Resource-efficient, flexible, and low-cost production of fuel cells — State Ministry of Economic Affairs grants funding in the amount of about EUR 1 million

Credit: wbk, KIT

In five years’ time, it is planned to extend the EU climate goal of reducing CO2 emission of new vehicles by 37.5% until 2030 to heavy duty vehicles as well. Stricter goals are currently being discussed in the EU. In 2019, 409,801 commercial vehicles were registered in Germany, of these, 38,620 semitrailer trucks. So far, they have not been subject to any CO2 reduction requirements. Within the “KliMEA” project, researchers of Karlsruhe Institute of Technology (KIT) will now extensively study drive systems of heavy duty vehicles and fuel cell technology to find ways how future production of fuel cell components can be adapted to the new requirements.

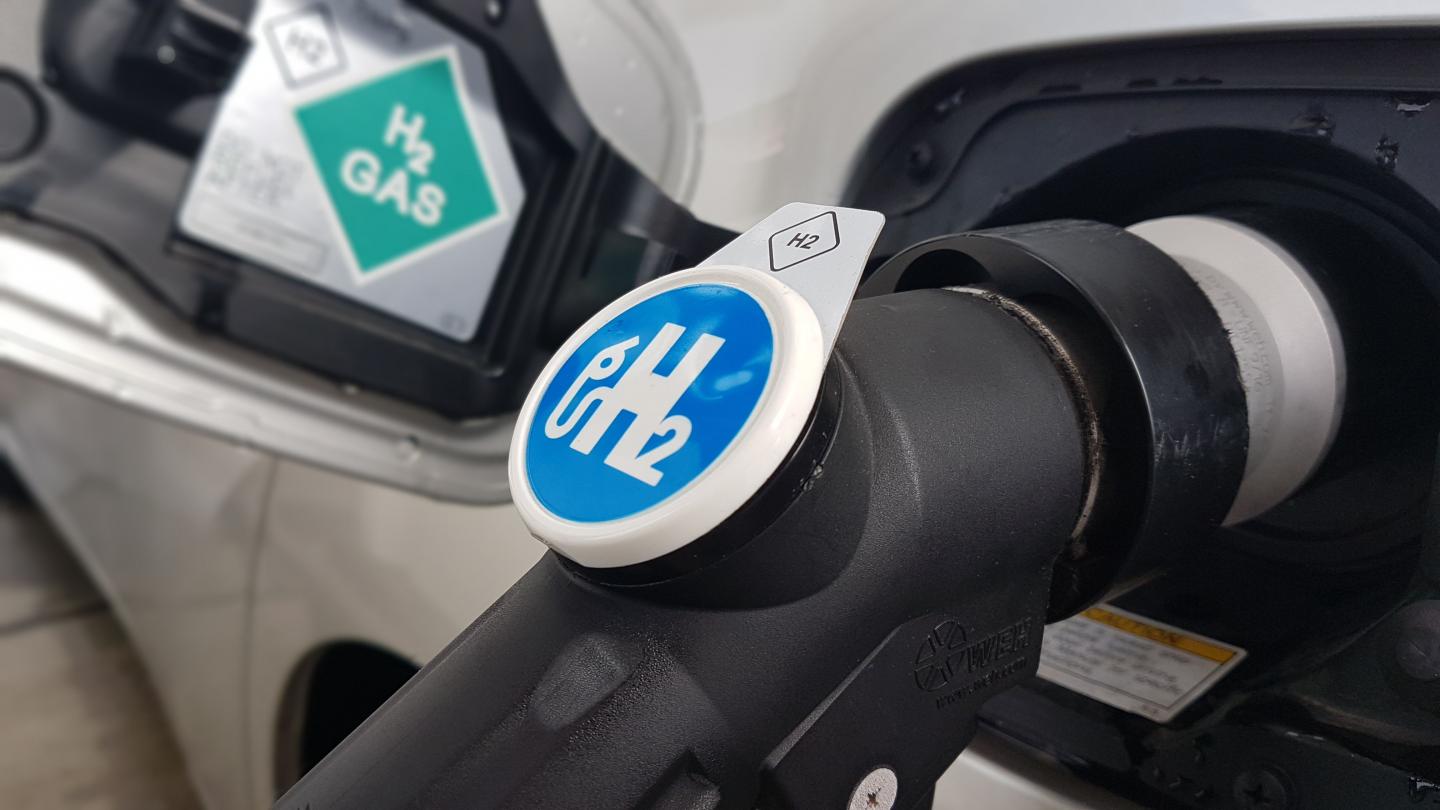

Fuel cell technology appears promising to reduce CO2 emissions of heavy duty vehicles by 15% until 2025 and 30% until 2030. Conventional truck powertrains with diesel engines already are largely optimized and offer little development potential. Battery electric drive solutions existing for private cars cannot be transferred directly, as the battery required would be too heavy and charging times would be too long.

“Apart from the use of synthetic fuels, we consider hydrogen to have a great potential for energy supply of commercial vehicles. First vehicles are already available. However, fuel cell development must be accelerated considerably for a planned introduction by 2025. The pace of fuel cell development will be set by production technology,” says Dr. Nicole Hoffmeister-Kraut, Baden-Württemberg Minister of Economic Affairs, Labor, and Housing.

The Membrane in the Fuel Cell Is of Decisive Importance

In a vehicle with fuel cells, a lightweight fuel cell system is sufficient, the required hydrogen can be refueled quickly. A crucial step of fuel cell production is manufacture of the membrane electrode assembly (MEA). The MEA is a composite component. Its core piece is the polymer electrolyte membrane (PEM). The PEM is just a few micrometers thin and changes considerably when moisture changes. This may cause damage, cracks or detachments, as a result of which the entire composite component can no longer be used. To prevent this, temperature of the production area must be controlled. “Installation of such a system