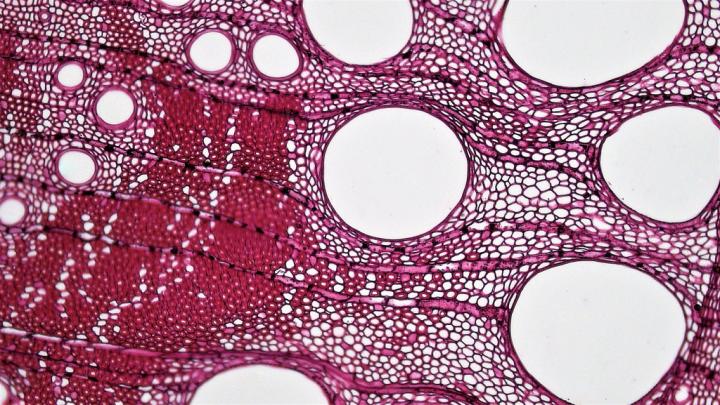

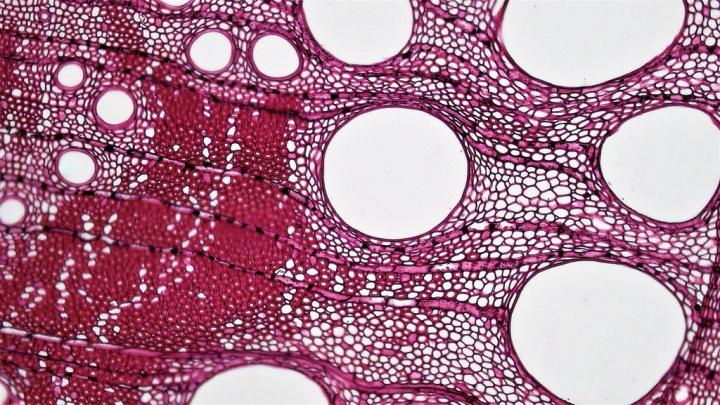

Credit: Berkshire Community College Bioscience Image Library

A new family of enzymes has been discovered which paves the way to convert plant waste into sustainable and high-value products such as nylon, plastics, chemicals, and fuels.

The discovery was led by members of the same UK-US enzyme engineering team which, in April, improved a plastic-digesting enzyme, a potential breakthrough for the recycling of plastic waste.(Kate to add LINK)

The study published in Nature Communications was led by Professor John McGeehan at the University of Portsmouth, Dr Gregg Beckham at the US Department of Energy's National Renewable Energy Laboratory (NREL), Professor Jen Dubois at Montana State University, and Professor Ken Houk at the University of California, Los Angeles.

The new family of enzymes are active on the building blocks of lignin – one of the main components of plants, which scientists have been trying for decades to find a way of breaking down efficiently.

Professor McGeehan, Director of the Institute of Biological and Biomedical Sciences in the School of Biological Sciences at Portsmouth, said: "We have assembled an international team for the discovery and engineering of naturally occurring enzymes. Enzymes are biological catalysts that can perform incredible reactions, breaking down some of our toughest natural and man-made polymers.

"To protect their sugar-containing cellulose, plants have evolved a fascinatingly complicated material called lignin that only a small selection of fungi and bacteria can tackle. However, lignin represents a vast potential source of sustainable chemicals, so if we can find a way to extract and use those building blocks, we can create great things."

Lignin acts as scaffolding in plants and is central to water-delivery. It provides strength and also defence against pathogens.

"It's an amazing material," Professor McGeehan said, "cellulose and lignin are among the most abundant biopolymers on earth. The success of plants is largely due to the clever mixture of these polymers to create lignocellulose, a material that is challenging to digest."

The research team found a way of releasing a key bottleneck in the process of breaking down lignin to its basic chemicals. The results provide a route to making new materials and chemicals such as nylon, bioplastics, and even carbon fibre, from what has previously been a waste product.

The discovery also offers additional environmental benefits – creating products from lignin reduces our reliance on oil to make everyday products and offers an attractive alternative to burning it, helping to reduce CO2 emissions.

The research team was made up of experts in biophysics, structural biology, synthetic biology quantum chemistry, biochemistry, and molecular dynamics at the University of Portsmouth and NREL, and at the US universities of Montana State, Georgia, and California and Brazil's University of Campinas.

Sam Mallinson, a PhD student in structural biology at the University of Portsmouth and first author on the paper said: "There is a long-standing phrase – you can make anything out of lignin except money – but by harnessing the power of enzymes, this is set to change. Using advanced techniques, from X-ray crystallography at the Diamond Light Source synchrotron, to advanced computer modelling, we have been able to understand the detailed workings of a brand new enzyme system."

The enzyme is a new class of cytochrome P450, and it is promiscuous, meaning it's able to work on a wide range of molecules.

Dr Beckham said: "This new cytochrome P450 enzyme can degrade a lot of different lignin-based substrates. That's good because it means it can then be engineered to be a specialist for a specific molecule and we can evolve it further to push it in a certain direction.

"We now have one of the most well-known, versatile, engineerable and evolvable classes of enzymes ready to go as a foothold for biotechnology to move forward and make the enzyme better."

The research comes on the heels of another study just published in the journal PNAS, led by Professor Ellen Neidle at the University of Georgia together with members of this team, which found a way of speeding up the evolution of this enzyme. The group are now working together to discover and evolve even faster enzymes for turning lignin into high-value sustainable products.

###

The research was jointly funded by the Biotechnology and Biological Sciences Research Council (BBSRC), National Science Foundation (NSF), and the DOE EERE Bioenergy Technologies Office. The 3D structures of the enzymes were solved at Diamond Light Source, the UK's national synchrotron science facility in Oxford.

Media Contact

Kate Daniell

[email protected]

44-239-284-3743

http://www.port.ac.uk

Related Journal Article

http://dx.doi.org/10.1038/s41467-018-04878-2