Credit: (c) Nicole Matschiavelli

The Federal Ministry of Education and Research (BMBF) is funding the research consortium with a grant of more than two million euros.

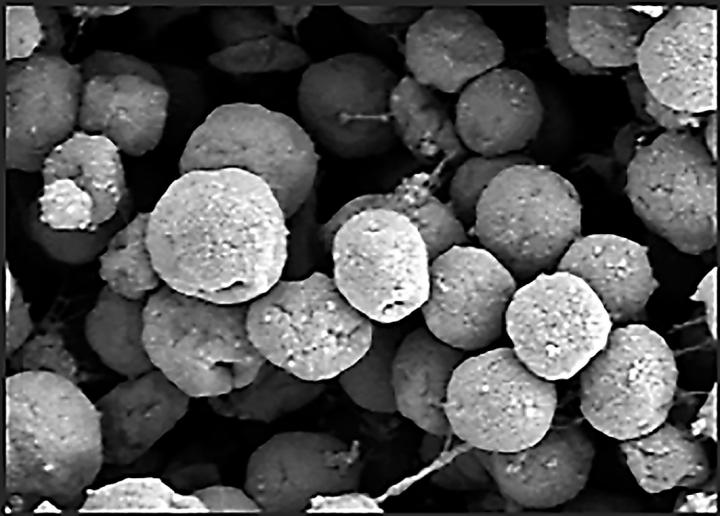

The Science Year 2020 has its focus on Bioeconomy with the aim of communicating state-of-the-art research on bio-based technologies and the associated concepts for a more sustainable economy to a broad public. With the new Science Year just having started, the Faculty of Biology at TU Dresden received the approval of a promising, large-scale bio-economic project in mid-January. Project coordinator Professor Michael Rother is delighted and eager to start researching and operating the small methanogenic eco-factories: “Methanogens, which are methanogenic microbes from the domain Archaea, have so far “only” been industrially applied as efficient biogas producers. With MethanoPEP we want to develop a broader application for them in sustainable production processes”.

The biological formation of methane (methanogenesis) is considered one of the oldest known metabolic processes, playing an essential role in the global carbon cycle. Methane, the end product of methanogenic metabolism, has become a highly attractive renewable energy source because it can be produced comparatively easily from biomass and can easily be distributed and stored in the existing natural gas grid.

However, in addition to their methane production capacity, the small power plants harbour unexplored metabolic capabilities that represent interesting resources for biotechnological applications.

Through synergetic cooperation, the project partners will strive to advance the expertise on methanogens through fundamental and applied research in three areas. The overall goal is to make the small power plants more robust, more versatile and universally applicable: The first field is the development of new and the optimisation of current cultivation principles. For example, the potential of electroactive methanogens in microbial electrosynthesis has barely been investigated so far. The second field covers the development of new and the advancement of current methods for the genetic manipulation of methanogens. Currently, Methanothermobacter, the only methanogen industrially employed in pure culture, is not genetically accessible at all. The third field is the expansion of the application potential of methanogens beyond methane production. By modifying their endogenous metabolism, the eco-factories are to produce value-added compounds, such as isoprenoids, beside methane. Isoprenoids are the largest class of natural products and are used in all areas of life, for example in pharmaceuticals, flavours, fragrances and plastics.

“The fact that the methanogens investigated by MethanoPEP only require water, salts, carbon dioxide and a (renewable) source of electrons promises to make the production competitive, even if initially the products only occur in small amounts. The biosynthesis of isoprenoids is proposed as proof of concept in MethanoPEP, but in principle, metabolic engineering could be used to produce any metabolite derived from acetyl-coenzyme A from methanogens,” said Prof. Rother explaining the huge potential of the small eco-factories.

###

Media Contact

Dr. Michael Rother

[email protected]

49-351-463-42611