Unexpected pipeline failures can lead to leakages that pollute the environment and compromise public safety, thereby underscoring the importance of accurate, real-time pipeline monitoring. Pipelines on naval ships that are a part of fire-extinguishing and cooling systems are especially prone to damage due to frequent projectile launches and collisions.

Credit: Yun-ho Shin from Pusan National University

Unexpected pipeline failures can lead to leakages that pollute the environment and compromise public safety, thereby underscoring the importance of accurate, real-time pipeline monitoring. Pipelines on naval ships that are a part of fire-extinguishing and cooling systems are especially prone to damage due to frequent projectile launches and collisions.

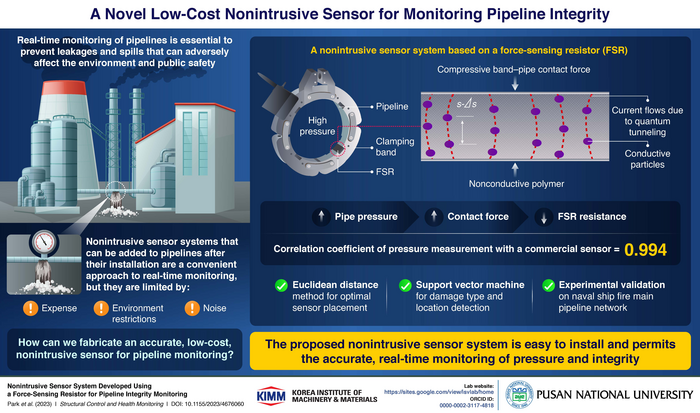

There are two kinds of sensors for this purpose—intrusive and non-intrusive. Intrusive sensors are highly accurate sensors that measure pressure or mass flow must be pre-installed during the construction of the pipeline. Non-intrusive sensors, on the other hand, use light and sound-based measurement systems. They can be installed after a pipeline is constructed, thereby offering more flexibility. However, non-intrusive sensors are expensive are affected by environmental conditions and noise.

To overcome these limitations, a group of researchers led by Assistant Professor Yun-ho Shin of the Department of Naval Architecture and Ocean Engineering at Pusan National University, has proposed a novel non-intrusive sensor system based on a low-cost, force-sensing resistor (FSR). The research was conducted jointly with the Korea Institute of Machinery and Materials (KIMM) and was made published online in the Structural Control and Health Monitoring journal on 7 February 2023.

The sensor consists of a stiff clamping band with an FSR that contains conductive particles in a non-conductive polymer. “When the pressure inside a pipe increases, the contact force between the pipe and clamping band also increases. That, in turn, compresses the FSR. As a result, the conductive particles come closer to each other, and current starts flowing in the non-conductive polymer due to quantum tunneling. This brings down the FSR resistance. Hence, the sensor can indirectly measure pipe pressure and detect changes in it,” explains Prof. Shin. The researchers found that the novel sensor’s measurements showed a 99.4% correlation with a commercial, intrusive sensor, emphasizing its accuracy.

The researchers then utilized the Euclidean distance method to determine where the sensors must be optimally placed in a pipeline network. Based on its results, they installed two sensors on a naval ship-like fire main pipeline system. Their data was fed to support vector machine—a machine learning-based classification algorithm—which allowed them to detect the type and location of damages in the system rapidly and accurately.

“The FSR-based sensors can be applied to any pipeline system in industries with a high risk of pipe failure, including nuclear power plants and naval ships. They will also reduce required manual work by automating pipe integrity monitoring,” concludes Prof. Shin.

The novel, low-cost, FSR-based non-intrusive sensor system paves the way toward more robust pipeline safety, thereby displaying the potential to protect human health, as well as environmental health.

***

Reference

DOI: https://doi.org/10.1155/2023/4676060

Authors: Jin-woo Park1, Byung Chang Jung1, Sang Hyuk Lee1, Young Cheol Huh1, and Yun-ho Shin2,

Affiliations: 1Department of System Dynamics, Korea Institute of Machinery & Materials, South Korea; 2 Department of Naval Architecture & Ocean Engineering, Pusan National University, South Korea

About Pusan National University

Pusan National University, located in Busan, South Korea, was founded in 1946, and is now the no. 1 national university of South Korea in research and educational competency. The multi-campus university also has other smaller campuses in Yangsan, Miryang, and Ami. The university prides itself on the principles of truth, freedom, and service, and has approximately 30,000 students, 1200 professors, and 750 faculty members. The university is composed of 14 colleges (schools) and one independent division, with 103 departments in all.

Website: https://www.pusan.ac.kr/eng/Main.do

About the author

Yun-ho Shin is an Assistant Professor at the Department of Naval Architecture and Ocean Engineering at Pusan National University (PNU). In 2009, he received a Ph.D. from the Korea Advanced Institute of Science and Technology. He was a Senior Researcher at the Korea Institute of Machinery and Materials before joining PNU. Prof. Shin has published 150 research articles which have been cited 400 times. His research interests include vibration visualization, vibration control, and naval ship survivability. His group is currently developing an autonomous recovery and monitoring system for pipeline integrity and image processing technology for vibration visualization.

Lab website address: https://sites.google.com/view/isvlab/home

ORCID id: 0000-0002-3117-4818

Journal

Structural Control and Health Monitoring

DOI

10.1155/2023/4676060

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Non-intrusive Sensor System Developed using a Force-sensing Resistor for Pipeline Integrity Monitoring

Article Publication Date

7-Feb-2023

COI Statement

The authors declare no conflict of interest.