New approach offers practical way to make multilayer perovskite solar cells

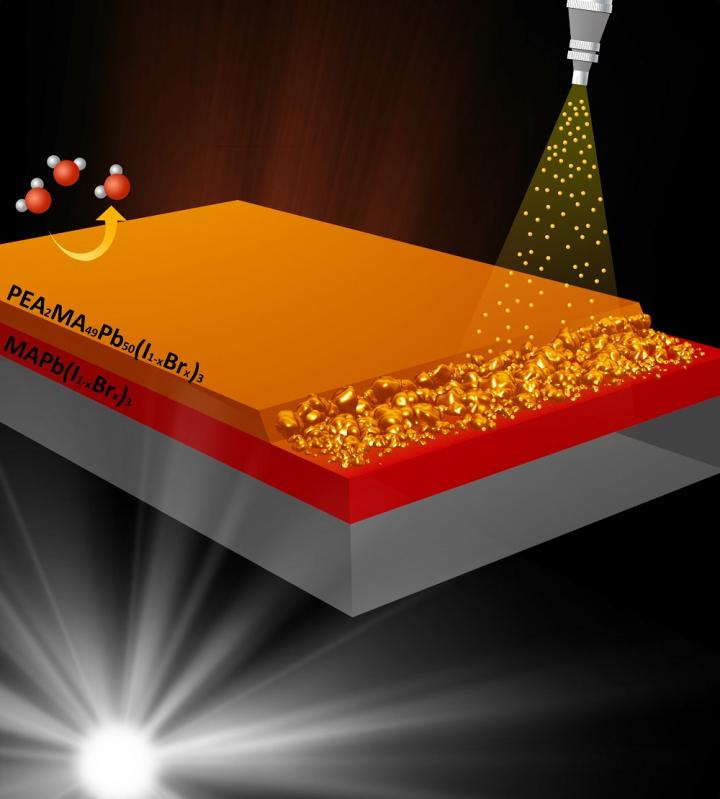

Credit: Pongsakorn Kanjanaboos, Mahidol University

WASHINGTON — Although perovskites are a promising alternative to the silicon used to make most of today’s solar cells, new manufacturing processes are needed to make them practical for commercial production. To help fill this gap, researchers have developed a new precision spray-coating method that enables more complex perovskite solar cell designs and could be scaled up for mass production.

Perovskites are promising for next-generation solar cells because they absorb light and convert it to energy with better efficiency and potentially lower production costs than silicon. Perovskites can even be sprayed onto glass to create energy-producing windows.

“Our work demonstrates a process to deposit perovskite layer by layer with controllable thicknesses and rates of deposition for each layer,” said research team leader Pongsakorn Kanjanaboos from the School of Materials Science and Innovation, Faculty of Science, Mahidol University in Thailand. “This new method enables stacked designs for solar cells with better performance and stability.”

In the Optical Society (OSA) journal Optical Materials Express, Kanjanaboos and colleagues describe their new spray coating method, called sequential spray deposition, and show that it can be used to create a multilayer perovskite design. Applying different perovskite materials in each layer can allow customization of a device’s function or the ability to meet specific performance and stability requirements.

A better way to spray

One of the advantages of perovskites are that they are solution processable, meaning that a solar cell is made by drying liquid perovskite into a solid at a low temperature. This fabrication process is much easier and less expensive than making a traditional silicon solar cell, a process that requires very high temperatures and cutting a solid material into wafers.

However, the solution process typically used to make perovskites does not allow multilayer designs because the upper layer tends to dissolve the already-dried lower layer. To overcome this challenge, the researchers turned to a process known as sequential spray deposition in which tiny droplets of a material are applied to a surface.

After trying different spray coating methods, they found one that worked at temperatures around 100 °C. They then optimized the spray parameters to ensure that the tiny droplets dried and crystalized into solid perovskite immediately upon contact with the already-dried lower layer.

Building a multi-layer device

“With our spray coating process, the solution of the upper layer doesn’t disturb the solid film making up the first layer,” said Pongsakorn. “Endless combinations of stacked perovskite architectures with any number of layers can be designed and created with precise control of thicknesses and rates of deposition for each layer.”

The researchers demonstrated the technique by depositing a perovskite material with high stability on different perovskite material with better electrical properties. This double-layer semi-transparent perovskite device showed clearly defined layers and simultaneously achieved high performance and good stability.

The researchers plan to use the new approach to make multilayer perovskite devices with new functions and combinations of performance and stability that were not possible before.

###

Paper: K. Amratisha, J. Ponchai, P. Kaewurai, P. Pansa-ngat, K. Pinsuwan, P. Kumnorkaew, P. Ruankham, P. Kanjanaboos, “Layer-by-layer spray coating of a stacked perovskite absorber for perovskite solar cells with better performance and stability under humid environment,” Opt. Mater. Express 10, 7, 1497-1508 (2020).

DOI: https:/

Optical Materials Express

Optical Materials Express is an open-access journal focusing on the synthesis, processing and characterization of materials for applications in optics and photonics. It is published by The Optical Society (OSA) and emphasizes advances in novel optical materials, their properties, modeling, synthesis and fabrication techniques; how such materials contribute to novel optical behavior; and how they enable new or improved optical devices. The editor-in-chief is Alexandra Boltasseva from Purdue University, USA. Optical Materials Express is available online at OSA Publishing.

About The Optical Society

Founded in 1916, The Optical Society (OSA) is the leading professional organization for scientists, engineers, students and business leaders who fuel discoveries, shape real-life applications and accelerate achievements in the science of light. Through world-renowned publications, meetings and membership initiatives, OSA provides quality research, inspired interactions and dedicated resources for its extensive global network of optics and photonics experts. For more information, visit osa.org.

Media Contact:

[email protected]

Media Contact

James Merrick

[email protected]

Original Source

https:/

Related Journal Article

http://dx.