Multi-photon approaches provide printing rates of up to about ten million voxels per second. And, multi-photon-based 3D approaches structure matter with a resolution approaching sub-micrometer and nanometer feature sizes. Such spatial resolution is crucial for many applications in photonics and electronics and is inaccessible to most other 3D additive manufacturing approaches. However, the vast majority of 3D printed objects and devices made along these lines has been composed of only a single polymeric material. Multi-material architectures are much less investigated than single-material architectures, yet, most real-life systems (microscopic and macroscopic, biological and artificial) contain a large number of different materials with vastly dissimilar optical, mechanical, thermal, and electronic properties.

In a new paper published in Light: Advanced Manufacturing, a team of scientists, led by Professor Martin Wegener from Institute of Applied Physics, Karlsruhe Institute of Technology, Germany and co-workers have reviewed approaches and achievements on multi-material multi-photon micro/nano-printing. Existing materials that might serve as a working set of “primary materials” are concluded first. In the second step, processing dissimilar primary materials within 3D printed structures using a single machine tool is discussed. Corresponding literature are divided into two avenues.

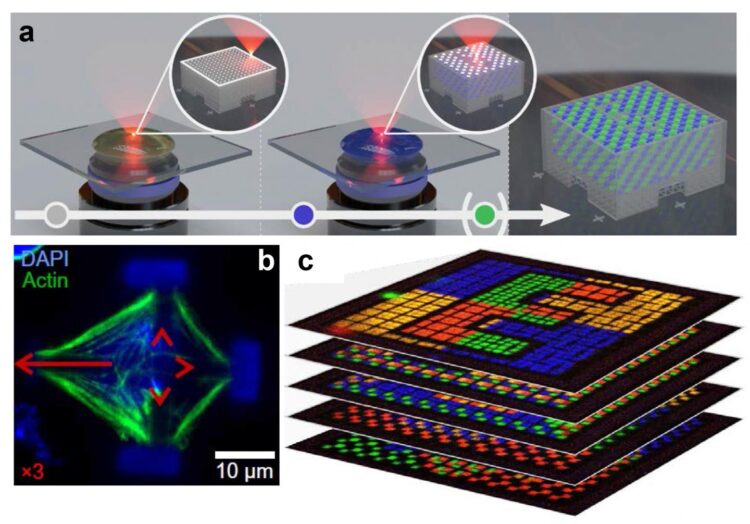

In the first avenue, different photoresists – the counterparts of the colored inks – are combined to manufacture a targeted multi-material 3D structure. So far, this combination has been accomplished by intermediate manual processing steps, but automated multi-photon multi-material 3D printing systems are rapidly developing.

In the second avenue, a single photoresist delivers 3D printed material with different properties. There is no direct analogue in graphical 2D printing. The underlying idea is to impose a stimulus during the 3D printing process of each voxel, influencing the photo-reaction of the ink, such, that the emerging material properties can be varied locally and deterministically in 3D.

“Nature proceeds quite similarly. It achieves a vast variety of different effective material properties in animals and plants by architecting on a micrometer and nanometer scale by using only a limited number of building blocks, based on polysaccharides, proteins, and minerals.16 Printing tailored 3D microstructures results in artificial composites, with effective optical, mechanical, thermal, and electronic properties that can be qualitatively dramatically distinct from those of the constituents. As for dithering in 2D, it is key that the characteristic feature sizes are sufficiently small such that the observer does not notice them and rather experiences an effective homogeneous continuum” they added.

“Concerning primary materials, the field still shows shortcomings concerning electrically conductive, semiconducting, metallic, and stimuli-responsive ingredients. ” the scientists forecast.

###

Media Contact

Liang Yang

[email protected]

Related Journal Article

http://dx.