For over 450 million years, sharks have navigated the ocean’s depths, evolving a unique skeletal system fundamentally distinct from that of most vertebrates. Unlike animals built from bone, sharks possess skeletons composed primarily of a tough, mineralized form of cartilage. This evolutionary adaptation provides a remarkable combination of strength and flexibility, enabling these apex predators to sustain the relentless physical demands of swimming with fluid grace and power. Recent advances in nanoscale imaging have now begun to unveil the intricate architectural design inside shark vertebrae—an internal world that could inspire revolutionary developments in material science.

Scientists employing synchrotron X-ray nanotomography have succeeded in visualizing the internal structures of blacktip shark cartilage at an unprecedented level of detail. This technique, combined with in-situ mechanical testing, reveals the complex nanoscale arrangements of collagen and mineral components that reinforce the shark’s skeleton. By collaborating across disciplines and institutions—including Florida Atlantic University, the German Electron Synchrotron (DESY), and NOAA Fisheries—researchers have unlocked insights into the microscopic “sharkitecture” that confers exceptional resilience and adaptability to the shark’s frame.

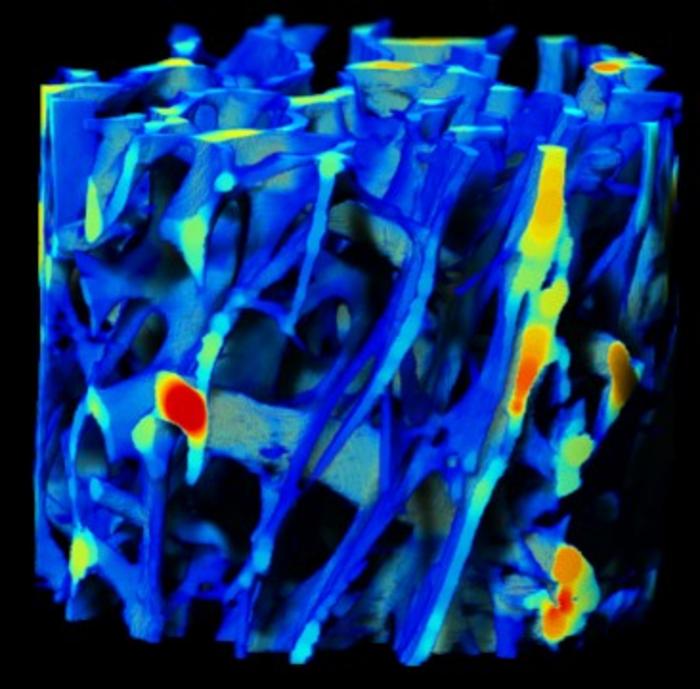

The vertebral cartilage of the blacktip shark is composed of two distinct regions: the corpus calcareum and the intermediale. Both regions comprise densely packed collagen fibers mineralized with bioapatite, a needle-like crystalline mineral also found in human bones. Despite compositional similarities, their internal architectures differ markedly. Porous mineral plates arranged in a sophisticated lattice, reinforced by thick struts, enable the shark’s skeleton to endure mechanical strain from multiple directions. This is crucial for a species whose constant swimming rhythms impose repeated and multidirectional stress on vertebral structures.

At the nanoscale, the collagen fibers and bioapatite crystals are not merely randomly distributed. Instead, bioapatite needles align closely with collagen strands in a highly ordered fashion. This interplay of organic and inorganic components creates a composite material that is both surprisingly strong and flexible—a delicate balance that allows shark cartilage to perform mechanical feats that traditional bone structures often cannot emulate. The resultant biomineralized cartilage exhibits an efficiency born from millions of years of evolutionary refinement.

Perhaps most fascinating is the discovery of helical collagen fiber arrangements woven within the mineral matrix. This layered, spiral architecture acts as a formidable barrier to crack propagation, effectively arresting fractures before they escalate into catastrophic failures. Under mechanical stress, the collagen and mineral networks synergistically absorb and dissipate force. This intricate design not only contributes to the shark’s endurance during high-speed swimming but also protects the structural integrity of its vertebrae over time.

