Patented technology cuts rubber waste; Novel rubber aerogels are ultra-light, highly absorbent, durable, and traps heat and sound

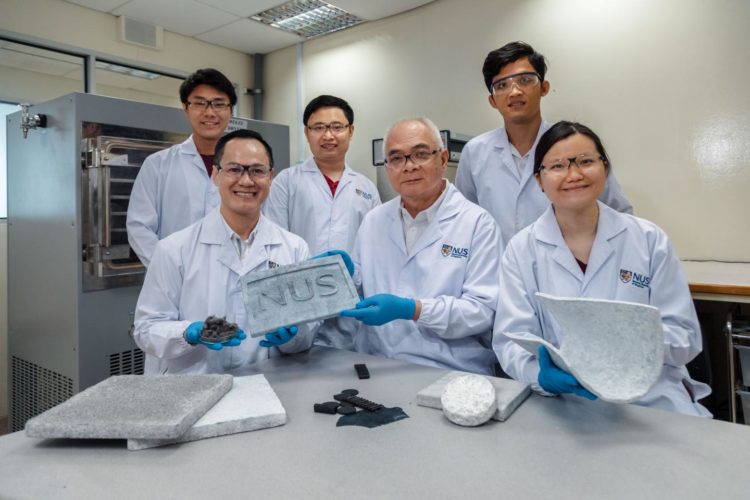

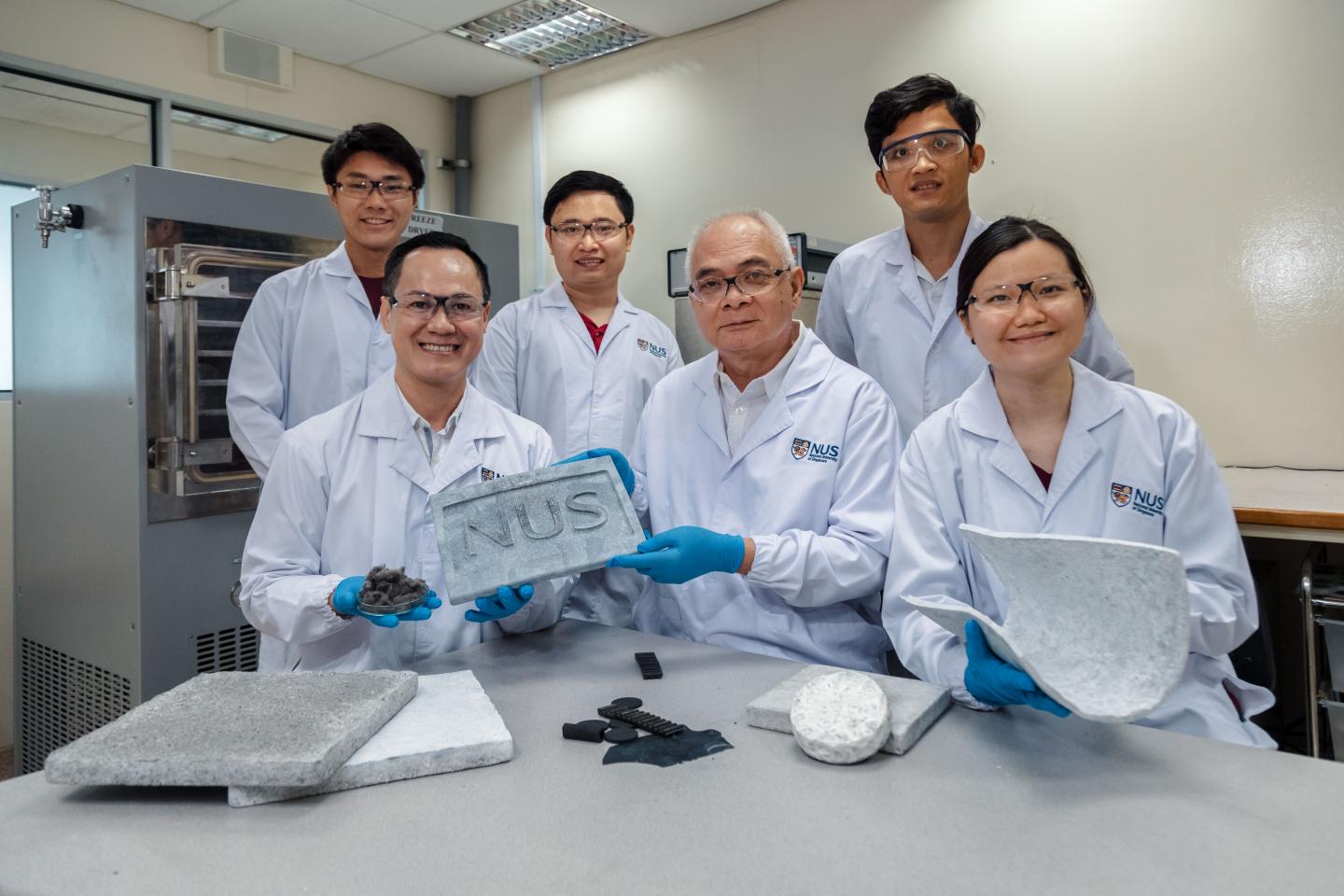

Credit: National University of Singapore

A team of researchers from the National University of Singapore (NUS) has achieved a major technological breakthrough by converting waste rubber tyres into super-light aerogels that have a wide range of applications. This is the first time that aerogels are made from waste rubber tyres. The new rubber aerogels demonstrate remarkable properties – they are extremely light, highly absorbent, very durable, and they are also very efficient at trapping heat and sound.

