Credit: Figure adapted from Ind. Eng. Chem. Res. 2019 58 (14), 5686-5697. Copyright © 2019 American Chemical Society

An international collaboration led by scientists at Tokyo University of Agriculture and Technology (TUAT) , Japan, has developed a two-step method to more efficiently break down carbohydrates into their single sugar components, a critical process in producing green fuel.

The researchers published their results on April 10th in the American Chemical Society journal, Industrial & Engineering Chemical Research.

The breakdown process is called saccharification. The single sugar components produced, called monosaccharides, can be fermented into bioethanol or biobutanol, alcohols that can be used as fuel.

“For a long time, considerable attention has been focused on the utilization of homogenous acids and enzymes for saccharification,” said Eika W. Qian, paper author and professor in the Graduate School of Bio-Applications and Systems Engineering at the Tokyo University of Agriculture and Technology in Japan. “Enzymatic saccharification is seen to be a reasonable prospect since it offers the potential for higher yields, lower energy costs, and it’s more environmentally friendly.”

The use of enzymes to break down the carbohydrates could actually be hindered, especially in the practical biomass such as rice straw. A byproduct of rice harvest, rice straw consists of three complicated carbohydrates: starch, hemicellulose and cellulose. Enzymes cannot approach hemicellulose or cellulose, due to their cell wall structure and surface area, among other characteristics. They must be pre-treated to become receptive to the enzymatic activity, which can be costly.

One answer to the cost and inefficiency of enzymes is the use of solid acid catalysts, which are acids that cause chemical reactions without dissolving and becoming a permanent part of the reaction. They’re particularly appealing because they can be recovered after saccharification and reused.

Still, it’s not as easy as swapping the enzymes for the acids, according to Qian, as the carbohydrates are non-uniform. Hemicellulose and starch degrade at 180 degrees Celsius and below, and if the resulting components are heated further, the sugars produced discompose and are converted to other byproducts. On the other hand, degradation of cellulose only happens at temperatures of 200 degrees Celsius and above.

