In the quest to revolutionize cold storage and transportation without the downsides of melting ice, researchers have pioneered an innovative substance known as “jelly ice.” This groundbreaking material, developed through a one-step process using gelatin — a naturally derived biopolymer commonly found in food products — offers a sustainable, reusable, and compostable alternative to traditional ice. Unlike regular ice, which transforms into water and creates potentially hazardous melt puddles during thawing, jelly ice remains contained within a hydrogel structure, maintaining its integrity and avoiding messy or contaminatable runoff. This pioneering technology could significantly impact food preservation, medical shipment, and bioengineering sectors by providing a safe, eco-friendly cooling solution.

The development of jelly ice emerged from a simple but profound observation in grocery store seafood sections, where melting ice pools raised concerns about pathogen spread and food contamination. This practical problem inspired researchers Jiahan Zou and Gang Sun to explore gelatin as the base for a reusable cooling medium that could retain water even through multiple freeze-thaw cycles. Gelatin’s unique molecular composition — long proteins that form a three-dimensional hydrogel network — enables it to trap water molecules tightly within tiny pores. This structural characteristic resists water leakage even when the gel transitions from frozen to liquid states, a critical improvement over typical ice or frozen tofu, which releases water upon thawing.

Gelatin hydrogels, used here as a starting material, possess critical attributes for a practical reusable ice substitute. From a materials science perspective, these gels are physically crosslinked polymeric networks capable of phase transitions without structural collapse. They jellify due to the physical entanglement of protein strands, producing a stable mesh that hosts water uniformly. This uniform encapsulation allows jelly ice to maintain cooling properties based on the latent heat absorbed or released during water’s phase changes, although with an efficiency slightly below that of pure ice. Despite this, the material excels in reusability, microbial resistance, and avoiding contamination, offering up to 80% of the heat absorption capacity of conventional ice.

.adsslot_J4hPjt1n9b{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_J4hPjt1n9b{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_J4hPjt1n9b{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

One of the most significant advantages of jelly ice is its sustainability. Unlike conventional ice packs, which are typically encased in plastic and often discarded after use, jelly ice is fully compostable, breaking down into environmentally benign components. Moreover, it eliminates microplastic pollution risks, a growing concern linked to synthetic cooling gels. The research team reported that composted jelly ice even improves plant growth, suggesting an added circular economy benefit for agricultural waste integration. This eco-conscious design signals an important advancement in the drive to replace synthetic materials with bio-based, biodegradable alternatives that do not contribute to long-term pollution.

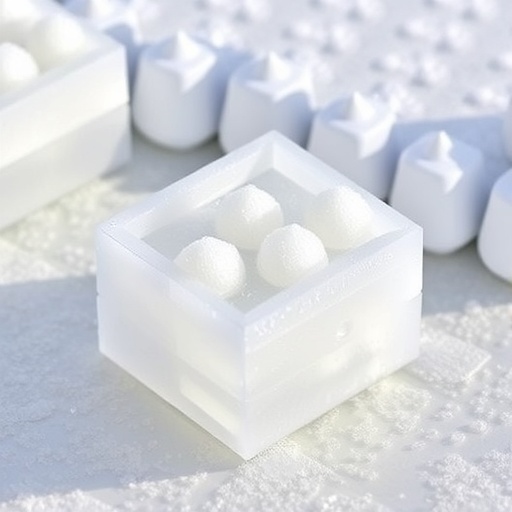

Beyond basic applications, jelly ice shows promise in specialized contexts where traditional ice is suboptimal or unavailable. Medical and biotechnological industries, for example, require reliable cool storage solutions that maintain sterile conditions and prevent moisture contamination. Jelly ice’s ability to withstand repeated freeze-thaw cycles and resist microbial proliferation makes it ideal for shipping sensitive pharmaceuticals and biological samples. Additionally, its moldability and customizable shapes allow tailoring for diverse containers and packaging sizes, markedly improving logistic flexibility compared to rigid ice blocks or bulky gel packs.

