In a groundbreaking stride towards the future of materials science, researchers from the University of Tokyo, in collaboration with international partners, have unveiled an innovative digital laboratory system capable of fully automating the synthesis, structural characterization, and physical property evaluation of thin-film materials. This avant-garde platform—termed dLab—ushers in a new era where robotic precision, machine learning, and standardized data protocols converge to streamline and accelerate materials discovery. The advancement holds promise to significantly transform both experimental workflows and data management in materials research.

At the heart of the dLab is a tightly integrated suite of modular instruments interconnected physically and digitally, enabling seamless transition from material production to multifaceted characterization without human intervention. This system autonomously fabricates thin-film samples with exacting control over synthesis conditions and subsequently conducts comprehensive analyses essential for understanding material functionalities. Widely recognized measurement techniques such as X-ray diffraction (XRD) and Raman spectroscopy are incorporated, allowing the system to non-destructively probe crystal structures and chemical bonds, respectively. Additionally, measurements of electrical conductivity and optical transmittance provide vital insights into the functional performance of these materials.

The elegance of dLab lies not only in its hardware orchestration but also in its robust data infrastructure. Each instrument outputs data in a unified XML-based format known as Measurement Analysis Instrument Markup Language (MaiML), a newly minted Japanese Industrial Standard established in 2024. This standardization facilitates seamless data aggregation, interoperability, and subsequent cloud-based analysis using bespoke software tools. By overcoming traditional data silos intrinsic to heterogeneous experimental systems, dLab fosters a truly data-driven environment where machine learning algorithms can be effectively employed to decipher intricate correlations across synthesis parameters and material properties.

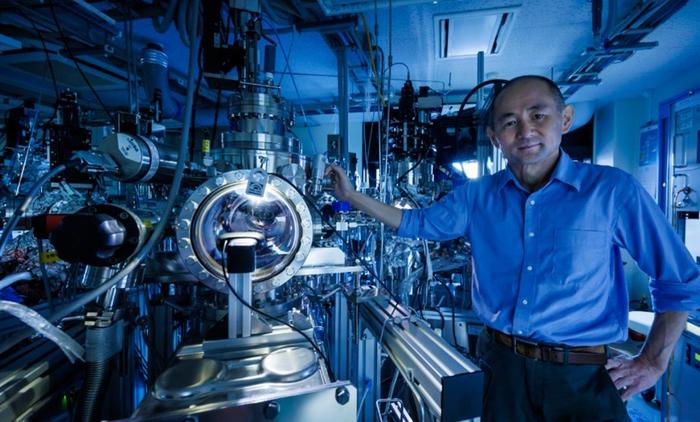

Professor Taro Hitosugi, leading the initiative at the University of Tokyo’s Graduate School of Science, emphasizes the revolutionary paradigm shift that dLab represents. Unlike conventional laboratories—which often serve as mere repositories of instruments dependent on manual operation—dLab reimagines the laboratory as a fully automated production factory for materials and data. This conceptual shift enables high-throughput experimentation, wherein large libraries of sample variations can be synthesized, measured, and analyzed rapidly and reproducibly, thereby drastically reducing the cycle time for materials development.

Demonstrating the capabilities of dLab, the team successfully executed the autonomous synthesis of lithium-ion positive-electrode thin films, materials pivotal to energy storage technologies. The system not only created these films under researcher-defined specifications but also automatically performed structural evaluation through XRD, confirming phase purity and crystallinity. This showcases the potential for dLab to expedite the iterative cycles of formulation, characterization, and optimization that are fundamental to battery materials research and beyond.

The implementation of dLab reflects an increasing recognition across the scientific community that integrating robotics, artificial intelligence, and standardized methodologies is essential to transcend current bottlenecks in experimental throughput and reproducibility. While machine learning has propelled theoretical predictions, the gap has long existed in automating experimental validation and data acquisition, which often remain labor-intensive and error-prone. dLab addresses this challenge directly, offering a scalable framework adaptable to various material systems and characterization methods.

