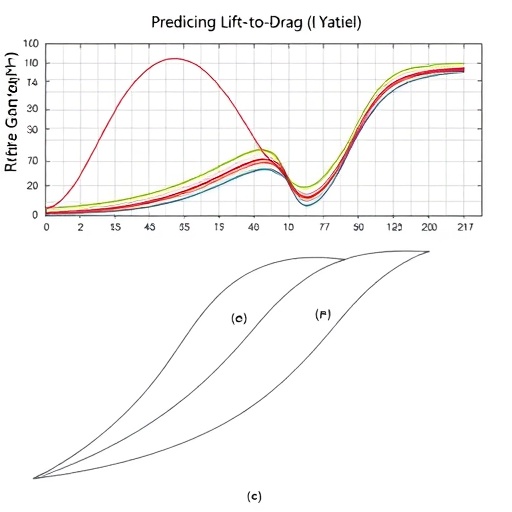

In a breakthrough study, researchers have introduced an innovative machine learning framework dedicated to predicting the aerodynamic lift-to-drag ratio for multi-stepped airfoils. This method marks a significant advancement in aerodynamics applications, offering potential improvements in aerospace engineering and fluid mechanics. The significance of effective lift-to-drag ratio prediction cannot be overstated, as it directly influences the efficiency and performance of various aerodynamic bodies, including aircraft wings and turbine blades. The new framework, detailed by Elshewey, Aziz, and Marzouk, provides a novel approach to enhancing aerodynamic design processes.

Traditionally, the complexities of fluid dynamics present significant challenges in accurately predicting aerodynamic performances. Engineers have relied heavily on computational fluid dynamics (CFD) simulations, which, while powerful, often require substantial computational resources and time. This is where machine learning shows promise; by leveraging vast datasets from existing aerodynamic tests, the new framework can provide rapid and reliable predictions of lift-to-drag ratios. The transformation of empirical data into actionable insights through algorithms is revolutionizing the way engineers think about airfoil design.

Multi-stepped airfoils, which consist of segmented geometries, can offer unique aerodynamic properties that often outperform traditional blade designs. These structures can be optimized for various flight conditions, making them particularly appealing for modern aviation applications. By integrating the proposed machine learning framework with multi-stepped airfoil geometry, researchers aim to unlock unprecedented levels of optimization that can lead to both enhanced operational efficiency and reduced environmental impacts due to improved fuel economy.

One of the key innovations in this study is the architecture of the machine learning model itself. The researchers employed advanced algorithms that are capable of learning complex relationships within the dataset without needing extensive pre-processing. This enables the model to adapt to a variety of operational conditions and geometrical configurations, enhancing its versatility and predictive power. Such adaptability is essential in a field where airfoil designs are continually evolving to meet new regulatory and performance standards.

In the past, collecting the necessary data for building reliable predictive models required extensive experimentation. The framework developed by Elshewey and colleagues significantly reduces this burden by utilizing existing datasets effectively. This allows for quicker iterations in design, enabling engineers to explore new concepts rapidly. By bridging the gap between theoretical predictions and practical applications, it provides a compelling advantage to aerospace designers facing tight deadlines and demanding performance metrics.

Collaborative validation of the model with experimental wind tunnel data showcased its accuracy and reliability in predicting the lift-to-drag ratios across a range of conditions. These rigorous validation efforts ensure that the model can stand up to real-world testing, an essential criterion for any aerodynamics application. Furthermore, the study outlines the steps taken for model training, including data augmentation techniques to enhance dataset diversity, thereby improving the model’s generalizability.

The implications of the researchers’ findings extend beyond just aerodynamics. Industries ranging from automotive to renewable energy can gain insights from this machine-learning framework. Electric vehicles and wind turbine designs, for instance, stand to benefit significantly from improvements in aerodynamic efficiencies as the quest for sustainability intensifies. As global industries strive to minimize carbon footprints, enhanced performance metrics derived from precise predictions of lift-to-drag ratios become increasingly pivotal.

The integration of machine learning in aerodynamic research epitomizes a broader trend in engineering disciplines toward data-driven solutions. Emphasizing the importance of cross-disciplinary collaboration, this research aligns well with efforts in artificial intelligence and aviation technology. It underscores the notion that traditional engineering practices can be augmented by modern computational methodologies, fostering a new generation of engineers adept in both their fields and in data analytics.

Looking ahead, this research opens avenues for further exploration in various aerospace applications. As machine learning technologies continue to advance and datasets expand, future iterations of the framework could incorporate additional variables such as real-time environmental data and dynamic operational conditions. This adaptability could significantly enhance the real-time decision-making capabilities of aerodynamic engineers, offering solutions tailored to specific flight regimes.

Moreover, stakeholders in the aerospace community must recognize the potential of these advancements and consider integrating such frameworks into their design protocols. By streamlining design processes and reducing time-to-market, firms could maintain competitive edges while adhering to increasingly strict performance benchmarks set by regulatory bodies. As the study suggests, the potential for widespread application is both timely and relevant given the current trajectory of global aerodynamics.

In conclusion, the introduction of a machine learning framework for the prediction of lift-to-drag ratios of multi-stepped airfoils promises to redefine critical aspects of aerodynamic design and optimization. The meticulous approach employed by Elshewey, Aziz, and Marzouk highlights a transformative shift towards integrating advanced computational techniques into traditional engineering domains. As this framework gains traction, we may witness significant improvements in not only aerospace engineering but also in various sectors striving for enhanced aerodynamic performance.

The collaborative effort demonstrates the power of interdisciplinary research and the potential for machine learning technologies to revolutionize engineering practices. This sets an exciting precedent for upcoming innovations in aerodynamics, paving the way for future studies that will push the boundaries of what is possible in the realm of fluid mechanics.

As the aerospace industry moves towards embracing these computational methodologies, the insights drawn from this study will serve as a foundational stone upon which future aeronautical achievements will be built. The interconnectivity of technology, data, and expertise signifies a future where rapid advancements in design and engineering principles will continue to unfold.

Through the lens of this groundbreaking research, we are reminded that the does not end with theoretical knowledge but thrives on practical applications that shape the very fabric of our technological landscape.

Subject of Research: Aerodynamic lift-to-drag ratio prediction of multi-stepped airfoils using machine learning.

Article Title: A machine learning framework for aerodynamic lift-to-drag ratio prediction of multi-stepped airfoils.

Article References:

Elshewey, A.M., Aziz, M.A., Marzouk, S.A.W. et al. A machine learning framework for aerodynamic lift-to-drag ratio prediction of multi-stepped airfoils.

AS (2025). https://doi.org/10.1007/s42401-025-00422-5

Image Credits: AI Generated

DOI: 01 December 2025

Keywords: Machine learning, aerodynamics, lift-to-drag ratio, multi-stepped airfoils, aerospace engineering.

Tags: aerodynamic design optimizationaerospace engineering innovationscomputational fluid dynamics advancementsempirical data in aerodynamicsenhancing aerodynamic performancefluid mechanics applicationslift-to-drag ratio predictionmachine learning in aerodynamicsmodern aviation technologiesmulti-stepped airfoilsrapid prediction algorithmssegmented airfoil geometries