In the ever-evolving landscape of catalysis, the drive to develop more efficient, selective, and sustainable catalytic systems has captured the interest of chemists and materials scientists worldwide. Central to many catalytic processes, particularly hydrogenation and dehydrogenation reactions, are metal–sulfur active sites. These specialized sites are instrumental in facilitating bond activation and transformation of molecules under milder conditions and with greater specificity than many traditional catalysts. However, conventional metal–sulfur catalysts often suffer from constraints rooted in their morphology: the most catalytically relevant active sites tend to reside predominantly on particle surfaces or along edges where accessibility is limited, curtailing the overall catalytic efficiency. Addressing these limitations necessitates innovative approaches to integrate such active sites more uniformly and deeply within a catalyst framework.

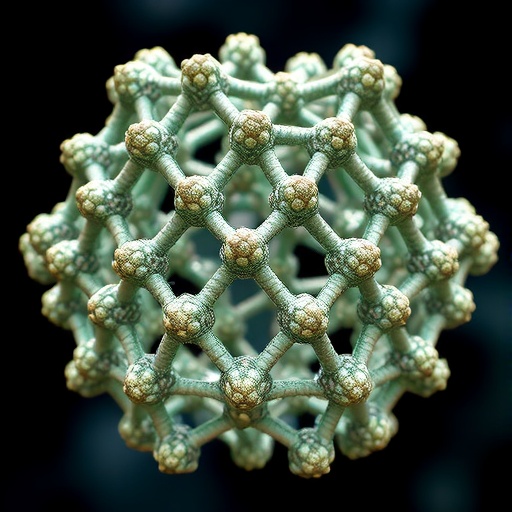

A pioneering study now unfolds this challenge through the integration of metal–sulfur active sites directly into the architecture of metal–organic frameworks (MOFs), crystalline materials known for their tunable porosity, modular construction, and extraordinary surface areas. This breakthrough leverages a meticulous post-synthetic modification approach that transforms bridging or terminal chloride ligands within the MOFs into hydroxide groups and subsequently into sulfide functionalities. The profound versatility of MOFs, combined with this strategic chemical conversion, permits the creation of robust materials featuring distributed, accessible metal–sulfur centers within their internal framework—a feat that elegantly overcomes the accessibility limitations of conventional catalysts.

The researchers meticulously selected two representative families of MOFs to demonstrate the robustness and generalizability of their approach. The first family is characterized by one-dimensional metal–chloride chains extended throughout the crystalline lattice, while the second is composed of discrete multinuclear metal clusters. This selection underscores the adaptability of their post-synthetic modification method to varied coordination environments and topologies within MOFs. The process begins with the substitution of chlorides with hydroxide groups, which serve as convenient precursors for further transformation. Following this hydroxide installation, a carefully controlled sulfurization step replaces the hydroxides with sulfide groups, thereby embedding functional metal–sulfur sites into the MOF backbone without compromising the material’s structural integrity.

.adsslot_8uJ2zUod5h{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_8uJ2zUod5h{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_8uJ2zUod5h{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

Advanced crystallographic studies, coupled with an array of spectroscopic techniques, provide a comprehensive insight into the structural evolution and chemical transformations underpinning this synthetic route. Single-crystal X-ray diffraction and powder X-ray diffraction (PXRD) analyses confirm that the crystallinity and long-range order of the MOF hosts remain largely preserved throughout the modification process. Moreover, spectroscopic signatures derived from X-ray photoelectron spectroscopy (XPS) and infrared spectroscopy distinctly verify the successful incorporation of sulfide moieties and the concomitant disappearance of chloride and hydroxide ligands. This rigorous characterization suite not only validates the chemical conversions but also reveals the precise chemical environments of metal centers after sulfur incorporation.

From an application standpoint, these sulfided MOFs exhibit enhanced catalytic performance in the selective hydrogenation of nitroarenes using molecular hydrogen—a reaction of paramount importance in synthetic chemistry and industrial processes. Typically, hydrogenation of nitroarenes demands catalysts capable of activating molecular hydrogen efficiently while ensuring high selectivity towards the formation of anilines rather than over-reduced or partially reduced by-products. The MOFs with embedded metal–sulfur sites demonstrate superior activity and selectivity, outperforming their chloride- or hydroxide-containing counterparts. This enhancement is attributed to the intrinsic properties conferred by the metal–sulfur bonding, which fundamentally alters the electronic and geometric landscape at the active sites.