Mechanical testing on microscopic samples of mineralized shark vertebrae revealed that minor deformations occur after just one loading cycle—typically under a micrometer in magnitude. Notably, actual fractures manifested only after repeated loading. More importantly, these fractures remained confined within a single mineralized plane. This intrinsic limitation on crack spread underscores the cartilage’s built-in resistance to mechanical failure, a property that has significant implications for developing impact-resistant materials.

Beyond the fundamental biological insights, this research adds to our biomechanical understanding of shark skeletons—organ systems uniquely tuned for strength, flexibility, and endurance. Researchers like Marianne Porter, Ph.D., of Florida Atlantic University’s Biological Sciences Department, highlight the value of deciphering how mineral and collagen networks unite at the nanoscale. Their findings could guide the development of synthetic materials engineered to exhibit similar toughness and flexibility, traits highly sought after in both biomedical and industrial applications.

Blacktip sharks themselves are remarkable creatures, renowned for their agility and speed in warm, shallow coastal waters across the globe. Their capacity to leap and spin dramatically from the water during feeding exemplifies the extraordinary functional demands placed on their musculoskeletal systems. Insights gleaned from their nanoscale cartilage structures may thus translate into innovations not only in materials science but also in robotics and biomechanical engineering.

The investigation’s interdisciplinary nature—drawing on expertise in chemistry, engineering, biology, and high-resolution imaging—further underscores the power of collaboration in scientific discovery. Stella Batalama, Ph.D., dean of Florida Atlantic University’s College of Engineering and Computer Science, remarks on how such synergy accelerates breakthroughs, especially in understanding and replicating nature’s complex materials. The layered, fiber-reinforced structure of shark cartilage offers a compelling template for next-generation materials that balance durability with adaptability.

Funding for this pioneering work was provided by several prestigious sources, including the U.S. National Science Foundation and institutional seed grants. The research team brought together seasoned scientists and emerging scholars—a testament to the vitality of academic training combined with cutting-edge technology. Such studies bridge the gap between fundamental biological exploration and practical engineering applications, offering a route toward biomimetic materials that could reshape fields ranging from medical implants to protective gear.

Florida Atlantic University, known for its strong emphasis on interdisciplinary research and innovation, continues to lead efforts in unraveling nature’s complex engineering feats. With their work published in the esteemed journal ACS Nano and supported by globally recognized facilities like DESY’s PETRA III X-ray light source, the researchers have set the stage for future explorations into the nanoscale mechanisms underpinning biological resilience. Their findings herald a new era in understanding skeletal biology and material design inspired by sharks’ enduring evolutionary success.

Subject of Research: Animals

Article Title: A Nanoscale View of the Structure and Deformation Mechanism of Mineralized Shark Vertebral Cartilage

News Publication Date: 7-Apr-2025

Web References:

ACS Nano Article DOI

Florida Atlantic University College of Science

Florida Atlantic University College of Engineering and Computer Science

Florida Atlantic University

References:

Merk, V. et al. (2025). A Nanoscale View of the Structure and Deformation Mechanism of Mineralized Shark Vertebral Cartilage. ACS Nano. DOI: 10.1021/acsnano.5c02004

Image Credits: Florida Atlantic University

Keywords

Materials engineering, Bioengineering, Mechanical engineering, Marine resources, Industrial chemistry, Biotechnology, Synthetic biology, Microtechnology, Nanotechnology, Nanofabrication, Nanoscopy, Chemistry, Materials science

Tags: bioapatite in shark anatomyblacktip shark skeletoncollagen and mineral structures in sharksinterdisciplinary shark research collaborationmarine biology and material innovationmechanical testing of shark cartilagenanoscale imaging of cartilageresilience of shark skeletonsshark evolutionary adaptationssharkitecture in material sciencesynchrotron X-ray nanotomographyvertebral cartilage composition