Lithium-ion batteries (LIBs) scientists from the South China University of Technology have summarized recent progress in surface modification of nickel-rich cathode materials based on the Periodic Table to provide a clear development of advanced LIBs.

Credit: By Jing Li, Wentao Zhong, Qiang Deng, Qimeng Zhang and Chenghao Yang.

Lithium-ion batteries (LIBs) scientists from the South China University of Technology have summarized recent progress in surface modification of nickel-rich cathode materials based on the Periodic Table to provide a clear development of advanced LIBs.

Publishing in the journal International Journal of Extreme Manufacturing, the team led by researchers based on the Periodic Table in order to further understand how surface modification improves the performance of nickel-rich cathode materials. The team summarize the mechanism of surface modification based on the Periodic Table for the first time.

The findings could have a widespread impact on the future development of nickel-rich cathode materials. When a new type of nickel-rich cathode materials and particles is in contact with these surface modifications, both particles and structures change their configuration in response to the degeneration of the capacity.

Such surface modifications on nickel-rich cathode materials govern the performance of LIBs for clean electricity generation, as well as determining the efficiency of clean energy and underpinning much electronic equipment.

One of the lead researchers, Professor Chenghao Yang, commented, “Given the widespread industrial and scientific importance of such behavior, it is truly surprising how much we still have to learn about the mechanism of how modified elements behave on surfaces in contact with the bulk structure. One of the reasons information is missing the absence of techniques able to yield many alternative nickel-rich cathode materials for LIBs.”

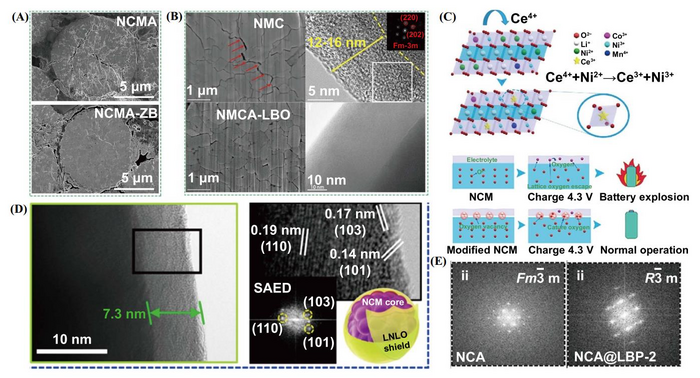

Surface modification is one of the main techniques that prevent the decomposition of nickel-rich cathode materials from the electrolyte. However, the synthetic process of nickel-rich cathode materials requires a high-dry environment, and the structure of materials changes in moist air. Professor Chenghao Yang explained, “In this review, we summarized the novel modification technology based on the Periodic Table in order to provide more designed strategies for surface modification.”

Prof. Chenghao Yang has studied the nickel-rich cathode materials for LIBs, thus here his group have summarized and discussed those same techniques to develop high-performance nickel-rich cathode materials for LIBs. A series of nickel-rich cathode materials were synthesized and modified by specific reagent and technology. These novel materials allow them to provide high-performance nickel-rich cathode materials for LIBs, enabling in-deep mechanisms to be captured showing the analysis of granular and structural stability.

By analyzing how the modified elements were synthesized on the surface and in the structure and comparing them to the electrochemical performance provided by colleagues at the South China University of Technology, the researchers were able to understand the effect of the modified elements on the high performance of nickel-rich cathode materials for LIBs. The surface modification for precursor was found to be beneficial for the occupation of the modified elements and also suppress the phase transition with respect to layered structure to rock salt structure.

The team studied nickel-rich cathode materials that are promising for advanced LIBs and the experimental technology they have discussed and developed can be used for many different applications.

Professor Chenghao Yang said, “This is a milestone achievement and it is only the beginning—we are already looking to use these modifications to support the development of nickel-rich cathode materials for LIBs, needed to achieve the world’s net zero ambitions.”

About IJEM:

International Journal of Extreme Manufacturing (IF: 10.036) is a new multidisciplinary, double-anonymous peer-reviewed and fully open access journal uniquely covering the areas related to extreme manufacturing. The journal is devoted to publishing original articles and reviews of the highest quality and impact in the areas related to extreme manufacturing, ranging from fundamentals to process, measurement and systems, as well as materials, structures and devices with extreme functionalities.

Visit our webpage, Like us on Facebook, and follow us on Twitter and LinkedIn.

Journal

International Journal of Extreme Manufacturing

DOI

10.1088/2631-7990/ac92ef

Article Title

Recent progress in synthesis and surface modification of nickel-rich layered oxide cathode materials for lithium-ion batteries

Article Publication Date

31-Oct-2022