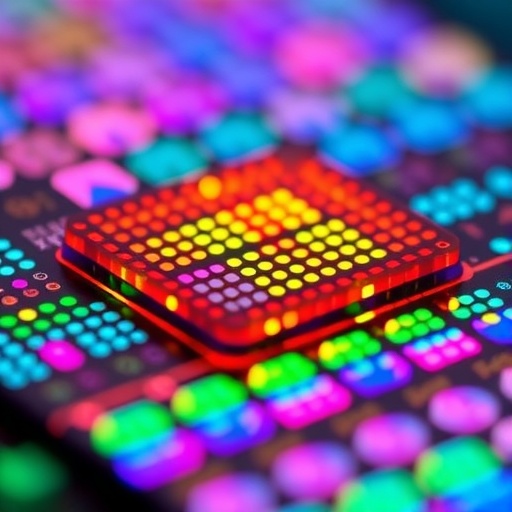

In a breakthrough that could revolutionize the fabrication of organic light-emitting diodes (OLEDs), a team of researchers has unveiled a novel micrometer-scale indirect photopatterning technique to precisely engineer red, green, and blue (RGB) OLED emissive layers within a single-phase network structure. This advancement heralds a significant leap forward in display technology, promising higher resolution, improved color purity, and streamlined manufacturing processes for next-generation OLED screens.

OLED technology has long been celebrated for its vibrant colors, flexibility, and energy efficiency, finding applications in everything from smartphones to large-format televisions. However, one persistent challenge has been the precise patterning of distinct RGB emissive layers at micrometer scales without damaging underlying materials or compromising performance. Traditional photolithographic techniques often involve multiple processing steps and can introduce defects or cross-contamination, limiting pixel density and overall device quality.

Addressing these limitations, the newly developed indirect photopatterning approach circumvents the need for direct exposure of the emissive layers to harmful photolithographic conditions. Instead, this method leverages a sophisticated single-phase polymer network that serves as a scaffold for the OLED materials. By exploiting subtle photochemical reactions within this network, the team successfully patterned RGB emissive layers with micrometer precision, achieving intricate, well-defined pixel structures without degrading the organic compounds.

.adsslot_Bcj8I6GMzl{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_Bcj8I6GMzl{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_Bcj8I6GMzl{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

The core innovation lies in the design of the single-phase network architecture, which combines cross-linkable polymer matrices with emissive organic molecules, enabling spatially selective activation in response to controlled light exposure. This design ensures that only targeted regions undergo photochemical transformation, effectively “writing” the desired patterns with high fidelity. The researchers optimized parameters such as wavelength, intensity, and exposure duration to finely tune the photopatterning process for each RGB component.

One of the remarkable benefits of this indirect photopatterning technique is its compatibility with existing solution-processing methods commonly used in OLED fabrication. By integrating seamlessly into current manufacturing workflows, this method reduces complexity and cost, potentially accelerating the adoption of microstructured OLED displays in commercial products. Moreover, the approach facilitates ultrahigh-resolution pixel arrays, which are essential for emerging applications like augmented reality (AR) and virtual reality (VR) devices demanding superb visual clarity.

Beyond resolution enhancements, the technique also improves the uniformity and stability of the emissive layers. The single-phase network architecture mitigates phase separation and aggregation of emissive molecules, which are typically detrimental to device longevity and color accuracy. This structural integrity translates into OLEDs that not only look better but maintain consistent performance over extended operating periods.

In-depth characterization of the fabricated OLED layers revealed outstanding electroluminescent properties, with sharp emission spectra closely matching the target RGB colors. The researchers conducted extensive testing under various electrical and optical conditions, confirming that the indirect photopatterning process did not introduce adverse side effects such as increased surface roughness or unwanted chemical residues. These findings underscore the method’s robustness and reproducibility.

Importantly, the study demonstrates scalability potential, showcasing patterning over large substrate areas without loss of resolution or functional quality. This is a critical factor for industrial adoption, as large-scale display manufacturing demands uniform performance across expansive surfaces. The ability to pattern complex RGB arrays efficiently could pave the way for flexible, foldable, and transparent OLED displays with unprecedented pixel densities.

The implications of this technology extend beyond consumer electronics. High-precision photopatterning of OLED layers could enable novel optoelectronic devices, including advanced sensors, biointerfaces, and integrated photonic circuits. By controlling emissive regions with micrometer accuracy, researchers can tailor light emission profiles for specialized functions, enhancing device versatility and functionality.

Future research directions suggested by the team include refining the polymer network chemistry to further enhance photopatterning resolution and exploring its applicability to other organic semiconductors and hybrid materials. There is also interest in combining this technique with complementary patterning strategies, such as inkjet printing and laser writing, to develop hybrid fabrication processes that leverage the strengths of multiple methods.

The study’s authors emphasize that their indirect photopatterning strategy not only addresses technical hurdles but also aligns with broader sustainability goals by reducing material wastage and energy consumption during manufacturing. The streamlined, fewer-step process minimizes chemical usage and eliminates harsh processing conditions, making it environmentally more benign than traditional methods.

In conclusion, the successful demonstration of micrometer-scale indirect photopatterning in single-phase RGB OLED emissive layers marks a pivotal milestone in optoelectronic fabrication. By enabling precise, high-resolution patterning without compromising material integrity or manufacturing efficiency, this approach opens exciting pathways for the future of OLED technology and its myriad applications across diverse technological landscapes.

Subject of Research: OLED emissive layer photopatterning in single-phase network structures for RGB displays.

Article Title: Micrometer-scale indirect photopatterning of RGB OLED emissive layers in single phase network structure.

Article References:

Lee, S., Ham, H., Ameen, S. et al. Micrometer-scale indirect photopatterning of RGB OLED emissive layers in single phase network structure. Light Sci Appl 14, 247 (2025). https://doi.org/10.1038/s41377-025-01907-w

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s41377-025-01907-w

Tags: advancements in display technologychallenges in OLED layer patterningenergy-efficient organic light-emitting diodeshigh-resolution OLED screensimprovements in color purity for displaysindirect photopatterning for OLEDsmicrometer-scale emissive layer engineeringmicroscale photopatterning techniquesnext-generation OLED manufacturing processesphotolithography alternatives for OLEDsRGB OLED fabrication methodssophisticated polymer networks in OLEDs