By upcycling waste rubber into products of a higher commercial value, this new technology promotes a wider use of scrap tyres, and offers an eco-friendly way to recycle used rubber. A patent for this novel technology has been filed.

To boost the research efforts of the team and raise public awareness of recycling, Mapletree Investments, a leading real estate developer with a strong focus on environmental sustainability, has recently made a gift of about US$108,000 (S$155,000) to NUS.

Scrap tyres – A significant waste problem

Every year, about 1 billion scrap tyres are generated worldwide. Rubber tyres are highly durable and non-biodegradable. Only 40 per cent are recycled into low-value-added products, while 49 per cent are incinerated to generate energy, and at least 11 per cent end up in landfills. Although landfills are commonly practised, landfills sites are running out and there is also a risk of the consequential leachate causing environmental pollution. Furthermore, burning rubber produces toxic substances that pose health and safety concerns.

“Although 40 per cent of waste rubber tyres are recycled, the rate of recycling worldwide remains low because processing used rubber is costly and energy-intensive, coupled with a lack of monetary incentive. Our team has decided to focus on creating rubber aerogels from used rubber tyres because they are a cheap and abundant source of raw materials. By converting waste rubber tyres into high-value aerogels, we could enhance the monetary incentive for recycling rubber and in turn, cut down rubber waste,” explained Associate Professor Duong Hai-Minh, who leads the research team from the Department of Mechanical Engineering at NUS Faculty of Engineering.

Mr Edmund Cheng, Mapletree Chairman, said, “Mapletree has always placed great emphasis on integrating sustainable designs into our developments. This project which aims to turn rubber waste into aerogel materials via green technology is aligned to our commitment to reduce negative environmental impact. We are excited that part of the support will also fund the refurbished lab facility for applied research and education on the potential of recycling technology. It is our hope that through education, one of our key corporate social responsibility pillars, there will be more awareness on environmental issues.”

Simple, cost-effective and eco-friendly production process

To create the rubber aerogels, recycled car tyre fibres are first blended into finer fibres. These fine rubber fibres are then soaked in water and very small amount of chemical cross-linkers. Next, the mixture of rubber fibres and eco-friendly solvents is dispersed uniformly using a stirrer for 20 minutes. The uniform suspension gel is then freeze-dried at minus 50 degrees Celsius for up to 12 hours to produce rubber aerogels.

Assoc Prof Duong said, “The fabrication process is simple, cost-effective and eco-friendly. The entire production process takes between 12 to 13 hours to complete and it only cost less than US$7 to produce a sheet of rubber aerogel that is 1 sqm in size and 1cm thick. The process can also be easily scaled up for mass production. This makes rubber aerogels a commercially attractive product.”

Highly versatile rubber aerogels

The novel rubber aerogels created by the NUS team possess remarkable properties for many applications:

- Extremely light and stiffer than commercial foam

- Highly porous: This makes rubber aerogels good absorbents for removal of spilled oil. They are two times more absorbent than conventional absorbents such as the polypropylene mat.

- Excellent sound adsorption: Rubber aerogels are 27 per cent more effective than the commercial foam absorber with the same thickness.

- Excellent heat insulation: Rubber aerogels have high heat resistance. A piece of rubber aerogel with a thickness of one inch (2.54 cm) has a heat transfer limit that is equivalent to 25 standard glass window panes.

- Highly durable: Most aerogels are extremely brittle and friable (i.e. they tend to fragment and pulverise), but rubber aerogels can spring back to its original shape after compression. This unique property makes them suitable as insulation material for industrial purposes such as in subsea systems, oil refineries and industrial buildings, and also in homes, refrigerators, as well as personal items such as jackets and shoe insoles.

- When coated with a chemical called methoxytrimethylsilane, the rubber aerogels become extremely water-repellent and they can be used to prevent moisture from corroding or damaging insulation equipment.

“Potential markets of aerogels are huge. For example, vehicle noise and thermal comfort are vital in vehicle designs – the global automotive heat and sound insulation solution market are expected to reach US$3.2 billion by 2022 . In addition, the global oil spill management market is expected to reach US$182.7 billion by 2025,” added Professor Nhan Phan-Thien, who is a senior member in the research team.

Commercialisation and new applications

Assoc Prof Duong, Prof Nhan and their team are looking forward to realising the positive environmental impact of aerogels by working with Mapletree and industry partners to commercialise and scale up this novel technology. With the generous contribution from Mapletree, the NUS team will be able to conduct further studies to enhance the performance of the rubber aerogels, explore other applications as well as using other types of waste materials to convert into aerogels.

A video on this technological breakthrough is available at: https:/

###

Media Contact

Fun Yip

[email protected]

65-651-61374

Original Source

http://news.