A revolutionary stride has been made in the realm of materials science with the advent of an automated high-throughput system developed by a research team at the National Institute for Materials Science (NIMS) in Japan. This cutting-edge system is designed to generate extensive datasets from a single sample of a superalloy, which is extensively utilized in the aerospace sector, particularly within aircraft engines. In a mere span of 13 days, the automated system successfully produced a comprehensive experimental dataset consisting of several thousand entries. Each of these entries encapsulates intricate details regarding the interrelation of processing conditions, microstructural attributes, and resultant yield strengths, collectively referred to as “Process–Structure–Property datasets.”

The significance of this achievement cannot be overstated. Traditional methodologies for generating such extensive datasets are notoriously laborious and time-consuming, often requiring years, and in some cases, decades of consistent experimental efforts. By contrast, the newly developed automated system has demonstrated a capability to expedite this process over two hundred times faster than conventional approaches. Such efficiency holds immense potential for ushering in a new era of data-driven materials design, which is critical for advancing innovations in the field.

The establishment of high-precision experimental data is of paramount importance in materials science, serving as the bedrock for exploring material mechanisms, developing theoretical frameworks, constructing predictive models, conducting numerical simulations, and ultimately driving innovation in materials. The creation of massive quantities of reliable Process–Structure–Property datasets is especially crucial for optimizing processing techniques of heat-resistant superalloys, which are characterized by their complex multi-element microstructures. Historically, developing these databases has been a convoluted endeavor fraught with challenges that demand significant investment in resources and time.

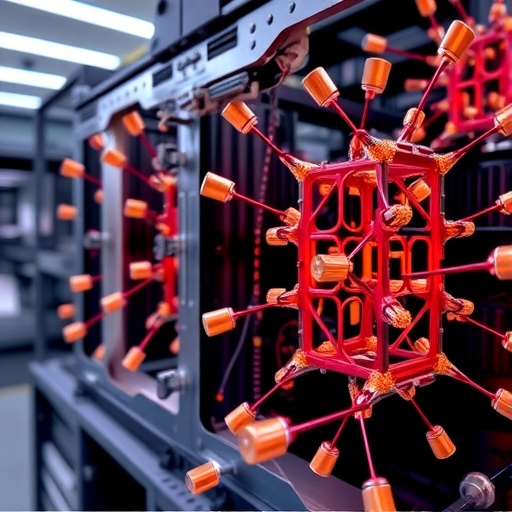

The revolutionary system developed by the NIMS research team enables the rapid compilation of largely expansive Process–Structure–Property datasets from a singular sample of a nickel-cobalt-based superalloy. This specific superalloy has been meticulously crafted by the institute for use in critical components such as aircraft engine turbine disks. The innovative design includes a gradient temperature furnace that facilitates thermal treatment across a wide spectrum of processing temperatures. This allows for the systematic mapping of various thermal conditions across the superalloy sample.

Electron microscopic techniques form an integral part of the data collection process, wherein advanced scanning electron microscopy is utilized for obtaining detailed measurements concerning precipitate parameters and yield stress. These measurements can be conducted automatically, thanks to an efficient Python API that governs the operation of the scanning electron microscope in conjunction with a nanoindenter. The automation streamlines the evaluation and processing of the collected data, enabling an unprecedented accumulation of Process–Structure–Property data.

The staggering efficiency of this automated system radically transforms the landscape of materials design. To put this into perspective, the volume of Process–Structure–Property data generated in just 13 days would have taken nearly seven years and four months to produce through traditional experimental approaches. This stark contrast highlights the transformative promise of automated systems within materials research. Moreover, it opens the door for rapid exploration and optimization of new materials, which is vital for meeting the increasing demands of modern technology and industries.

Looking ahead, the research team has ambitious plans to utilize this automated system for constructing extensive databases focused on various targeted superalloys. The power of this system extends beyond mere data generation; the team is also aiming to innovate new methodologies for acquiring vital high-temperature yield stress and creep data. Such advancements are crucial in understanding the mechanical behavior of materials under extreme conditions, which is paramount for the development of robust structural materials in aerospace applications.

Additionally, the researchers aspire to formulate multi-component phase diagrams based on the superalloy databases they compile. These diagrams are essential for materials design as they provide vital insights into the stability and compatibility of various components within complex alloys. This foundational understanding is key to exploring new concoctions of superalloys that possess favorable properties, aligning with the global shift toward a more sustainable future.

Ultimately, the overarching aspiration is to fabricate new heat-resistant superalloys that could play a pivotal role in achieving carbon neutrality. As the aerospace sector continues to push the boundaries of technology with the aim of reducing its environmental footprint, the integration of advanced materials becomes increasingly critical. The move towards data-driven approaches in materials science is expected to accelerate innovations significantly, facilitating the creation of lighter, stronger, and more efficient materials.

In conclusion, the development of this automated high-throughput system is not merely a technological feat; it represents a paradigm shift within the domain of materials science. By significantly accelerating the data generation process, this system opens new vistas for research and innovation. The implications extend beyond the realm of superalloys, potentially revolutionizing the development of a wide array of materials tailored for diverse applications. With this groundbreaking advancement, the future of materials design looks promising, brimming with possibilities and untapped potential.

Subject of Research:

Article Title: Automated System for High-throughput Process-Structure-Property Dataset Generation of Structural Materials: A γ/γ′ Superalloy Case Study

News Publication Date: 20-Jun-2025

Web References: http://dx.doi.org/10.1016/j.matdes.2025.114279

References: Materials & Design, a scientific journal.

Image Credits: Toshio Osada, National Institute for Materials Science; Takahito Ohmura, National Institute for Materials Science

Keywords

automated system, high-throughput, materials science, datasets, superalloy, Process–Structure–Property, aircraft engines, nickel-cobalt-based, data-driven design, phase diagrams, sustainability, carbon neutrality

Tags: accelerated materials research techniquesaerospace materials researchautomated high-throughput materials systemdata-driven materials design innovationsefficient materials testing methodologiesexperimental data significance in materialshigh-speed experimental analysis in engineeringmicrostructural analysis in materials scienceNational Institute for Materials Science advancementsProcess-Structure-Property datasetsstructural materials database creationsuperalloy dataset generation