Coal-fired power plants have been in place for a long time to meet the global demands for power generation. Needless to say, there are environmental and human health concerns to be addressed on this front. While there are ongoing efforts to transition to renewable energy resources, coal-fired power plants may not become obsolete just yet. Against this backdrop, it is pertinent to explore how the efficiency of these coal-fired boilers can be improved while mitigating their harmful effects on the environment, namely greenhouse gas emissions, acid rain, and photochemical smog generation, and the human health.

Credit: Gyungmin Choi from Pusan National University, Korea

Coal-fired power plants have been in place for a long time to meet the global demands for power generation. Needless to say, there are environmental and human health concerns to be addressed on this front. While there are ongoing efforts to transition to renewable energy resources, coal-fired power plants may not become obsolete just yet. Against this backdrop, it is pertinent to explore how the efficiency of these coal-fired boilers can be improved while mitigating their harmful effects on the environment, namely greenhouse gas emissions, acid rain, and photochemical smog generation, and the human health.

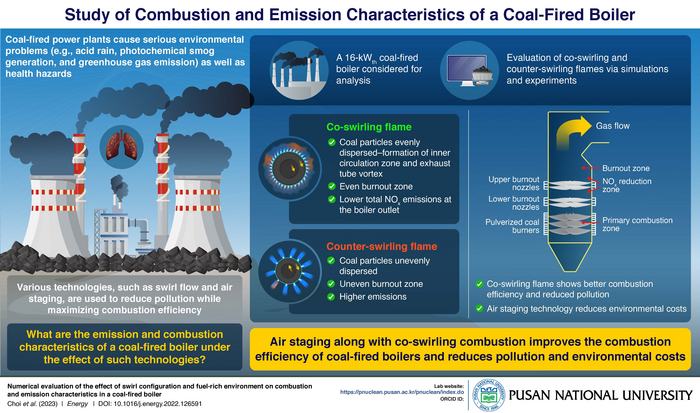

To this end, various combustion methods like air an staging and swirl flow have been proposed. However, the efficacy of these technologies in mitigating the pollutant emissions while maximizing the burnout performance has remained unclear. Now, in a recent study made available online on 31 December 2022 and to be published in Volume 268, Issue 1 of the journal Energy on 01 April 2023, an international team of researchers led by Prof. Gyungmin Choi of Pusan National University, Korea analyzed the effectiveness of combining swirl flow and air staging in improving the combustion performance and reducing pollution. “The exhaust tube vortex (ETV) structure accompanying the swirl flow improves flame stability and combustion performance, but has the disadvantage of generating a large amount of NOx emissions. In contrast, air staging technology creates a fuel-rich environment in the primary combustion zone, which has a positive effect on NOx reduction but negatively affects combustion performance,” explains Prof. Choi. “Therefore, if these two technologies are appropriately combined and applied in real life, a synergistic effect that reduces the emission of air pollutants as well as improves combustion performance can be expected.”

Accordingly, the team employed both simulations and experiments to study the combined effects of different swirl configurations and air staging within a 16-kWth retrofitted down-fired pulverized coal boiler. The coal boiler was composed of three sections: the swirl burner, the boiler, and the exhaust pipe. For staged combustion, staged air was divided into two sides and injected tangentially into the boiler. Liquified petroleum (LPG) gas was used for preheating and flame stabilization. The staged-air and LPG flow rates were regulated, and for each setting, the temperature was measured using thermocouples. Additionally, the amount of gas-phase species was measured using a multi-gas analyzer.

Air staging with two swirl configurations, namely co-swirling and counter-swirling flames, were evaluated to understand which of these is more beneficial in terms of reducing pollutant emissions. In the case of the co-swirling burner, where the air and fuel circulated in the same sense, the coal particles were evenly distributed owing to the formation of inner circulation zone and the ETV–two vital features for optimizing the design of coal-fired boilers.

Further, the team observed an even burnout zone for the co-swirling configuration, which ensured complete combustion of the fuel, reducing the gas species emissions. It also facilitated an increased conversion of chemical energy into thermal energy, boosting the combustion efficiency. In contrast, counter-swirling burners showed uneven coal particle distribution, uneven burnout, and increased NOx emissions, suggesting that a co-swirling configuration was the better option. Additionally, the team showed that air staging technology reduced the environmental costs from $0.003 to $0.015 per day.

Overall, the insights from this study could prove to be extremely valuable in solving the environmental problems and health hazards related to coal-fired power plants. “We have identified and studied the structure and flame of the ETV for the first time, and will continue researching and striving to utilize it in the combustion-based industry,” concludes an optimistic Prof. Choi.

***

Reference

DOI: https://doi.org/10.1016/j.energy.2022.126591

Authors: Minsung Choi a, Taegam Hwang b, Yeseul Park c, , Xinzhuo Li d , Junsung Kim b , Kibeom Kim e , Yonmo Sung f , and Gyungmin Choi b,

Affiliations:

aDepartment of Automotive Engineering, Gangneung-Wonju National University

b School of Mechanical Engineering, Pusan National University

c School of Convergence Science, Pusan National University

d School of Energy and Power Engineering, Changsha University of Science and Technology

e Department of Mechanical Engineering and Science, Kyoto University

f Department of Energy & Mechanical Engineering, Gyeongsang National University

Pusan National University Website

Pusan National University, located in Busan, South Korea, was founded in 1946, and is now the no. 1 national university of South Korea in research and educational competency. The multi-campus university also has other smaller campuses in Yangsan, Miryang, and Ami. The university prides itself on the principles of truth, freedom, and service, and has approximately 30,000 students, 1200 professors, and 750 faculty members. The university is composed of 14 colleges (schools) and one independent division, with 103 departments in all.

About the author

Gyungmin Choi is a Professor of School of Mechanical Engineering at Pusan National University (PNU) and the head of Research and Business Development Foundation. His group (clean energy laboratory) has been actively involved in research at the energy division at PNU since 2004. His laboratory publishes over 5–6 papers per year, contributing to advances in combustion control, coal utilization technologies, compressor, refrigeration cycle, etc. Before coming to PNU, Prof. Choi worked as a researcher at renowned Japanese research institutes such as the Japan Industrial Furnace Manufacturing Associate, NEDO, National Aerospace Laboratory, and Japan Aerospace Exploration Agency in Japan. In 1997 and 2002, he received his doctorates from PNU and Osaka University, respectively.

Website: https://pnuclean.pusan.ac.kr/pnuclean/index.do

Journal

Energy

DOI

10.1016/j.energy.2022.126591

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Numerical evaluation of the effect of swirl configuration and fuel-rich environment on combustion and emission characteristics in a coal-fired boiler

Article Publication Date

1-Apr-2023

COI Statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper