities to tackle an increasing array of health complications that affect millions globally. The researchers aim to make our healthcare approaches not just smarter, but more responsive to the diverse and evolving needs of patients, particularly those inhabiting the intricate landscape of vascular health.

The research findings offer hope not only for innovation in vascular stent technology but also embody a broader vision for the future of medical devices tailored to individual patients’ anatomical and physiological conditions. As the study results indicate, the landscape of cardiovascular treatment is on the brink of transformation, promising safer and more efficient care pathways for patients worldwide.

Subject of Research: Vascular Stents

Article Title: Adaptive 4D-Printed Vascular Stents with Low-Temperature-Activated and Intelligent Deployment

News Publication Date: January 15, 2026

Web References: Advanced Functional Materials DOI

References: None available

Image Credits: Credit Professor Shinjiro Umezu from Waseda University, Japan

Keywords

Cardiovascular disease, Bioengineering, Biomedical engineering, Regenerative medicine, Additive manufacturing, Polymers, Medical technology.

Tags: 4D printed vascular stentsadaptive medical devicesadvancements in stent manufacturing processescardiovascular disease treatmentshealth complications from cardiovascular conditionsinnovative stent deployment techniquesinterdisciplinary research in medicinelow-temperature activation stentsminimally invasive cardiovascular solutionssafer vascular interventionssmart stent technologytemperature-responsive stents