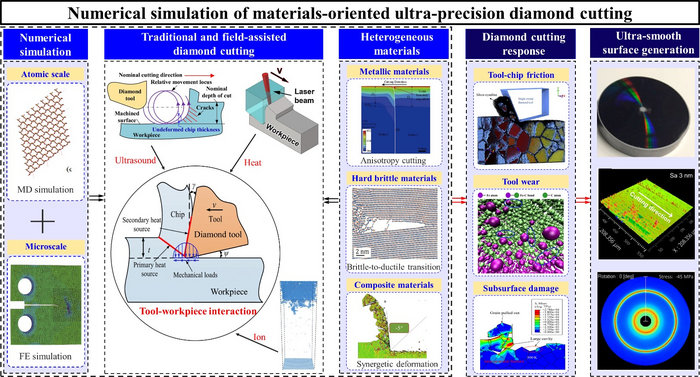

Publishing in the International Journal of Extreme Manufacturing (IJEM), researchers from Harbin Institute of Technology, Huazhong University of Science and Technology, Guizhou University and Ruhr-University Bochum present a brief review on the application of numerical simulations in addressing the impact of properties and microstructures of workpiece materials on the diamond cutting mechanisms of different types of workpiece materials, such as metallic, hard brittle materials and composite materials. In addition, the effect of applying an external energy field to the diamond cutting of difficult-to-cut materials is also discussed.

Credit: By Liang Zhao, Junjie Zhang, Jianguo Zhang, Houfu Dai, Alexander Hartmaier and Tao Sun.

Publishing in the International Journal of Extreme Manufacturing (IJEM), researchers from Harbin Institute of Technology, Huazhong University of Science and Technology, Guizhou University and Ruhr-University Bochum present a brief review on the application of numerical simulations in addressing the impact of properties and microstructures of workpiece materials on the diamond cutting mechanisms of different types of workpiece materials, such as metallic, hard brittle materials and composite materials. In addition, the effect of applying an external energy field to the diamond cutting of difficult-to-cut materials is also discussed.

The anisotropic deformation behavior among single crystal grains in diamond cutting of polycrystalline materials can be well described at the microscopic scale by crystal plasticity finite element simulation, which provides bases for the fundamental understanding of formation mechanisms as well as suppressing strategy of grain boundary surface steps on the machined surface.

The variation of the tool-chip friction state with cutting temperature can be effectively captured by the thermos-mechanical coupling sticking-sliding friction criterion embedded in the finite element model. In addition, the diamond tool wear can be suppressed by introducing textures on the cutting tool.

The fundamental understanding of phase transformation and cracking events through simulations is crucial for revealing the brittle-to-ductile transition mechanisms of hard brittle materials, thus enabling the rational selection of optimized parameters for enhanced ductile machinability.

The physics-based numerical model is critical for providing predicted results that are in line with experimental data for composite materials. The real microstructural characteristics of reinforced phase as well as the proper treatment of reinforced phase-matrix interface are essentially needed to accurately represent the tool-phases interactions in numerical simulations of diamond cutting of composites.

The configuration of external fields (vibration field, thermal field and ion implantation field) and their interactions with workpiece material without loss of physics is critical for revealing the mechanisms of field-assisted diamond cutting of difficult-to-machine materials with enhanced machinability by numerical simulations.

One of the lead researchers, Professor Junjie Zhang, commented, ” For the Atomic and Close-to-atomic Scale Manufacturing that deals with the processing of materials at the atomic scale with pronounced surface size effect, ultra-precision diamond cutting also plays an important role for its achievable sub-nanometer machining accuracy. The multiscale numerical simulation, such as finite element simulation at the microscopic scale and molecular dynamics simulation at the nanoscale, have become more popular for their capability to provide dynamic insights into ongoing diamond-cutting processes of a variety of materials, such as material deformation, chip formation, cutting force evolution and surface formation.”

First author Dr. Liang Zhao commented, “Despite the wide applications of different simulation methods utilized in the exploration of the diamond cutting process, there are still issues or challenges that are needed to be addressed for better comparison of predicted results with experimental data. In the present work, we present a compact review on the recent advances in advanced numerical simulations of diamond cutting of a variety of materials, which differs in properties, microstructures and constituents. The aspects reported in this work present guidelines for the numerical simulations of ultra-precision mechanical machining responses for a variety of materials.”

Prof. Alexander Hartmaier, Director of the Interdisciplinary Center for Advanced Materials Simulation at Ruhr-Universität Bochum said, “Future research on the numerical simulations of materials-oriented diamond cutting could be further recommended from the development of the high precision physics-based finite model, mainly aiming for increasing the prediction accuracy of simulation results for advanced structured materials compared to experimental data.”

About IJEM:

International Journal of Extreme Manufacturing (IF: 10.036) is a new multidisciplinary, double-anonymous peer-reviewed and diamond open-access without article processing charge journal uniquely covering the areas related to extreme manufacturing. The journal is devoted to publishing original articles and reviews of the highest quality and impact in the areas related to extreme manufacturing, ranging from fundamentals to process, measurement and systems, as well as materials, structures and devices with extreme functionalities.

Visit our webpage, Like us on Facebook, and follow us on Twitter and LinkedIn.

Journal

International Journal of Extreme Manufacturing

DOI

10.1088/2631-7990/acbb42

Article Title

Numerical simulation of materials-oriented ultra-precision diamond cutting: review and outlook

Article Publication Date

23-Feb-2023