An interdisciplinary research team at Pohang University of Science and Technology (POSTECH) has made significant strides in the realm of clean hydrogen production through an innovative approach to microwave-assisted thermochemical methods. This groundbreaking technology addresses longstanding challenges that have impeded the effective and sustainable generation of hydrogen—a crucial element in the transition away from fossil fuels and toward cleaner energy sources. Their research sheds light on the mechanisms involved in this novel process, potentially changing the landscape of hydrogen production and paving the way for broader applications.

As global energy needs continue to evolve, clean hydrogen has emerged as a particularly promising solution due to its zero carbon emissions when utilized as a fuel. Despite its potential, current hydrogen production technologies face serious barriers, primarily linked to conventional thermochemical methods. These methods often require temperatures exceeding 1,500°C, a significant drawback that makes them both energy-intensive and costly. Additionally, the high temperatures required pose challenges in scaling production, limiting practical applications in various industries.

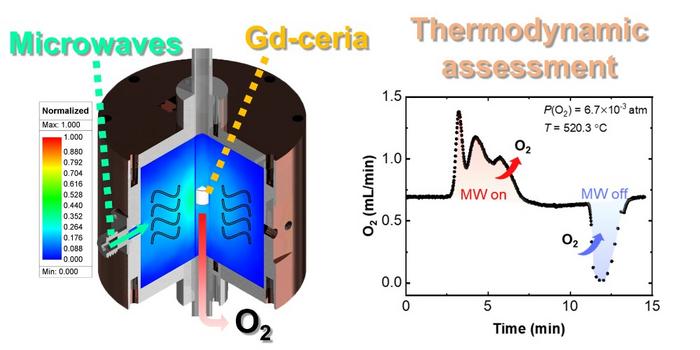

In light of these challenges, the POSTECH research team, led by Professor Gunsu S. Yun and supported by doctoral candidates from the Department of Physics and Mechanical Engineering, turned their focus toward microwave energy—an energy source that is widely used in household settings but rarely explored in industrial chemical processes. By leveraging microwave radiation, the researchers discovered that they could dramatically lower the required reduction temperature for gadolinium-doped ceria (CeO2)—a benchmark material used in hydrogen production. The team managed to reduce the temperature requirement to below 600°C, effectively slashing the traditional energy input by more than 60 percent.

One of the most remarkable findings of the POSTECH study is the ability of microwave energy to supplant a substantial portion of the thermal energy typically required for thermochemical reactions. This means that instead of relying solely on high temperatures to drive the chemical processes, microwave energy can replace up to 75 percent of the thermal input, creating a more energy-efficient and cost-effective approach to hydrogen production.

Beyond the temperature reductions, the research team achieved advancements in creating “oxygen vacancies” within the ceria material. These vacancies, which act as critical defects in the material’s structure, are essential for the reaction that splits water molecules into hydrogen and oxygen. Conventional methods often require prolonged periods at high temperatures to induce the formation of these vacancies. However, the POSTECH team successfully created them within minutes at temperatures significantly lower than what was previously achievable, opening doors to new efficiencies and productivities in hydrogen production processes.

The team’s findings were corroborated and further validated by a sophisticated thermodynamic model that provided insight into the underlying principles driving microwave-assisted reactions. This model not only supports the team’s experimental results but also helps in mapping the kinetics of the hydrogen production process, revealing the potential for process optimization and scaling in practical applications.

Professors Jin and Yun expressed a forward-looking vision for their research. They indicated that this innovation could significantly enhance the commercial viability of thermochemical hydrogen production technologies, encouraging further exploration into optimizing materials specifically designed for microwave-driven chemical processes. This research exemplifies the type of interdisciplinary collaboration that can lead to breakthroughs, as evidenced by the diverse expertise present within the POSTECH research team.

With the backing of several funding organizations, including the Circle Foundation’s Innovative Science and Technology Program, the Ministry of Science and ICT, and POSTECH’s Basic Science Research Institute, the researchers are well-positioned to continue their exploration into microwaves applications in sustainable energy. Their core aim remains clear: to drive a transition to cleaner and more efficient energy systems that can help combat climate change and reduce dependence on fossil fuels.

Overall, this study not only provides valuable insights into hydrogen production using microwaves but also highlights the potential for innovative solutions to emerge from the ongoing collaboration between various scientific fields. The implications of this research extend far beyond academic advancement; it holds promise for real-world applications that could facilitate a significant shift toward more sustainable energy practices. As energy demands increase and the consequences of climate change become more pronounced, technological advancements like this research effort at POSTECH are crucial for developing solutions that can meet future energy needs without jeopardizing the planet.

The POSTECH researchers are engaging with the scientific community to further disseminate their findings, indicating the importance of transparency and collaboration in addressing global energy challenges. By sharing their data and methodologies, they hope to inspire further investigation into microwave technologies and their potential applications across different materials and reactions.

In conclusion, the POSTECH team’s work demonstrates the transformative potential of innovative methods in the landscape of renewable energy technologies. As we strive for a sustainable future, advancing hydrogen production technologies like those developed at POSTECH can play an instrumental role in unlocking new pathways to clean energy solutions that can ultimately benefit humanity as a whole.

Subject of Research: Microwave-assisted thermochemical hydrogen production

Article Title: Thermodynamic assessment of Gd-doped CeO2 for microwave-assisted thermochemical reduction

News Publication Date: 5-Nov-2024

Web References: Journal of Materials Chemistry A

References: N/A

Image Credits: Credit: POSTECH

Keywords

Microwave energy, hydrogen production, thermal energy, oxygen vacancies, sustainable energy, thermochemical processes, ceria, clean hydrogen, energy efficiency, interdisciplinary research, environmental sustainability, scientific collaboration.

Tags: Ceria-based materialsClean energy innovationClimate Change MitigationEnergy-efficient processesgreen chemistryInterdisciplinary energy researchMicrowave technologyMicrowave-assisted hydrogen productionOxygen vacancy engineeringRenewable energy solutionsSustainable hydrogenThermochemical reduction