requires a long planning horizon and is associated with high costs for both procurement and operation. Within our research project “KliMEA” we study ways to locally control the temperature of the MEA component by a so-called microenvironment. The PEM is placed under a type of bell jar to maintain the right climate and is then subjected to further processing,” says Professor Jürgen Fleischer, Head of KIT’s Institute of Production Science (wbk). “This process could make MEA production flexible as far as the numbers of pieces produced are concerned, it may accelerate production and, hence, reduce the consumption of resources and costs.”

###

About KliMEA: Goals and Partners

“KliMEA” is the German acronym of “climate-adaptive and model-based membrane electrode assembly manufacture.” Two wbk groups are involved in the project. As a project partner, the Thin Film Technologies (TFT) group of KIT studies moisture absorption by the PEM. This component considerably influences the behavior of the MEA. It becomes longer or shorter when air moisture changes. On this basis, a wbk team simulates the impacts of PEM changes on the MEA to obtain the required process knowledge. Using a “digital twin”, that is by means of a digital, close-to-reality, and sufficiently detailed simulation during operation, the second team of wbk studies connection to the real system and derives suitable measurement strategies. The data collected are needed for quality assurance and traceability. On this basis, it can be decided whether use of a certain assembly is associated with a risk and countermeasures have to be taken.

The associated project partner Daimler Truck Fuel Cell GmbH contributes its expert knowledge in the area of industrial MEA manufacture. e-mobil BW GmbH supports the project by making available its experience gained in the management of the Fuel Cell Cluster of Baden-Württemberg. Within the Strategy Dialog for the Automotive Sector in Baden-Württemberg, the State Ministry of Economic Affairs, Labor, and Housing funds the research project with about EUR 1 million until late 2021.

Melanie Klagmann, Öffentlichkeitsarbeit am wbk Institut für Produktionstechnik, Phone: +49 721 608-41173, melanie klagmann?kit edu

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 24,400 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

Media Contact

Monika Landgraf

[email protected]

Original Source

https:/