Recently, researchers from the Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences, led by Prof. TIAN Xingyou and Prof. ZHANG Xian, along with associate Prof. YANG Yanyu from the College of Materials Science and Engineering at Zhengzhou University, used gallium indium alloy (EGaIn) to initiate the polymerization and serve as flexible fillers to construct liquid metal/polyvinyl alcohol(PVA)/P(AAm-co-SMA) double network hydrogel.

Credit: LI XIaofei

Recently, researchers from the Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences, led by Prof. TIAN Xingyou and Prof. ZHANG Xian, along with associate Prof. YANG Yanyu from the College of Materials Science and Engineering at Zhengzhou University, used gallium indium alloy (EGaIn) to initiate the polymerization and serve as flexible fillers to construct liquid metal/polyvinyl alcohol(PVA)/P(AAm-co-SMA) double network hydrogel.

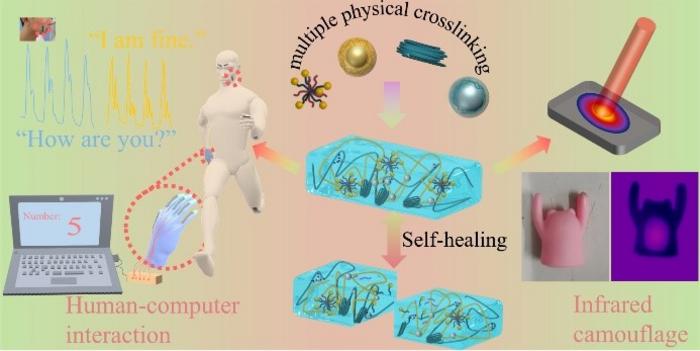

“The resulting material was super-stretchable and self-healing,” said LI Xiaofei, first author of the paper, “it will promote the research and practical application of hydrogels and liquid metal in intelligent devices and military fields.”

The study was published in Materials Horizons.

Most conductive hydrogels suffer from subpar mechanical qualities and lack desirable self-recovery and self-healing abilities, severely limiting hydrogels’ potential uses. Liquid metals like gallium indium alloy (EGaIn) can tougen polymers by conforming to their changing shapes. Also, gallium (Ga) in EGaIn can initiate vinyl monomer’s free radical polymerization.

In this research, the team built a liquid metal/PVA/P(AAm-co-SMA) double network hydrogel (LM hydrogel) with EGaIn serving as both the polymerization initiator and the flexible fillers.

The PVA network used PVA microcrystals and coordination interaction of Ga3+ and PVA as cross-links, while the P(AAm-co-SMA) network used hydrophobic association and the EGaIn microspheres. The LM hydrogel was endowed with excellent super-stretchability (2000%), toughness (3.00 MJ/m3), notch resistance, and self-healing property (> 99% at 25 °C after 24 h) due to the multiple physical cross-links and the synergistic effect of the rigid PVA microcrystal network and the ductile P(AAm-co-SMA) hydrophobic network.

“The sensors developed for it can be used in health monitoring and motion identification through human-computer interaction,” said LI Xiaofei, “thanks to the LM hydrogel’s sensitive strain sensing capability.”

As a result of EGaIn’s low infrared emissivity and remarkable photothermal, LM hydrogel shows considerable promise in infrared camouflage.

Journal

Materials Horizons