Process is developed to inhibit the fouling of desalination membranes with the addition of magnesium. Desalination stability is expected to improve process efficiency and lengthen the lifespan of membranes.

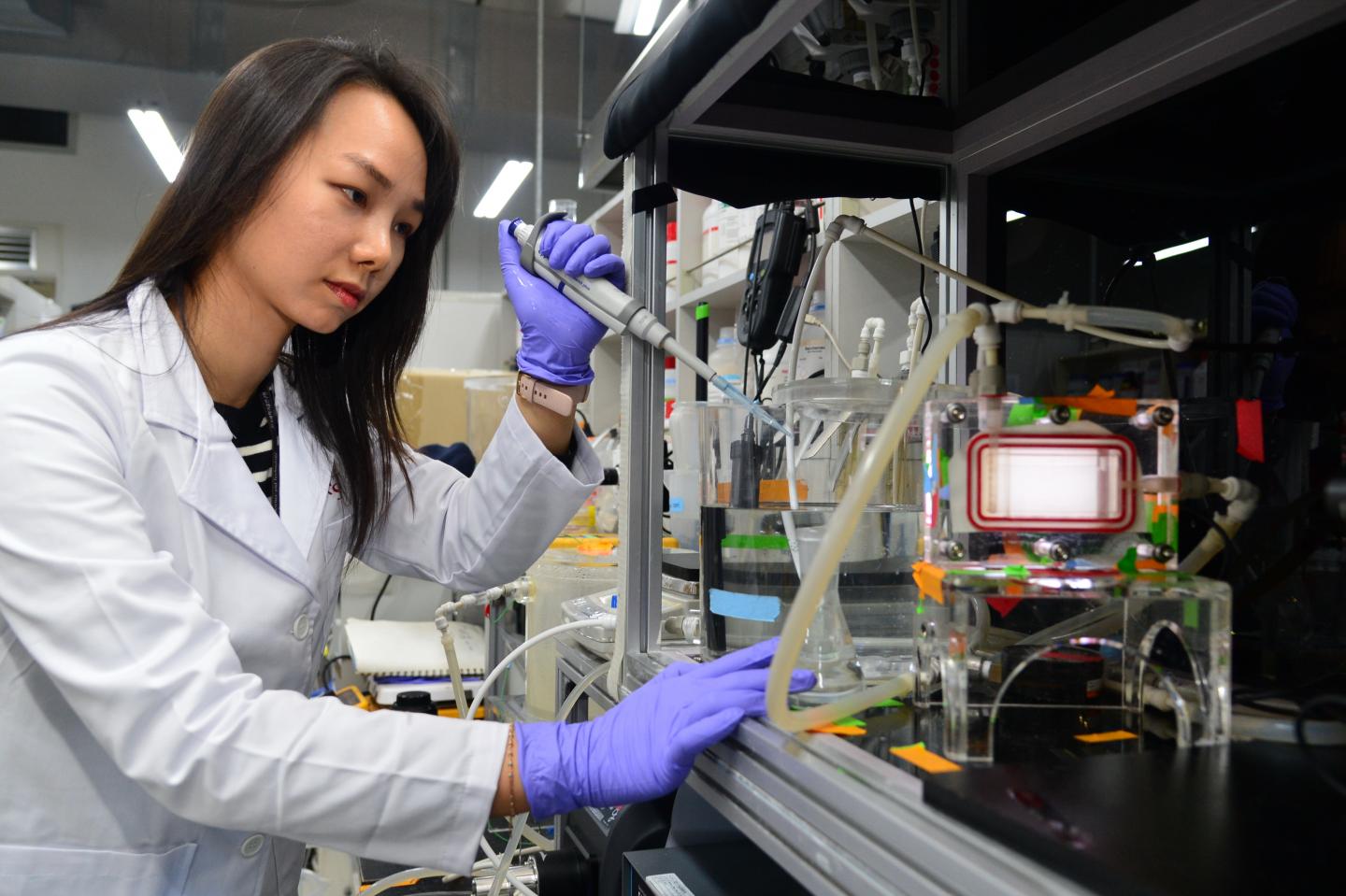

Credit: Korea Institute of Science and Technology (KIST)

A Korean research team found a method to inhibit the fouling of membranes, which are used in the desalination process that removes salt and dissolved substances from seawater to obtain drinking, domestic, and industrial water.

The Korea Institute of Science and Technology (KIST) announced that a research team led by Dr. Seongpil Jeong and Dr. Seockheon Lee at KIST’s Water Cycle Research Center developed a *membrane distillation pretreatment process that adds magnesium to inhibit the fouling and wetting of membranes during desalination.

*Membrane distillation (MD): A technology used to produce fresh water from seawater in which the seawater is heated to produce a vapor, which is then passed through a hydrophobic membrane that traps the salt and other particles to produce fresh water.

The membrane distillation process is a desalination technology used to produce fresh water in which seawater is heated to generate a vapor, which is then passed through a hydrophobic membrane before condensing into fresh water. The phenomena of **fouling and ***wetting can often occur during the membrane distillation process. If fouling occurs, it can cause the production of fresh water to take much longer or shorten the lifespan of the membrane used in the distillation process, thereby increasing the costs associated with freshwater production.

**Fouling: A phenomenon in which contaminants (particles, organic/inorganic matters) attach to or penetrate the membrane, resulting in membrane scaling

***Wetting: A phenomenon in which seawater directly passes through a hydrophobic membrane, which theoretically only lets vapor pass through

The KIST research team monitored the membrane distillation process and found that the formation of calcium carbonate (CaCO3) and calcium sulfate (CaSO4) crystals on the membrane surface was the main cause of fouling. They also found that the formation of CaCO3 crystals occurred at the beginning of the membrane distillation process, causing partial membrane wetting, while the formation of CaSO4 crystals caused a complete membrane wetting, halting membrane operation.

****Anti-scalants are often applied to prevent fouling caused by calcium-based crystal growth in the desalination process. There have been some reports in the industry about a chemical *****softening technology that can be applied as a pretreatment process for membrane distillation. However, it has also been reported that organic anti-scalants can reduce the surface tension of the feed solution and cause wetting. The application of chemical softeners, however, requires additional large-scale sedimentation and filtering processes to remove the crystals formed during the softening process.

****Anti-scalants: Chemicals that remove ions (calcium, magnesium) that can lead to the formation of crystals (scales)

*****Softening: Process of turning hard water into soft water by removing the calcium and/or magnesium found in the water.

KIST’s research team, led by Dr. Seongpil Jeong, is the first research team to ever develop a pretreatment process that adds magnesium to seawater. The team found that magnesium inhibits the formation of CaCO3 and CaSO4 and effectively prevents membrane fouling since the magnesium readily combines with the carbonate and sulfate ions in the seawater The team also found that the added magnesium chloride (MgCl2) increased the stability of the hydrophobic membrane, thereby increasing wetting resistance.

“Increasing the stability of the hydrophobic membrane is expected to help improve desalination efficiency and lengthen the lifespan of the membrane,” said Hye-won Kim (first author of Water Research (Vol. 175 (2020) 115677)) at KIST. “The mineral-based, environmentally-friendly pretreatment is applicable not only to the membrane distillation process but also to various other desalination processes.”

###

The research was conducted as a Ministry of Environment Plant Research Project and as one of Institutional Research Program of the Korea Institute of Science and Technology. An article explaining the results of the research was published in the latest issue of Water Research (IF: 7.913, top 0.549% of JCR).

Media Contact

Do-Hyun Kim

[email protected]

Related Journal Article

http://dx.