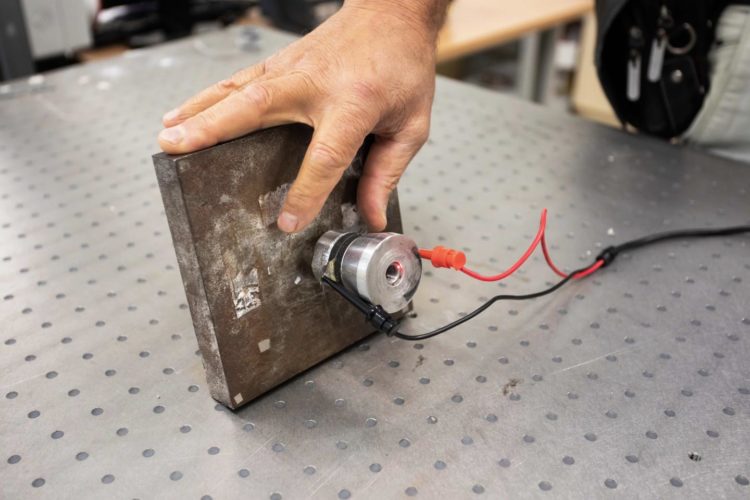

By experimenting with tungsten carbide a team of researchers at Kaunas University of Technology (KTU), Lithuania, created an innovative technology allowing to shape the extremely strong and yet easily breakable material into a desirable form.

Credit: KTU / Just? Šuminait?

A team of researchers at Kaunas University of Technology (KTU), Lithuania have developed a novel approach to precision grinding of hard and brittle materials achieving unparalleled efficiency of the process. By experimenting with tungsten carbide they created an innovative technology allowing to shape the extremely strong and yet easily breakable material into a desirable form.

High tech industry demand for high-performance optical components – from glass lenses for consumer products such as digital cameras to high-end products like medical systems – is increasing exponentially. In precision glass moulding, that allows the production of optical components from glass without grinding and polishing, hard and high-temperature resistant mould materials, such as tungsten carbide, are being used.

“Machining tungsten carbide in order to make the cylindrical details used in the moulding of optical elements is challenging. First, it is a very hard material, so any tool contacting with it is being worn almost instantly, second, if the tool is inserted too deep into the surface of tungsten carbide, the latter breaks. In order to be able to machine the hard and brittle material, it needs to reach plastic deformation state, when it can be shaped and formed without breaking”, explains Gytautas Balevičius, a researcher of KTU Institute of Mechatronics.

