In the automotive industry, the integration of advanced manufacturing technologies is reshaping traditional processes and proposing groundbreaking methodologies that enhance not only efficiency but also functionality. A notable contribution in this realm, as outlined by researchers Lorenz and Mayer, focuses on the automated manufacturing of wiring harnesses through the lens of additive manufacturing. This innovative approach addresses longstanding manufacturing challenges by merging functional components in unprecedented ways, paving the path towards a new era of automotive engineering.

The conventional process for creating wiring harnesses has been labor-intensive and fraught with inefficiencies. Traditionally, numerous separate components must be painstakingly assembled into a functional unit, leading to higher labor costs and longer production times. With the integration of additive manufacturing processes into these workflows, manufacturers can potentially revolutionize how wiring harnesses are produced by eliminating several steps involved in traditional manufacturing methods, thereby streamlining operations significantly.

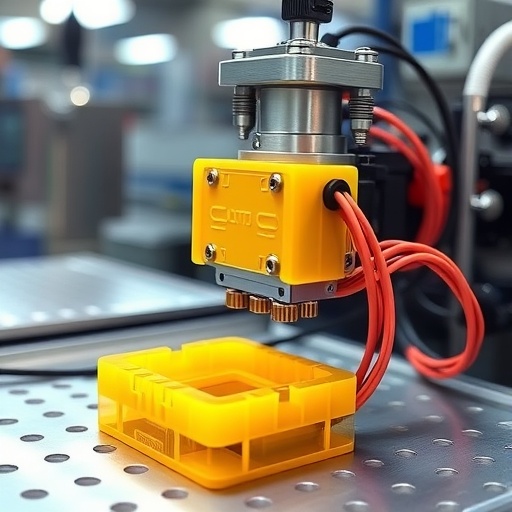

At the forefront of this development is the concept of function integration, which leverages the ability of additive manufacturing technologies—such as 3D printing—to produce intricate designs that combine multiple functions into a single component. Such integration not only simplifies the assembly process but also enhances the performance characteristics of the wiring harness itself. By utilizing this strategy, manufacturers can create components that are lighter, more durable, and ultimately more reliable, which are crucial attributes in the automotive industry.

Additive manufacturing allows for the customization of products to meet specific requirements without incurring significant costs associated with traditional manufacturing setups. This capability is particularly beneficial in automotive production, where tailored components can lead to improved performance metrics and a more cohesive vehicle design. The adaptability of additive manufacturing facilitates rapid prototyping, enabling manufacturers to quickly test and iterate designs—reducing the time from concept to production.

Moreover, automating the wiring harness assembly process brings an element of consistency that is often lacking in manual methods. Automation minimizes human error and variability, ensuring that every component meets stringent quality standards. This consistency is critical for automotive applications, where the reliability of wiring harnesses can directly impact vehicle safety and performance. The research undertaken by Lorenz and Mayer indicates that through automation, manufacturers can significantly boost their production capabilities while maintaining high safety and quality standards.

Despite the numerous advantages, some challenges remain in the widespread adoption of additive manufacturing for wiring harness production. Research indicates that there are difficulties associated with materials compatibility, sustainability, and the initial investment in new technologies and training for personnel. However, the promise of reduced lead times and increased customization opportunities often outweighs these hurdles. The ongoing research by Lorenz and Mayer not only aims to address these concerns but also to provide concrete solutions as the industry transitions toward these advanced methods.

Another pivotal aspect of this research explores the interplay between additive manufacturing and industry 4.0. The concept of Industry 4.0 encapsulates the rise of smart manufacturing that employs intelligent systems and data analytics to improve production processes. By integrating adaptive manufacturing setups into smart factories, manufacturers can optimize production schedules based on real-time data, increase production flexibility, and improve their supply chain management—providing a holistic approach to automotive manufacturing that aligns with contemporary technological advancements.

Collaboration across disciplines becomes paramount as researchers and manufacturers navigate this new landscape. Engineers, materials scientists, and manufacturing experts must concertedly work together to develop comprehensive solutions that enhance the capabilities of additive manufacturing for wiring harness creation. This collaborative approach can lead to innovations in material science, with the development of new, lighter, and stronger materials that are suitable for the unique demands of automotive applications.

Furthermore, as the automotive landscape shifts to embrace electrification and autonomous vehicle technologies, the need for advanced wiring harness systems becomes increasingly critical. The dynamic environment necessitates more complex and sophisticated wiring harnesses that can accommodate the myriad of sensor technologies and electronic components that modern vehicles integrate. Additive manufacturing not only addresses the production challenges associated with these complex wiring systems but also supports the evolving requirements of electric and autonomous vehicles.

As we look ahead, the fusion of traditional manufacturing expertise with cutting-edge technologies like additive manufacturing signals a transformative shift in how wiring harnesses are approached and produced within the automotive sector. This transformation speaks to a broader trend where industries are not merely adapting to change, but actively pursuing innovation that redefines the status quo. The outcomes of Lorenz and Mayer’s research serve as a guiding light for this paradigm shift, offering a pathway for manufacturers to embrace the future of automotive production.

Ultimately, the research by Lorenz and Mayer emphasizes the urgent need for the automotive industry to advance beyond its established methods of production. The integration of additive manufacturing into wiring harness manufacturing stands out as a viable solution to many prevailing issues in the industry, promising better productivity, enhanced innovation, and improved vehicle performance. As the automotive world is poised on the cusp of a major transformation, the methods explored in this research could become foundational to the future of manufacturing.

In conclusion, the innovative approaches presented in the research by Lorenz and Mayer highlight a critical movement within the automotive manufacturing landscape, where traditional practices are being reevaluated and enhanced through the adoption of new technologies. The insights gathered from this investigation into automated wiring harness manufacturing not only pave the way for enhanced operational efficiency but also herald a future where the possibilities of automotive design and functionality are limited solely by the extent of human imagination.

As the industry anticipates the widespread application of these techniques, it is clear that the automotive sector stands on the brink of an extraordinary evolution, one marked by the integration of automation, additive manufacturing, and smart technologies that promise to rewrite the rules of automotive engineering for generations to come.

Subject of Research: Automated wiring harness manufacturing via additive manufacturing.

Article Title: Approaches for automated wiring harness manufacturing: function integration with additive manufacturing.

Article References:

Lorenz, N., Mayer, R. Approaches for automated wiring harness manufacturing: function integration with additive manufacturing.

Automot. Engine Technol. 8, 227–237 (2023). https://doi.org/10.1007/s41104-023-00137-9

Image Credits: AI Generated

DOI: 10.1007/s41104-023-00137-9

Keywords: Additive manufacturing, wiring harness, automation, automotive engineering, function integration, manufacturing efficiency, Industry 4.0, electric vehicles, smart manufacturing, material science.

Tags: additive manufacturing in automotive industryadvanced manufacturing methodologiesautomated wiring harness productionchallenges in wiring harness manufacturingefficiency in wiring harness assemblyenhancing performance characteristics of componentsfunctional integration in manufacturinginnovative automotive engineering solutionsintegration of 3D printing technologieslabor cost reduction in manufacturingmerging functional components in manufacturingstreamlined production processes in automotive