However, the journey towards fully autonomous materials laboratories encounters several foundational hurdles. Paramount among these is the lack of universally accepted standards for sample dimensions, holder geometries, and data formats across solid-state research instruments. Solid materials manifest in diverse morphologies—from powders to bulk substrates—complicating automation. The development of MaiML under the aegis of the Japan Analytical Instruments Manufacturers Association (JAIMA) and governmental stakeholders marks a significant milestone in standardizing measurement data, laying the groundwork for broader interoperability essential to dLab’s vision.

Looking forward, the research collective aims to enhance the dLab’s orchestration software and scheduling algorithms to improve task management and enable simultaneous processing of multiple samples. Such advances will further amplify experimental throughput and efficiency. The ultimate aspiration is to foster a fully digitalized research and development ecosystem wherein researchers are liberated from routine tasks to concentrate their efforts on hypothesis generation, creative problem solving, and theory advancement.

Kazunori Nishio, a specially appointed associate professor at the University of Tokyo’s Institute of Science Tokyo and lead author of the accompanying research publication, underscores the transformative potential of this approach. “Our goal is to establish an environment that fully leverages human creativity by automating mundane experimental tasks and enabling data sharing at an unprecedented scale,” Nishio explains. By cultivating expertise in data-centric and robotic methodologies, the next generation of materials scientists can accelerate discovery cycles and uncover novel materials with optimized properties.

The ripple effects of dLab extend beyond laboratory efficiency; they have profound implications for sustainability and innovation capacity. Automated and standardized experimentation reduces resource consumption by minimizing trial-and-error and redundant measurements. Moreover, rapid data turnaround shortens the path from conceptual materials design to practical application, critical in addressing urgent challenges such as renewable energy storage, catalysis, and electronics.

While the current system excels in solid thin-film materials research, the framework established by dLab is inherently modular and adaptable. This flexibility opens avenues for expansion into diverse classes of materials, including complex alloys, heterostructures, and functional composites. Continued collaboration with instrument manufacturers and standardization bodies will be essential to amplify this modularity and embed dLab’s principles across the global materials research infrastructure.

In summary, the University of Tokyo’s dLab exemplifies a bold leap toward a future where autonomous experiments, machine intelligence, and standardized data protocols coalesce to redefine how materials science research is conducted. By enabling systematic, reproducible, and high-throughput investigations, this paradigm shift promises to accelerate innovation and deepen our fundamental understanding of materials, potentially heralding a new golden age of materials discovery driven by digital transformation.

—

Subject of Research: Development of a fully automated digital laboratory system for materials synthesis and evaluation with a modular measurement setup and standardized data format.

Article Title: Digital laboratory with modular measurement system and standardized data format

News Publication Date: 14-May-2025

References:

Kazunori Nishio, Akira Aiba, Kei Takihara, Yota Suzuki, Ryo Nakayama, Shigeru Kobayashi, Akira Abe, Haruki Baba, Shinichi Katagiri, Kazuki Omoto, Kazuki Ito, Ryota Shimizu, and Taro Hitosugi, “Digital laboratory with modular measurement system and standardized data format,” Digital Discovery: May 14, 2025, DOI: 10.1039/D4DD00326H

Image Credits: Junichi Kaizuka

Keywords

Materials science, autonomous experimentation, digital laboratory, thin films, machine learning, robotics, data standardization, Measurement Analysis Instrument Markup Language (MaiML), X-ray diffraction, Raman spectroscopy, lithium-ion batteries, materials automation, data-driven research

Tags: advanced materials discoveryautomated materials synthesisdata management in sciencedigital materials scienceelectrical conductivity measurementmachine learning in materials researchoptical transmittance analysisRaman spectroscopy applicationsrobotic laboratory systemsthin-film material characterizationUniversity of Tokyo research innovationsX-ray diffraction techniques