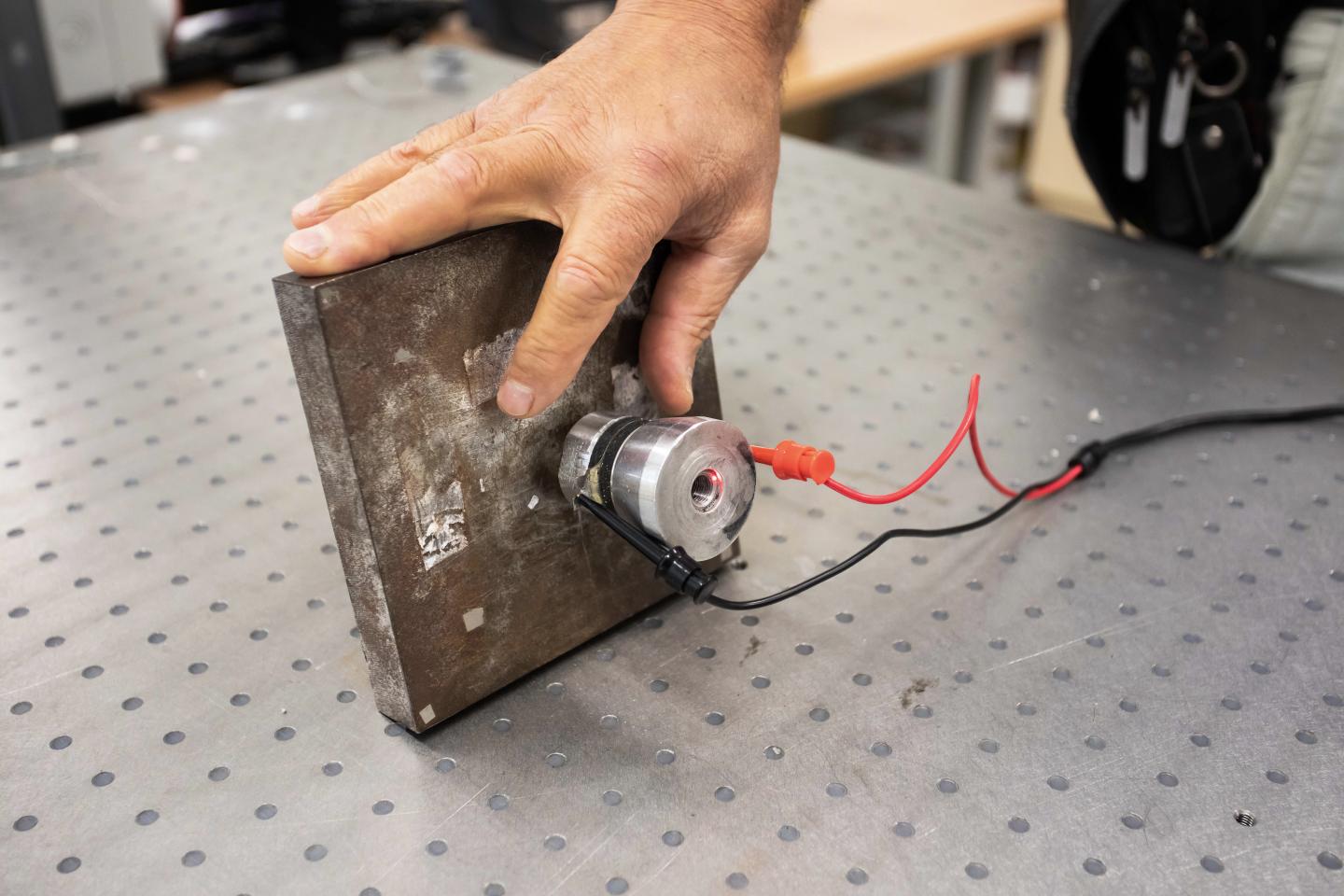

One of the ways to achieve the plastic deformation of the workpiece is the ultrasonic excitation of the tool. In other words – the tool starts vibrating and the vibration is transferred to the workpiece. The higher the frequency of excitation, the better the chances of achieving the state of plastic deformation of the material being ground. In a laboratory environment, it is possible to achieve the excitation frequency needed for plastic deformation using nano-scratching but so far it has been impossible to reach these frequencies in industrial conditions.

Although in the machining of the hard materials, such as tungsten carbide, diamond tools are being used, their wear in the process is significant. As the depth of the insertion of the tool into the surface can be only minimal, the process of the grinding is long and inefficient.

“We have proposed the novel approach to ultrasonically-assisted grinding. By focusing on the excitation of the workpiece rather than the tool, we have achieved the frequency of 80-100 kHz, which is currently very difficult to achieve in the industry worldwide”, says Balevičius, a PhD student at the KTU Faculty of Mechanical Engineering and Design, one of the authors of the invention.

The high frequency of the excitation allows achieving plastic deformation state of tungsten carbide workpiece, which means that the tool can be inserted deeper into the surface. This makes the process of grinding more efficient.

“High-performance optics is needed for the wide range of products, from every smartphone to the complicated tools used in medicine or astrophysics. By optimising the process of producing precision optics we are making a significant contribution to the high tech industry, placing Lithuania in the precision industries map”, says Professor Vytautas Ostaševičius, Director of the KTU Institute of Mechatronics, leader of the research group behind the invention.

3 innovative technologies have been created by KTU scientists in the process of this research. A patent application for the innovative equipment integrating these technologies has been submitted to the Lithuanian State Patent Bureau.

The commercialisation of the technologies and products created by KTU research groups is being facilitated by the KTU National Innovation and Entrepreneurship Centre, one-stop-shop for businesses and industry willing to cooperate with science.

###

Media Contact

Aldona Tuur

[email protected]

370-612-55857

Original Source

https:/