New approach could lead to more efficient and less polluting fuel combustion

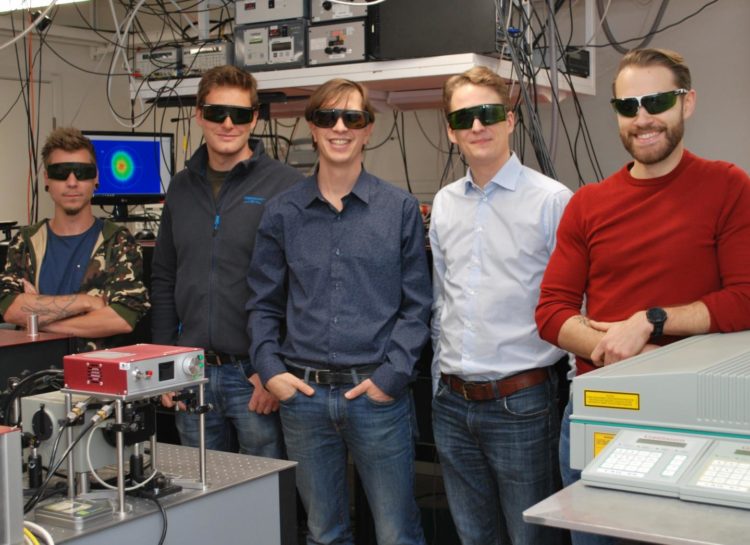

Credit: Edouard Berrocal, Lund University

WASHINGTON — Researchers have developed a new laser-based method that provides an unprecedented view of sprays such as the ones used for liquid fuel combustion in vehicle, ship and plane engines. The technique could provide new insights into these atomizing sprays, which are also used in a variety of industrial processes such as painting and producing food powders and drugs.

“We developed a new imaging method to better understand the transition from liquid to gas that occurs before fuel combustion,” said research team leader Edouard Berrocal from the Division of Combustion Physics, Department of Physics at Lund University in Sweden. “This information could be used to develop smarter fuel injection strategies, better fuel-air mixing, more efficient combustion and, ultimately, reduce pollutant emissions from combustion devices typically used for transportation.”

In Optica, The Optical Society’s journal for high impact research, Berrocal and colleagues from the Department of Physics’ Division of Atomic Physics describe a novel approach that combines x-rays and laser-induced fluorescence to observe and quantify atomizing spray phenomena that were not previously accessible. The fluorescence images provide details on the sprayed liquid’s form, including its size and shape, while the x-ray radiographs quantify how the liquid is distributed.

“Usually, images of atomizing sprays are blurry and don’t contain information about the spray’s interior,” said Diego Guénot, first author of the paper. “Our new imaging approach solves these problems and can even detect smaller amounts of liquid than have ever been detected before with x-rays.”

Seeing into a spray

Sprays are very difficult to visualize with normal light because their thousands of small droplets scatter light in all directions. X-ray beams, however, are also absorbed, making it possible to measure the amount of liquid present by detecting the amount of x-ray radiation transmitted through the spray.

This type of analysis usually requires x-rays generated by large synchrotrons, which are available at only a few specialized facilities around the world. However, the researchers overcame this barrier by using a new table-top laser-plasma accelerator developed by Olle Lundh’s team in the Division of Atomic Physics. It was designed to produce x-rays tailored for high-resolution and time-resolved x-ray imaging.

“Even though they are much smaller than a synchrotron, the new laser accelerators produce x-rays in the right energy range to be absorbed by liquids and can deliver it in femtosecond pulses that essentially freeze the spray motion for imaging,” said Lundh. “Also, the x-ray flux is high enough to produce a good signal over a wide area.”

In the laser-plasma accelerator, x-rays are generated by focusing an intense femtosecond laser pulse into a gas or a preformed plasma. The researchers also used these femtosecond laser pulses to perform two-photon fluorescence imaging. This fluorescence approach is often used in life science microscopy to provide high contrast images of submillimeter areas but has rarely been used to image sprays, which usually require an imaging area of a few square centimeters.

“Two-photon imaging of a relatively large area requires higher energy, ultrashort laser pulses,” said Berrocal. “The fact that we used an intense femtosecond laser beam to generate x-rays meant we could simultaneously perform x-ray and two-photon fluorescence imaging. Performing these two imaging modalities at the same time with a relatively large viewed area has not been done before.”

Getting a clear view

The researchers first tested the technique by generating x-rays and placing a spray in front of the x-ray camera. With the first image, it was immediately apparent that the spray could be clearly visualized. The researchers then modified the setup to add the two-photon fluorescence imaging. Using the combined technique to image water jets created by an automotive fuel injector produced a higher measurement sensitivity than has been achieved with the large synchrotron x-ray sources.

“This imaging approach will make studying sprays much easier for both academic and industry researchers because they will be able to perform studies, not only at the handful of synchrotron facilities, but also at various laser plasma accelerator laboratories over the world.” explained Guénot.

The researchers plan to expand the technique to obtain 3D images of sprays and study how they evolve over time. They also want to apply it to more challenging and realistic sprays such as biodiesel or ethanol direct-injection sprays as well as for spray systems used for gas turbines.

###

Paper: D. Guénot, K. Svendsen, J. B. Svensson, H. Ekerfelt, A. Persson, O. Lundh, E. Berrocal, “Simultaneous laser-driven X-ray and two-photon fluorescence imaging of atomizing sprays,” Optica, 7(2), XX, 131-134 (2020). DOI: https:/

About Optica

Optica is an open-access, journal dedicated to the rapid dissemination of high-impact peer-reviewed research across the entire spectrum of optics and photonics. Published monthly by The Optical Society (OSA), Optica provides a forum for pioneering research to be swiftly accessed by the international community, whether that research is theoretical or experimental, fundamental or applied. Optica maintains a distinguished editorial board of more than 60 associate editors from around the world and is overseen by Editor-in-Chief Prem Kumar, Northwestern University, USA. For more information, visit Optica.

About The Optical Society

Founded in 1916, The Optical Society (OSA) is the leading professional organization for scientists, engineers, students and business leaders who fuel discoveries, shape real-life applications and accelerate achievements in the science of light. Through world-renowned publications, meetings and membership initiatives, OSA provides quality research, inspired interactions and dedicated resources for its extensive global network of optics and photonics experts. For more information, visit osa.org.

Media Contacts:

Aaron Cohen

(301) 633-6773

[email protected]

[email protected]

Media Contact

James Merrick

[email protected]

202-416-1994

Related Journal Article

http://dx.