Stefan Wilhelm, an associate professor in the Stephenson School of Biomedical Engineering at the University of Oklahoma, and several students in his Biomedical Nano-Engineering Lab have recently published an article in the journal Nano Letters that outlines their recent important nanomedicine advancement.

Credit: Provided by the University of Oklahoma.

Stefan Wilhelm, an associate professor in the Stephenson School of Biomedical Engineering at the University of Oklahoma, and several students in his Biomedical Nano-Engineering Lab have recently published an article in the journal Nano Letters that outlines their recent important nanomedicine advancement.

The group examined how to create tools that produce nanomedicines, such as vaccine formulations, directly at the point of care. In doing so, the large centralized facilities, shipping challenges, and extreme cold storage challenges faced during the COVID-19 pandemic would no longer limit vaccine distribution.

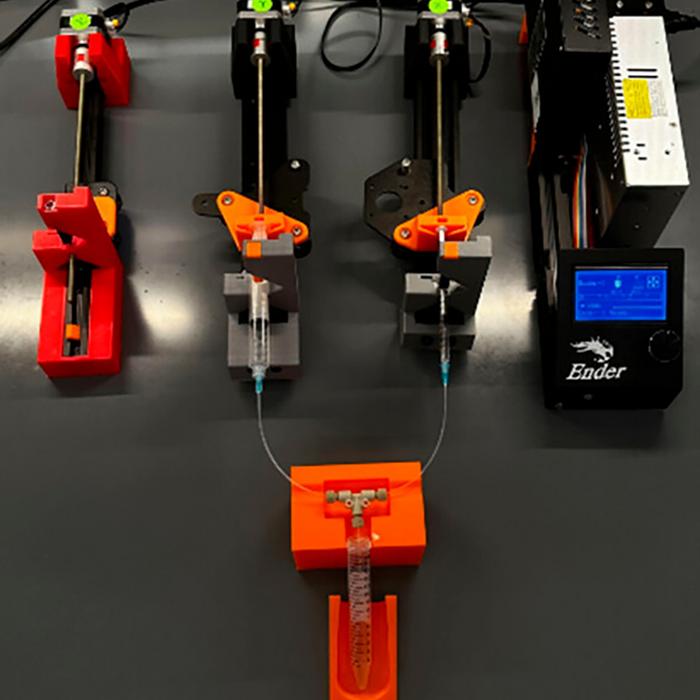

Wilhelm, with student researchers such as Hamilton Young, a senior biomedical engineering student, and Yuxin He, a biomedical engineering graduate research assistant, used 3D printer parts to mix fluid streams together containing the building blocks of nanomedicines and their payloads in a T-mixer format.

“This mixing device is essentially a T-shaped piece of tubing that forces two fluid streams to flow into each other, mixing nanomaterial and payload components together. Once mixed, the final product would exit through the other end,” Wilhelm said. “This mixing concept is used in industrial processes, so we wondered if we could make these devices as cost-efficient as possible.”

The team discovered a publication from a European research group that demonstrated that commercially available 3D printers could be reassembled into syringe pumps needed to push the fluids through the T-mixer device. Once built, they tried to produce nanomedicines with their 3D-built T-mixer.

“We were focusing on formulations that are used in the clinic, such as mRNA lipid nanoparticles, liposomes, and polymeric nanoparticles. One of the molecules we used was developed by a collaborator at OU Health Sciences to limit prostate cancer cell growth,” Wilhelm said. “We encapsulated this molecule into our nanomedicine formulations and showed that it actually stops those prostate cancer cells from growing.”

Based on this example, the team’s research has potentially broad implications for novel cancer therapies and vaccines against infectious diseases, as mRNA technology is already being used in clinical trials for personalized cancer vaccines.

“All of this mRNA technology relies on nanotechnology. mRNA molecules degrade too fast in the body to be effective without encapsulating them in nanoparticles,” Wilhelm said. “This process could open up a bright future for nanotechnology in medicine and will hopefully greatly improve healthcare.”

Wilhelm also foresees a future where doctors’ offices and clinics in rural communities with limited resources could use this technology to create personalized vaccines. His work with B4NANO, a partnership and outreach program with Native American tribes and communities in Oklahoma, inspires this goal.

“I could see a future situation where a patient walks into a doctor’s office with an infectious disease —possibly cancer. After a diagnosis by the doctor, a vaccine is produced at the doctor’s office in a manner similar to how single-serve coffee maker works – you just put in your capsules, press a button and get a personalized vaccine for that patient,” Wilhelm said. “Our goal is to develop this kind of benchtop device and then hopefully find industry partners to commercialize systems like these.”

Another goal Wilhelm has is training the next generation of biomedical engineers, like Young and He, to solve challenges in healthcare.

“The challenges we face in biomedical engineering require that we have a diverse team, with people coming from all different kinds of backgrounds. Everybody brings in their unique perspective, unique skill sets,” Wilhelm said. “My lab places a lot of emphasis on working with undergraduate students, even high school students, and bridging the gap from undergraduates to graduate students to postdocs. They learn from each other and learn to mentor each other.”

Learn more about the Wilhelm Biomedical Nano-Engineering Lab and read the article, “Toward the Scalable, Rapid, Reproducible, and Cost-Effective Synthesis of Personalized Nanomedicines at the Point of Care,” in Nano Letters, DOI no. 10.1021/acs.nanolett.3c04171.

Journal

Nano Letters

DOI

10.1021/acs.nanolett.3c04171

Article Title

Toward the Scalable, Rapid, Reproducible, and Cost-Effective Synthesis of Personalized Nanomedicines at the Point of Care

Article Publication Date

11-Jan-2024