Researchers at the Oak Ridge National Laboratory (ORNL), affiliated with the U.S. Department of Energy (DOE), have made groundbreaking advancements in carbon fiber technology by innovating a process that enhances the binding between carbon fibers and the surrounding polymer matrix. This development has the potential to significantly improve the performance of composite materials, which serve critical roles in industries such as automotive and aerospace where strength and lightweight characteristics are paramount.

The findings, released in the prestigious journal Advanced Functional Materials, reveal that carbon nanofibers can be employed to dramatically enhance the adhesion properties of carbon fiber-reinforced composites. This advancement is particularly significant, as it addresses a longstanding challenge within the industry: the weak interface bond between carbon fibers and the polymer matrix. By focusing on the inherent properties of carbon nanofibers, researchers have developed a hybrid approach that merges both chemical and mechanical bonding to achieve remarkable gains in tensile strength and toughness.

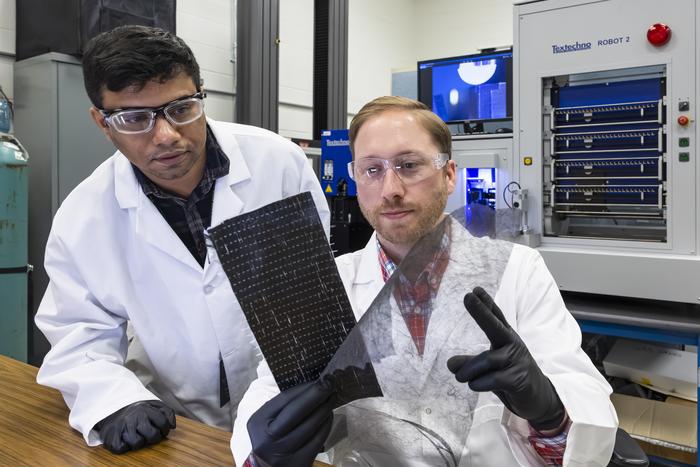

The lead researcher on the project, Sumit Gupta, highlighted the innovative nature of their technique, stating that it provided a dual solution—simultaneously optimizing the interface that typically limits the effectiveness of these materials. Gupta’s research team found that by integrating carbon nanofibers into the composite matrix, they created a system where the bonds formed not only adhered better but also created a physically stronger product, yielding a 50% improvement in tensile strength and nearly doubling the toughness of the composite material.

.adsslot_ahLF6r0CeS{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_ahLF6r0CeS{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_ahLF6r0CeS{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

The fundamental understanding of carbon fiber composites is similar to that of reinforced concrete; however, the challenge lies in improving the effectiveness of the adhesive between the two materials, which has often hindered advancements. Traditional methods attempted to remedy this by modifying the fiber surfaces or adding adhesion promoters with mixed results. The ORNL approach represents a novel method that actively combines nanotechnology with polymer science in a manner that is poised to revolutionize composite manufacturing processes.

Essential to this technique is a method known as electrospinning. This process enables the precise creation of extremely fine fibers from polyacrylonitrile, a common precursor for carbon fibers. These fibers, measuring about 200 nanometers in diameter, are then strategically placed within the composite structure, forming a robust network of connections between the carbon fibers and the surrounding polymer. The resulting structure creates what researchers refer to as “bridges” between the materials, enhancing the interdisciplinary performance attributes critical for various applications.

The ORNL researchers have leveraged advanced facilities, such as the Center for Nanophase Materials Sciences, to analyze these interactions and refine the methods used for developing this novel technique. Through advanced imaging and scattering techniques, they were able to gain insights at the nanoscopic level, elucidating how these fibers interact with the matrix and enabling them to fine-tune their electrospinning parameters for optimal results.

Further illustrating the innovative nature of their research, the team has tapped into one of the flagship supercomputers located at the Oak Ridge Leadership Computing Facility, providing them the computational power needed to model and simulate the interactions within these composite systems. This capability has facilitated a deeper understanding of how nanoscale fibers can improve adhesion and contribute to an overall enhancement in material properties, thus broadening the potential applications for composite materials.

Moving forward, the research team is actively pursuing industrial partnerships to commercialize their techniques, aiming to transform the carbon fiber landscape by making it more cost-effective and accessible. With the cost of carbon fiber being a critical barrier to widespread adoption, the hope is that by improving the bonding mechanisms, manufacturers can reduce the quantity required while still maintaining superior material performance. Furthermore, the innovation allows for the use of shorter, discontinuous fibers, which are typically seen as waste, thus promoting sustainability in composite materials production.

Initial inquiries into potential applications have revealed a wealth of opportunities outside traditional sectors. The team sees possibilities for reinforcing civil infrastructure or developing advanced composites for defense and security applications. This comprehensive vision underscores the versatility of the new techniques developed at ORNL and their potential impact on a variety of fields.

As they refine the electrospinning process, the research team at ORNL continues to explore even more possibilities, including integrating this technique with prior research focused on creating smart, self-sensing composites that can monitor their structural health using advanced materials. This hybrid of nanotechnology and materials engineering embodies the future of composite materials, positioning ORNL at the forefront of innovative materials science.

In essence, this research is not just about creating stronger materials; it represents a significant step towards realizing the full potential of carbon fiber composites in modern engineering and industrial applications. The ongoing collaboration between scientists and engineers will solidify the importance of such advancements in overcoming challenges in design and manufacturing processes across multiple sectors.

Furthermore, the impact of this research stretches beyond academic curiosity, contributing to the larger narrative of sustainable and efficient material usage in the face of growing energy demands and environmental challenges. As the ORNL team pushes the boundaries of knowledge and application, their findings will likely inspire future innovations in composite technologies that promise to reshape our built environment.

In conclusion, the work conducted by the Oak Ridge National Laboratory represents a vital leap forward in composite materials technology, with implications that could extend beyond current industrial practices, ushering in an era characterized by advanced, efficient, and more sustainable composite solutions.

Subject of Research: Enhancing the Binding in Carbon Fiber Composites

Article Title: Designing Physicochemically-Ordered Interphases for High-Performance Composites

News Publication Date: 1-May-2025

Web References: energy.gov/science

References: Advanced Functional Materials

Image Credits: Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

Keywords

Composite materials, Nanotechnology, Materials science

Tags: advanced functional materials researchaerospace carbon fiber advancementsautomotive composite materialscarbon fiber compositescarbon nanofibers applicationenhancing adhesion in compositeshybrid bonding techniqueslightweight composite durabilitynanofiber technology in compositesOak Ridge National Laboratory innovationspolymer matrix strengtheningtensile strength improvements