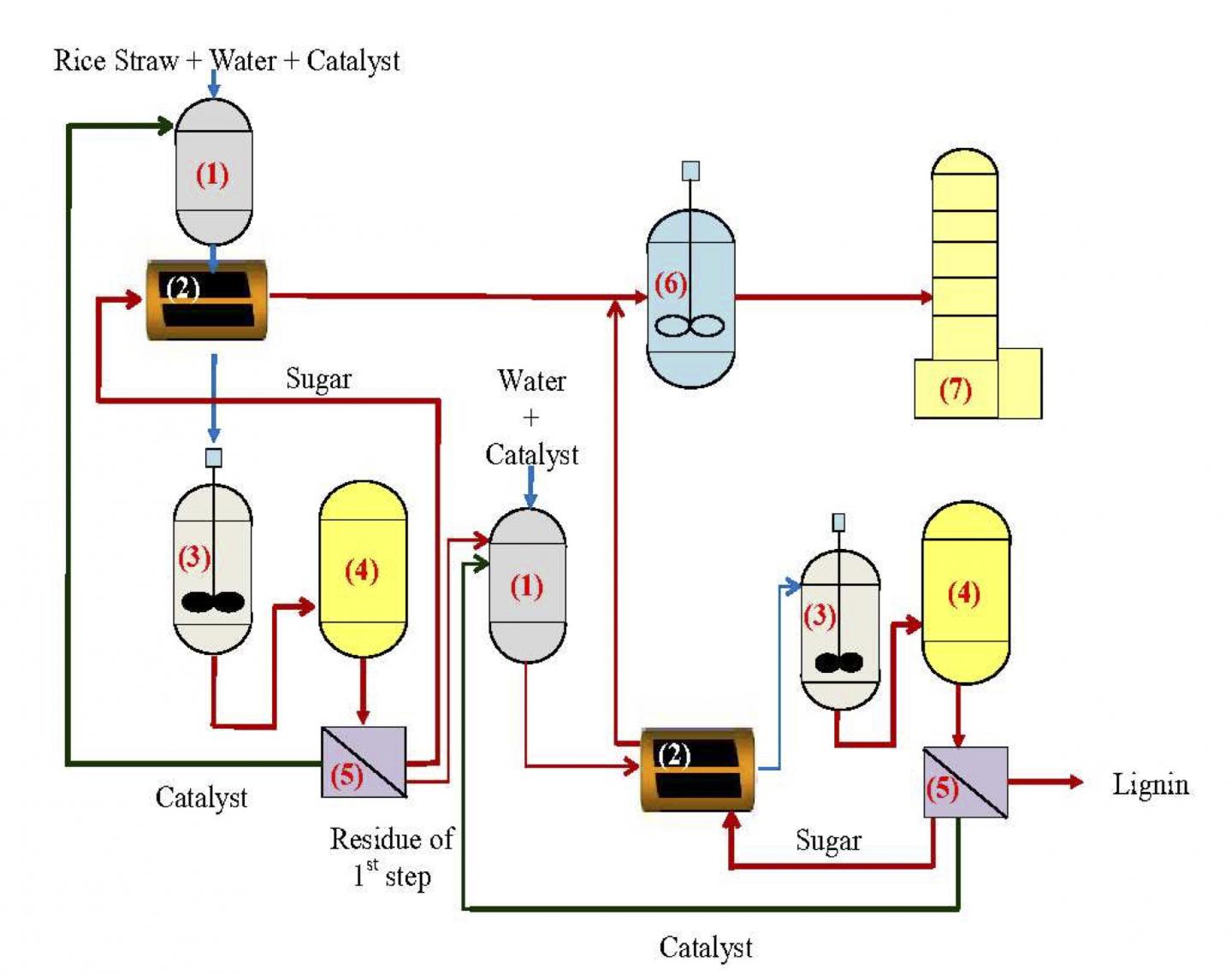

That’s why, in order to maximize the resulting yield of sugar from rice straw, the researchers developed a two-step process – one step for the hemicellulose and another for the cellulose. The first step requires a gentle solid acid at low temperatures (150 degrees Celsius and below), while the second step consists of harsher conditions, with a stronger solid acid and higher temperatures (210 degrees Celsius and above).

Overall, the two-step process not only proved effective, it produced about 30 percent more sugars than traditional one-step processes.

“We are now looking for a partner to evaluate the feasibility of our two-step saccharification process in rice straw and other various materials such as wheat straw and corn stoke etc. in a pilot unit,” Qian said. “Our ultimate goal is to commercialize our process to manufacture monosaccharides from this type of material in the future.”

###

The other authors are Luh Putu Pitrayani of the Anglo Chinese School Jakarta in Indonesia; Xiuhui Wang and Thanh Tung Nguyen, both of the Graduate School of Bio-Applications and Systems Engineering at the Tokyo University of Agriculture and Technology in Japan; Sen Li of the Shanghai Research Institute of Chemical Industry Co. Ltd. in China; and Jianglong Pu of the College of Biological, Chemical Sciences and Engineering at Jiaxing University in China.

For more information about the Qian laboratory, please visit http://senlab.

About Tokyo University of Agriculture and Technology (TUAT)

TUAT is a distinguished university in Japan dedicated to science and technology. TUAT focuses on agriculture and engineering that form the foundation of industry, and promotes education and research fields that incorporate them. Boasting a history of over 140 years since our founding in 1874, TUAT continues to boldly take on new challenges and steadily promote fields. With high ethics, TUAT fulfills social responsibility in the capacity of transmitting science and technology information towards the construction of a sustainable society where both human beings and nature can thrive in a symbiotic relationship. For more information, please visit http://www.

Original publication

Two-Step Saccharification of Rice Straw Using Solid Acid Catalysts

Luh Putu Pitrayani Sukma, Xiuhui Wang, Sen Li, Thanh Tung Nguyen, Jianglong Pu, and Eika W. Qian

Industrial & Engineering Chemistry Research 2019 58 (14), 5686-5697

DOI: 10.1021/acs.iecr.8b06473

Contact

Eika W. Qian, PhD

Professor, Department of Chemical Engineering.,

Research Institute of Engineering, TUAT, Japan

Email: [email protected]

Media Contact

Yutaka Nibu

[email protected]

Related Journal Article

http://dx.