To unravel the mechanistic underpinnings driving this catalytic enhancement, density functional theory (DFT) calculations were employed to probe the effects of sulfur incorporation on metal–ligand interactions and hydrogen activation pathways. These computations reveal a pronounced promotion of homolytic cleavage of the metal–ligand bonds upon sulfur incorporation, facilitating the generation of reactive metal-hydride intermediates essential for effective hydrogenation. The sulfur ligands not only stabilize key catalytic intermediates but also tune the electronic properties of the metal centers, lowering activation barriers for H2 dissociation while steering the reaction pathway towards the desired product with minimal side reactions.

The convergence of experimental evidence and theoretical insights positions this work at the forefront of rational catalyst design. It establishes a versatile platform for constructing MOFs embedded with accessible metal–sulfide active sites, offering new avenues to tailor catalytic properties through precise chemical manipulation of ligand environments. Such embedded active sites contrast sharply with traditional catalysts where activities are confined to surface-exposed sites, unlocking higher utilization efficiencies and paving the way for catalysts with enhanced durability and recyclability.

Furthermore, the method’s adaptability across different MOF structures heralds broad implications for catalysis beyond hydrogenation. The concept of post-synthetically converting labile peripheral ligands to catalytically relevant functionalities opens a frontier for the design of MOFs for myriad transformations, including electrocatalytic and photocatalytic processes where metal–sulfur sites are known to be impactful. It also contributes to bridging the divide between molecular and heterogeneous catalysis by combining the structural precision and tailorability of molecular catalysts with the robustness and scalability of solid-state materials.

Looking ahead, this strategy sparks intriguing opportunities to engineer MOF-based catalysts with synergetic active sites, integrating multiple types of ligands and metal centers within a single crystalline matrix to achieve multi-step catalysis or tandem reactions. The fine control over active site chemical identity and spatial arrangement afforded by post-synthetic modification is a potent tool in the chemist’s arsenal, facilitating the exploration of structure–property relationships in catalysis that could revolutionize the production of pharmaceuticals, fine chemicals, and sustainable fuels.

In a broader scientific context, the results underscore the power of combining advanced synthetic techniques, state-of-the-art characterization, and theoretical modeling to solve longstanding challenges in materials chemistry. By demonstrating that post-synthetic modification can be exploited to embed functional active sites within existing framework materials without sacrificing crystalline order, this approach redefines what is possible in the design and deployment of next-generation catalytic materials.

The ramifications of this work extend beyond catalysis, potentially influencing the design of sensors, energy storage materials, and substrates for gas capture and separation, where precise control over ligand composition and metal coordination environments dictate functional performance. The created metal–sulfur motifs serve as a tangible example of how atomic-level modifications can translate into macroscale benefits, inspiring the development of tailored materials that marry function, stability, and accessibility.

Ultimately, this research breathes new life into the field of metal–organic frameworks, transforming them from passive hosts or supports into active participants engineered at the atomic level for optimized catalytic outcomes. As industries increasingly demand catalysts that are not only efficient and selective but also sustainable and recyclable, approaches like this will be instrumental in shaping the future of green chemistry and chemical manufacturing.

Bridging fundamental science and practical applications, this advancement underscores a paradigm shift in catalyst design philosophy—eschewing reliance solely on surface phenomena in favor of architecting active sites that permeate the entire volume of a material. The in-depth structural control and tunability provided by MOFs, enriched through post-synthetic functionalization, carve a promising path to next-generation catalysts that are smarter, more specialized, and more impactful.

Subject of Research: Development of metal–sulfur active sites embedded in metal–organic frameworks (MOFs) via post-synthetic modification for enhanced catalytic hydrogenation.

Article Title: Introducing metal–sulfur active sites in metal–organic frameworks via post-synthetic modification for hydrogenation catalysis.

Article References:

Xie, H., Khoshooei, M.A., Mandal, M. et al. Introducing metal–sulfur active sites in metal–organic frameworks via post-synthetic modification for hydrogenation catalysis. Nat. Chem. (2025). https://doi.org/10.1038/s41557-025-01876-y

Image Credits: AI Generated

Tags: advanced materials for catalysisbond activation in catalysiscatalytic efficiency improvementsinnovative catalyst designmetal-organic frameworks applicationsmetal-sulfur active sitesMOF hydrogenation catalysisovercoming limitations of traditional catalystspost-synthetic modification techniquesselective hydrogenation reactionssustainable catalytic systemstunable porosity in MOFs