Although just cute little creatures at first glance, the microscopic geckos and octopuses fabricated by 3D laser printing in the molecular engineering labs at Heidelberg University could open up new opportunities in fields such as microrobotics or biomedicine. The printed microstructures are made from novel materials – known as smart polymers – whose size and mechanical properties can be tuned on demand and with high precision. These “life-like” 3D microstructures were developed in the framework of the “3D Matter Made to Order” (3DMM2O) Cluster of Excellence, a collaboration between Ruperto Carola and the Karlsruhe Institute of Technology (KIT).

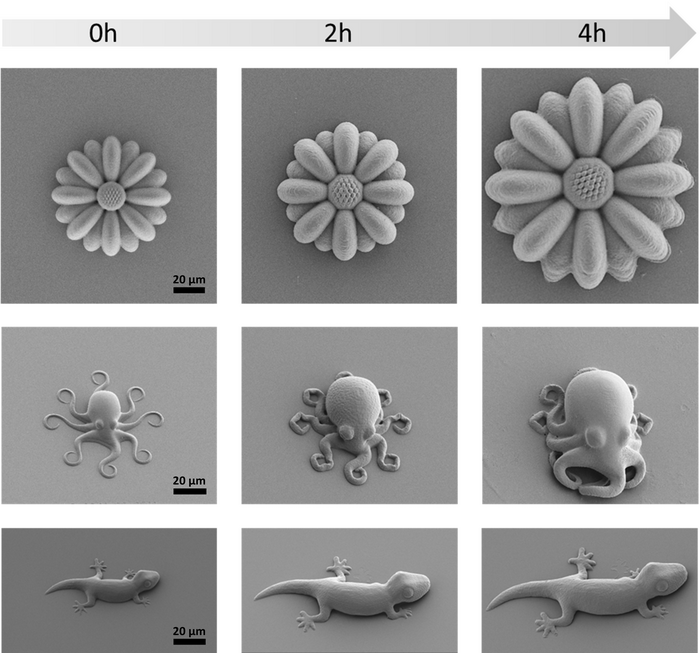

Credit: Christoph Spiegel (Heidelberg University). Adapted from Y. Jia et. al, Adv. Funct. Mater. 2022, 2207826 (CC BY 4.0)

Although just cute little creatures at first glance, the microscopic geckos and octopuses fabricated by 3D laser printing in the molecular engineering labs at Heidelberg University could open up new opportunities in fields such as microrobotics or biomedicine. The printed microstructures are made from novel materials – known as smart polymers – whose size and mechanical properties can be tuned on demand and with high precision. These “life-like” 3D microstructures were developed in the framework of the “3D Matter Made to Order” (3DMM2O) Cluster of Excellence, a collaboration between Ruperto Carola and the Karlsruhe Institute of Technology (KIT).

“Manufacturing programmable materials whose mechanical properties can be adapted on demand is highly desired for many applications,” states Junior Professor Dr Eva Blasco, group leader at the Institute of Organic Chemistry and the Institute for Molecular Systems Engineering and Advanced Materials of Heidelberg University. This concept is known as 4D printing, and the additional fourth dimension refers to the ability of three-dimensionally printed objects to alter their properties over time. One prominent example of materials for 4D printing are shape memory polymers – smart materials that can return to their original shape from a deformed state in response to an external stimulus such as temperature.

The team led by Prof. Blasco recently introduced one of the first examples of 3D printed shape memory polymers at the microscale. In cooperation with the working group of biophysicist Prof. Dr Joachim Spatz, a scientist at Ruperto Carola and Director at the Max Planck Institute for Medical Research, the researchers developed a new shape memory material that can be 3D printed with high resolution both at the macro and at the microscale. The structures produced include box-shaped microarchitectures whose lids close in response to heat and can then be reopened. “These tiny structures show unusual shape memory properties at low activation temperatures, which is extremely interesting for bioapplications,” explains Christoph Spiegel, a doctoral researcher in the working group of Eva Blasco.

Using adaptive materials, the researchers succeeded in a follow-up study in producing much more complex 3D microstructures like geckos, octopuses, and even sunflowers with “life-like” properties. These materials are based on dynamic chemical bonds. The Heidelberg researchers report that alkoxyamines are particularly suitable for this purpose. After the printing process, these dynamic bonds allow for the complex, micrometric structures to grow eight-fold in just a few hours and to harden, while maintaining their shape. “Conventional inks do not offer such features,” emphasises Prof. Blasco. “Adaptive materials containing dynamic bonds have a bright future in the field of 3D printing,” adds the chemist.

Materials scientists at the Karlsruhe Institute of Technology (KIT) also participated in the research on adaptable materials with “life-like” properties. The German Research Foundation and the Carl Zeiss Foundation funded the work, which was carried out within the framework of the 3DMM2O Cluster of Excellence. The results were published in two papers in the journal “Advanced Functional Materials”.

Original publications:

C.A. Spiegel, M. Hackner, V.P. Bothe, J.P. Spatz, E. Blasco: 4D Printing of Shape Memory Polymers: From Macro to Micro. Advanced Functional Materials (6 February 2022), https://doi.org/10.1002/adfm.202110580

Y. Jia, C.A. Spiegel, A. Welle, S. Heißler, E. Sedghamiz, M. Liu, W. Wenzel, M. Hackner, J.P. Spatz, M. Tsotsalas, E. Blasco: Covalent Adaptable Microstructures via Combining Two-Photon Laser Printing and Alkoxyamine Chemistry: Toward Living 3D Microstructures. Advanced Functional Materials (22 September 2022), https://doi.org/10.1002/adfm.202207826

Journal

Advanced Functional Materials

DOI

10.1002/adfm.202207826

Article Title

Covalent Adaptable Microstructures via Combining Two-Photon Laser Printing and Alkoxyamine Chemistry: Toward Living 3D Microstructures

Article Publication Date

22-Sep-2022