A new publication from Opto-Electronic Advances, 10.29026/oea.2023.230029 discusses non-contact Microsphere ultrafast laser nanopatterning technology.

Credit: OEA

A new publication from Opto-Electronic Advances, 10.29026/oea.2023.230029 discusses non-contact Microsphere ultrafast laser nanopatterning technology.

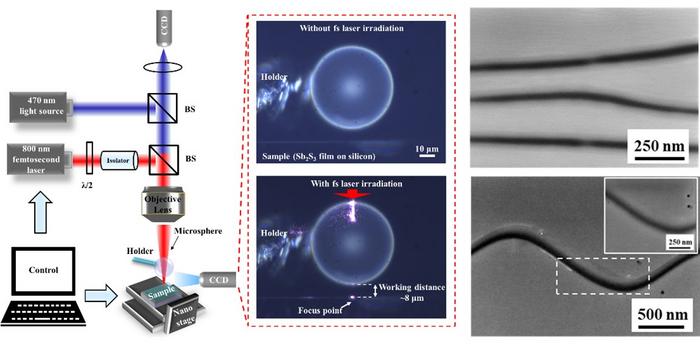

In the past decades, the development of nano-fabrication technology is driven by the need to increase the density of components and performance, which requires high accuracy in material processing and the capability of manufacturing in an atmospheric environment. Compared to other advanced processing methods, ultrafast laser processing has been recognized as one of the most extensively used tools for micro/nano-structuring. However, the key challenge of ultrafast laser processing to produce extremely small features is the optical diffraction limit. The heat affected zone via these techniques is still much larger than the nano-structures, which mostly exhibit >300 nm melting zone. Using a dielectric microsphere as a near-field lens for super-resolution nano-imaging and nano-fabrication has attracted great research interest. The optical phenomenon known as photonic nano-jet can contribute to laser beam focusing to overcome the diffraction limit. To increase the microsphere ultrafast laser processing throughput, the self-assembly method and micro-lens arrays lithography have been developed to fabricate surface patterns at a fast speed and low cost. In addition to nano-hole structures achieved by contact mode, the microsphere femtosecond laser fabrication can also realize arbitrary structures on sample surfaces in non-contact mode. By lifting the microsphere to form a gap between the sample and the microsphere, the working distance can be increased to several micrometers. This strategy leads to the microsphere working in far field. In this case, the feature size of surface structures can only be reduced to ~300 nm by the 405 nm lamp, 512 nm, and 800 nm femtosecond laser irradiation, which is still far from the optical diffraction limit. Thus, how to achieve a good balance between the working distance and feature size is a vital issue for microsphere assisted laser fabrication.

To overcome the above problems, the research group of Prof. Minghui Hong from Xiamen University and the National University of Singapore, and Prof. Tun Cao from Dalian University of Technology jointly reported an ultrafast laser processing technology based on non-contact microspheres, realizing <50 nm functional nano-patternings on the surface of phase change materials. In non-contact mode, the microsphere is placed on a specially designed holder, and the nano-structures can be obtained by flexibly controlling of microsphere in x-y-z scanning. In this case, the distance between the microsphere and the sample is in the order of microns. Via the femtosecond laser irradiation of microsphere, this new technology enables the high speed machining of finer feature nano-structures in non-contact mode in various conditions.

The researchers also analyzed and explained the forming mechanism of these nanostructures. By theoretical calculation, the focused spot size of the incident laser passing through the 50 µm microsphere is only ~678 nm. Due to the nonlinear effects of ultrafast laser, including two-photon absorption and top threshold effect, the feature of nano-structures can be reduced down to sub-50 nm. Therefore, the surface nano-structures are attributed to the co-effect of the microsphere focusing, the two-photon absorption, and the top threshold effect of the ultrafast laser irradiation.

This method provides a new idea for ultrafine laser surface nano-machining, and its machining efficiency and machining freedom are expected to be further optimized and improved via microsphere array and microsphere engineering.

# # # # # #

The research group of the Center for Laser Application in Xiamen University has 26 researchers, including one academician of Singapore Academy of Engineering, one senior researcher, one assistant professor, two postdoctoral, and sixteen students. The Team leader Prof. Hong Minghui is an academician of Singapore Academy of Engineering and a national high-level talent. He joined Xiamen University as a full-time professor in August 2022 and was appointed as Tan Kah Kee Chair Professor. He is the director of the Faculty of Engineering of Xiamen University, the Dean of Pen-Tung Sah Institute of Micro-Nano Science and Technology, and the chief scientist of Kah Kee Innovation Laboratory. Prof. Hong is a Fellow of Optical Society of America (OSA), International Society for Optics and Photonics (SPIE), and Institute of Engineers, Singapore (IES). He is also a Founding Fellow and Vice President of International Academy of Photonics and Laser Engineering (IAPLE). Additionally, he is the Chairman of an NUS spun-off company: Phaos Technology Pte. Ltd. He has published more than 500 papers and co-authored 15 academic monographs in international journals such as Nature, Nature Nanotechnology, Science Advances, Nature Communications, etc. He has 42 patents from China, Singapore, the United States, Germany, and other countries, 2 of which have been industrialized.

# # # # # #

Opto-Electronic Advances (OEA) is a high-impact, open access, peer reviewed monthly SCI journal with an impact factor of 8.933 (Journal Citation Reports for IF2021). Since its launch in March 2018, OEA has been indexed in SCI, EI, DOAJ, Scopus, CA and ICI databases over the time and expanded its Editorial Board to 36 members from 17 countries and regions (average h-index 49).

The journal is published by The Institute of Optics and Electronics, Chinese Academy of Sciences, aiming at providing a platform for researchers, academicians, professionals, practitioners, and students to impart and share knowledge in the form of high quality empirical and theoretical research papers covering the topics of optics, photonics and optoelectronics.

# # # # # #

More information: http://www.oejournal.org/oea

Editorial Board: http://www.oejournal.org/oea/editorialboard/list

All issues available in the online archive (http://www.oejournal.org/oea/archive).

Submissions to OEA may be made using ScholarOne (https://mc03.manuscriptcentral.com/oea).

ISSN: 2096-4579

CN: 51-1781/TN

Contact Us: [email protected]

Twitter: @OptoElectronAdv (https://twitter.com/OptoElectronAdv?lang=en)

WeChat: OE_Journal

# # # # # #

Lin ZY, Liu K, Cao T, Hong MH. Microsphere femtosecond laser sub-50 nm structuring in far field via non-linear absorption. Opto-Electron Adv 6, 230029 (2023). doi: 10.29026/oea.2023.230029

Journal

Opto-Electronic Advances

DOI

10.29026/oea.2023.230029