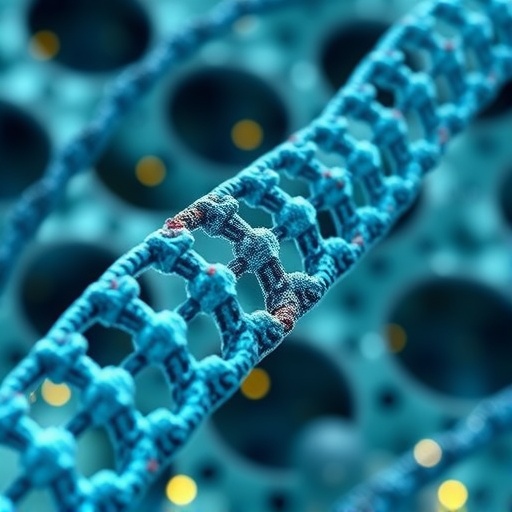

In a groundbreaking advancement that promises to redefine the landscape of synthetic biology and genetic engineering, a team of researchers has unveiled a novel, massively parallel DNA synthesis system based on microchip technology. Traditional high-throughput DNA synthesis techniques, while capable of producing vast arrays of synthetic oligonucleotides, have long been impeded by constraints such as low product concentration and cumbersome downstream processes. These limitations have presented significant barriers to the efficient assembly of long DNA sequences, restricting the scalability and practical application of synthetic gene construction. The newly devised system introduces a transformative ‘identification–sorting–synthesis–recycling’ iteration mechanism that not only exponentially amplifies DNA product concentrations but also streamlines the post-synthesis workflow, marking a pivotal step toward scalable and accessible gene synthesis.

Current DNA synthesis methodologies predominantly rely on intricate chip designs and microfluidic systems to enable the parallel production of thousands to millions of oligonucleotide sequences. However, these systems typically yield products at extremely low concentrations, often in the picomolar to nanomolar range, which necessitates additional concentration steps before the sequences can be effectively utilized for long DNA assembly or further molecular biology applications. This dilution challenge inherently complicates downstream processes such as polymerase chain reaction (PCR) amplification, ligation, and the construction of complex gene libraries, ultimately curtailing throughput and increasing time and resource investments.

The innovative framework reported by Zhang, Jiang, Wang, and their collaborators presents a marked departure from these traditional systems. Central to their approach is an iterative cycle combining the processes of identification, sorting, synthesis, and recycling within the microchip environment itself. By integrating these stages into a cohesive, self-contained workflow, the researchers have been able to surmount the dilution bottleneck and enhance the effective concentration of the DNA products by an astonishing four to six orders of magnitude. This leap in concentration not only enhances the feasibility of assembling longer DNA constructs but also reduces the need for complex purification and amplification steps downstream.

The identification phase of the system enables precise tracking of individual oligonucleotide sequences synthesized on the microchip. This is crucial because it allows for the spatial and molecular sorting of sequences based on their unique identifiers, thereby ensuring that only the desired molecules are selected for synthesis and subsequent processing. It is this level of high-resolution sequence management that underpins the system’s ability to separate and concentrate target DNA strands effectively from a complex mixture.

Following identification, the sorting mechanism isolates the correctly synthesized DNA oligonucleotides. This distinction is vital because synthesis errors and incomplete sequences are common pitfalls in high-throughput DNA synthesis, potentially compromising the integrity of downstream assemblies. The microchip-based sorting preserves the fidelity of the final product by enriching for flawless oligonucleotides, which leads to higher success rates in gene assembly and functional assays.

The synthesis component is then carefully orchestrated to build on the sorted, high-quality sequences by employing a localized, controlled chemical synthesis environment. By modulating the reaction conditions on the microchip, the system facilitates efficient extension and ligation of oligonucleotides, boosting both yield and sequence accuracy. This level of control is a significant advancement over bulk synthesis methods, which often suffer from inconsistent reaction kinetics and by-products.

Crucially, the recycling element of the principle closes the loop by reusing reagents and unincorporated nucleotide substrates, greatly enhancing the efficiency and sustainability of the process. This aspect reduces reagent consumption, lowers production costs, and minimizes waste, making the technology more environmentally viable for large-scale operations.

The implication of this research extends well beyond mere technical refinement. With the ability to synthesize DNA at higher concentrations and purity levels, scientists can now endeavor to construct longer and more complex genetic sequences with unprecedented ease and speed. This capability opens new frontiers in synthetic biology, such as engineering entire metabolic pathways, designing novel therapeutic genes, and creating synthetic organisms with bespoke functionalities.

Furthermore, the simplified downstream workflows reduce the barrier to entry for laboratories worldwide by decreasing dependency on expensive, highly specialized equipment and elaborate purification protocols. Smaller labs and startups focused on synthetic biology can leverage this technology to accelerate innovation without being hindered by resource constraints.

From an industrial perspective, the upscaling potential promises to transform the biomanufacturing sector by enabling commercial-scale DNA synthesis pipelines that are both cost-efficient and highly customizable. Applications spanning gene therapy, vaccine development, and biosensor fabrication stand to benefit immensely from rapid, scalable gene synthesis capabilities that keep pace with evolving research demands.

This microchip-based, massively parallel synthesis system demonstrates how the convergence of microfabrication, molecular biology, and chemical engineering can yield transformative tools that push the boundaries of what is possible in genomic science. By embracing an iterative mechanism that ensures product identification, high-fidelity sorting, effective synthesis, and sustainable recycling, the technology encapsulates a holistic approach to DNA manufacture that could soon become the industry standard.

The reported concentration increase by four to six orders of magnitude represents more than an incremental improvement; it is a quantitative paradigm shift enabling workflows and experimental designs that were previously impractical or economically untenable. Researchers anticipate rapid adoption of this method to expedite projects that involve large gene libraries, synthetic chromosomes, and complex gene circuits.

Moreover, the system’s modular design suggests flexibility in adapting to evolving synthesis chemistries and integration with emerging automated platforms. This adaptability will be crucial as the field of synthetic biology continues to expand into more complex territories requiring not just longer DNA sequences but also epigenetic modifications and sequence-specific functionalizations.

In summary, the breakthrough achieved by Zhang and colleagues ushers in a new era of DNA synthesis wherein scale, speed, and efficiency coalesce into a robust platform capable of sustaining the ambitious goals of synthetic genomics. The seamless fusion of identification, sorting, synthesis, and recycling not only addresses longstanding limitations but also lays down a versatile foundation for next-generation biotechnological innovation. This pioneering microchip-based system promises to accelerate the journey from digital DNA design to biological reality, powering discoveries and applications that will shape science and medicine in the decades to come.

Subject of Research: High-throughput and large-scale DNA synthesis technology using microchip-based systems.

Article Title: Scaling DNA synthesis with a microchip-based massively parallel synthesis system.

Article References:

Zhang, X., Jiang, X., Wang, Y. et al. Scaling DNA synthesis with a microchip-based massively parallel synthesis system. Nat Biotechnol (2025). https://doi.org/10.1038/s41587-025-02844-0

Image Credits: AI Generated