In a groundbreaking advancement poised to redefine the capabilities of sustainable materials, researchers from Tsinghua University and the Chinese Academy of Sciences have engineered a novel supramolecular elastomer known as BNOSE. This innovative elastomer harnesses the dynamic interplay of boron-nitrogen (B–N) coordination and boron-oxygen (B–O) dynamic bonds to simultaneously achieve remarkably high mechanical performance alongside efficient chemical recyclability—a feat that challenges the long-standing trade-offs in elastomer design.

Elastomers have long been foundational to technological progress, serving indispensable roles in industries ranging from automotive to flexible electronics. Yet, their environmental footprint remains a pressing concern. Conventional thermoset elastomers, while mechanically robust due to their permanent cross-linked networks, suffer from notoriously poor recyclability. Conversely, thermoplastic elastomers offer easier recycling routes but often at the cost of diminished strength and durability. BNOSE transcends these limitations by integrating reversible dynamic bonding, thereby combining toughness and recyclability in a uniquely balanced material system.

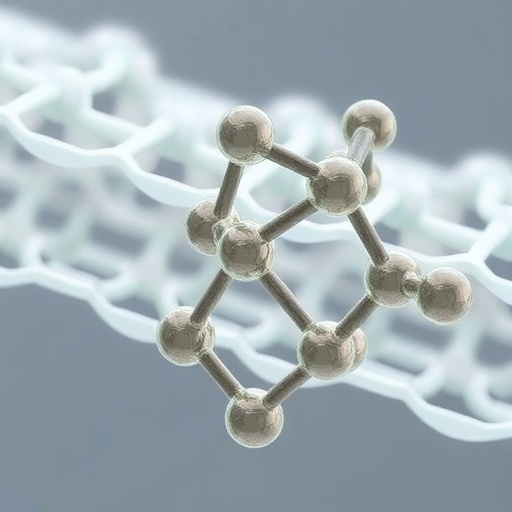

Central to the BNOSE architecture are two distinct yet synergistic bonding motifs. The first involves reversible B–N coordination bonds formed through the association of boron centers with pyridine moieties along the polymer chains. These bonds form strong interchain linkages that endow the material with exceptional tensile strength exceeding 43 MPa and impressive toughness values above 121 MJ/m³. The second motif comprises B–O bonds within the polymer backbone, which confer a built-in depolymerization mechanism activated under mild chemical conditions, most notably in ethanol solvents.

This chemical responsiveness is a pivotal innovation. Unlike traditional recycling approaches relying on high temperatures or metal catalysts, BNOSE’s B–O bonds undergo alcoholysis in ethanol, leading to mild and efficient depolymerization. This process enables the recovery of monomeric constituents—specifically pyridinboric acid and polytetrahydrofuran (PTMEG)—with yields surpassing 80%, highlighting both the environmental and economic potential of this recycling strategy. Such gentle recovery pathways are particularly advantageous for preserving sensitive components in advanced materials applications.

The research team meticulously elucidated the molecular underpinnings of BNOSE’s mechanical and chemical properties through a combination of density functional theory (DFT) calculations and experimental validation. DFT analyses revealed that the B–N coordination bond energy of 4-pyridine boric acid is significantly higher than that of its isomeric counterpart, 3-pyridine boric acid, which translated experimentally into superior tensile strength and elastic modulus for BNOSE-Py4 compared to control variants. This precise molecular engineering underscores the critical impact of strategic monomer selection and positioning on macroscopic material properties.

Equally compelling is BNOSE’s remarkable strain tolerance, boasting elongations exceeding 800%, an attribute rare for chemically recyclable elastomers. This high extensibility, coupled with robust tensile strength, positions BNOSE favorably for demanding applications in soft robotics and flexible electronics, where materials are subjected to repeated large deformations without loss of function or integrity.

The reversibility of the dynamic bonds enables not only chemical depolymerization but also facile material reprocessing. Due to their linear polymeric nature, BNOSE elastomers can be dissolved, recovered, and remolded into new forms multiple times, offering an elegant solution to the challenge of circular material use. This recyclability is complemented by the distinct degradation and recovery routes facilitated by the differential energies of the B–N and B–O bonds, providing versatility in end-of-life management strategies.

From a sustainability perspective, BNOSE emerges as a paradigm-shifting material, circumventing the environmental costs associated with current elastomer waste management practices that often involve landfill accumulation or incineration. By facilitating high-efficiency recycling under mild conditions, BNOSE offers a path toward drastically reducing the ecological impact of elastomer use in consumer and industrial products.

Looking forward, the research paves the way for expanding the scope of boron-based dynamic bonds in polymer science. By exploring a broader array of functional boric acid derivatives as polymeric monomers, the tunable mechanics and recyclability of such supramolecular elastomers could be refined further, enabling tailored properties for diverse high-performance applications that require sustainability without compromise.

This innovative study exemplifies the power of molecular precision in material design, where subtle changes in bonding orientation and strength dramatically influence macro-scale behavior. It heralds a future where recyclable high-performance elastomers are not only feasible but also economically and environmentally viable, addressing critical demands in advanced manufacturing, robotics, wearable technology, and beyond.

Furthermore, BNOSE’s gentle chemical recycling approach addresses a critical bottleneck in material circularity—facilitating polymer recovery without reliance on energy-intensive or toxic processes. Such advancements are crucial for moving toward a circular economy in polymer materials, reducing reliance on virgin petrochemical feedstocks and minimizing environmental emissions.

The scalability of the BNOSE design is especially promising. Its modular construction strategy suggests adaptability to a wide range of polymer backbones and functional groups, highlighting potential for customization to meet specific industrial needs. This adaptability will be essential for integrating sustainable elastomers into existing manufacturing frameworks and emerging technologies alike.

As the materials science community embraces the imperatives of sustainability, breakthroughs like BNOSE underscore the critical role of supramolecular chemistry. Harnessing dynamic, reversible interactions at the molecular level affords unprecedented control over material lifecycle without sacrificing the mechanical demands essential for real-world applications—a truly transformative advance.

In conclusion, the development of BNOSE marks a significant leap forward in the field of sustainable polymer materials. Its combination of strong mechanical properties, chemical recyclability under mild conditions, and versatile processing capabilities positions it as a leading candidate to revolutionize the elastomer industry and advance circular material systems globally. This innovative work, published in CCS Chemistry, represents not only a feat of chemical ingenuity but also a beacon of sustainable materials innovation for the future.

Subject of Research: Not applicable

Article Title: Mechanically Strong, Chemical Recycling Supramolecular Elastomers via Boron-Based Dynamic Bonds

News Publication Date: 28-Aug-2025

Web References:

https://www.chinesechemsoc.org/journal/ccschem

http://dx.doi.org/10.31635/ccschem.025.202506135

References:

Original research article published in CCS Chemistry, DOI: 10.31635/ccschem.025.202506135

Image Credits: CCS Chemistry

Keywords

Supramolecular chemistry

Tags: BNOSE elastomer technologyboron-based dynamic bondsboron-nitrogen coordinationboron-oxygen dynamic bondschemical recyclability of materialseco-friendly materials in industryelastomer design trade-offshigh-performance elastomersmechanical strength of elastomersreversible bonding in polymerssupramolecular elastomerssustainable material innovations