The underlying fabrication method for jelly ice emphasizes efficiency and scalability. Employing a streamlined one-step synthesis, the production process involves hydrating gelatin polymers with water and subjecting the mixture to controlled cooling, which prompts gel formation. This approach not only simplifies manufacturing but also allows easy adjustment of the material’s physical properties, such as stiffness and freezing point, by altering gelatin concentration or adding safe additives. Such tunability sets the stage for widespread adoption across industries with differing cooling requirements.

The conceptual origin of jelly ice traces back to the behavior of frozen tofu, a material known for entrapping water in a porous matrix. However, unlike tofu, which releases water upon thawing due to its structural breakdown, gelatin’s hydrogel maintains its structural fidelity and prevents leakage. This biological inspiration highlights the power of leveraging natural materials and mechanisms to meet engineering challenges — a principle increasingly embraced in sustainable materials science. The researchers’ success with gelatin hydrogels paves the way for exploring other biopolymers with similar properties for future innovations.

While jelly ice represents a notable breakthrough, market integration still lies ahead. Researchers acknowledge that comprehensive market analyses, product design refinements, and large-scale production validations will be necessary before jelly ice becomes a commercially available consumer product. The technology is licensed, suggesting active interest from industry stakeholders eager to capitalize on its sustainability advantages. If successfully commercialized, jelly ice could disrupt standard practices in food retail, cold chain logistics, and even everyday consumer use, offering a mess-free and eco-friendly cooling experience.

Importantly, the researchers are extending their work into developing protein-based coatings and scaffolds derived from plant proteins, such as soy, which hold potential for cultivating meat and other cellular agriculture applications. These efforts aim to broaden the suite of bio-derived polymeric materials contributing to a circular bioeconomy by valorizing agricultural byproducts and reducing reliance on petrochemical plastics. Advances in ultrasonic and chemical processing techniques have improved the processability of such plant proteins, opening exciting avenues in food safety and sustainability-focused materials science.

Zou, a lead investigator, emphasizes the power and versatility of natural biopolymers in crafting next-generation materials. Her research shows that mimicking nature’s design principles can yield functional materials with desirable mechanical, thermal, and environmental properties suited for food security and safety. This approach aligns well with the global imperative to innovate sustainable alternatives that balance performance with ecological responsibility, reflecting a growing recognition that future material solutions must be inherently regenerative.

Presented at the prestigious American Chemical Society’s Fall 2025 meeting, this research attracted attention for its interdisciplinary impact — bridging chemistry, materials science, food technology, and environmental sustainability. The jelly ice innovation exemplifies the transformative potential inherent in bio-based functional materials to address major societal challenges such as food waste, plastic pollution, and pathogen contamination. As the scientific community advances these innovations, the commercial ecosystem will likely witness an expansion of green materials replacing conventional synthetic solutions.

Ultimately, jelly ice is more than just a clever substitute for melting ice; it represents a step toward circular, regenerative materials that support sustainable food systems and cold chain logistics worldwide. Future developments may see the technology integrated into diverse applications—from everyday grocery displays and home use to critical medical shipments and cellular agriculture. This versatile biomaterial, derived from a simple yet powerful natural polymer, exemplifies the promise of biopolymer science in harmonizing technological progress with environmental stewardship.

Subject of Research: Sustainable bio-derived polymeric materials improving food security, food safety, and circular bioeconomy

Article Title: Sustainable bio-derived polymeric materials improving food security, food safety, and circular bioeconomy

News Publication Date: August 18, 2025

Web References:

https://acs.digitellinc.com/live/35/page/1204

https://acs.digitellinc.com/live/35/session/560625

https://youtu.be/qXofDLPriwg

Image Credits: UC Davis

Keywords

Chemistry, Materials, Food safety

Tags: biopolymer innovationscompostable cooling materialseco-friendly ice alternativesfood safety in transportationfreeze-thaw cyclesgelatin applications in bioengineeringhydrogel technologyjelly icemedical shipment coolingreducing food contaminationreusable cooling solutionssustainable food preservation