A research group led by Nagoya University has developed an innovative approach to creating anti-counterfeiting labels for high-value goods. Their findings, published in ACS Applied Materials & Interfaces, enhance the security of the currently used cholesteric liquid crystals (CLCs) by adding fluorescent dyes to produce florescent CLCs (FCLCs).

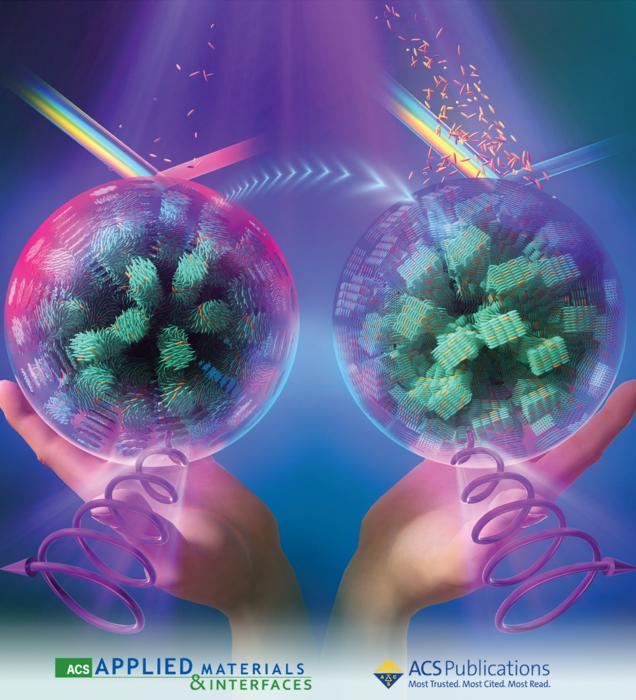

Credit: ACS Publications

A research group led by Nagoya University has developed an innovative approach to creating anti-counterfeiting labels for high-value goods. Their findings, published in ACS Applied Materials & Interfaces, enhance the security of the currently used cholesteric liquid crystals (CLCs) by adding fluorescent dyes to produce florescent CLCs (FCLCs).

Using this unique technology, the group created unique labels with almost impossible-to-counterfeit security features. These advanced labels are designed to protect valuable items, important documents, and sensitive products by generating distinctive visual patterns that are difficult to replicate without specialized tools and knowledge.

To create these specialized tags, scientists mix fluorescent dyes with CLCs, causing the helical structure of the crystals to twist either to the left or right—a property known as chirality. This twisting determines how the crystals reflect light, producing a specific “light signature”. The precise control over this twisting and the resulting light patterns makes these labels almost impossible to counterfeit.

Under normal light, the FCLCs appear as solid colors with no visible information. However, when viewed through a circular polarizer, hidden features emerge, revealing intricate details that serve as a primary security layer. Additionally, the FCLCs can include components that respond only to ultraviolet light, offering a secondary verification method.

As Professor Yukikazu Takeoka from Nagoya University explains: “The correct information is revealed only when both decoding tools—left circularly polarized light (CPL) and ultraviolet light—are employed. This dual-layer security significantly enhances the protection offered by existing CLC-based anti-counterfeiting tags.”

The FCLCs’ unique iridescent colors shift depending on the concentration of chiral dopant and the polarization of the light source, adding another layer of complexity for counterfeiters attempting to replicate the labels.

By carefully adjusting the concentration of the chiral dopant, the researchers have fine-tuned the material to reverse the direction of circular polarization. This allows the FCLCs to reflect right-handed CPL while absorbing left-handed CPL, further complicating any counterfeiting attempts.

The development of FCLC particles with both circularly polarized structural color and circularly polarized luminescence marks a significant milestone in the field of anti-counterfeiting. This innovative approach holds tremendous potential for securing high-value goods and protecting sensitive products from forgery.

In the future, this technology could evolve to include additional security features, such as QR codes that become visible only under polarized light or passwords that appear under UV light. As Jialei He, a member of the research team, said: “This dual-verification system would provide two layers of protection: the structural color visible under polarized light and the fluorescent emission visible under UV light.”

With these advancements, FCLCs could soon become an integral part of the security protocols for a wide range of industries, offering an unparalleled defense against counterfeiting and ensuring the integrity of high-value products.

Journal

ACS Applied Materials & Interfaces

DOI

10.1021/acsami.4c08331